Over the last few weeks my project has undergone several design changes. The purpose for these changes is mainly to allow for the bed to be able to fully collapse enough to fit completely behind the last row of seats in my car. The original design folded into two sections, allowing for ease of manufacturability, and still allows the middle row of seats in my car to sit back up when folded away. I liked the previous design because it was rather simple and didn’t require much hardware. Simply put, the new design is neither of those things.

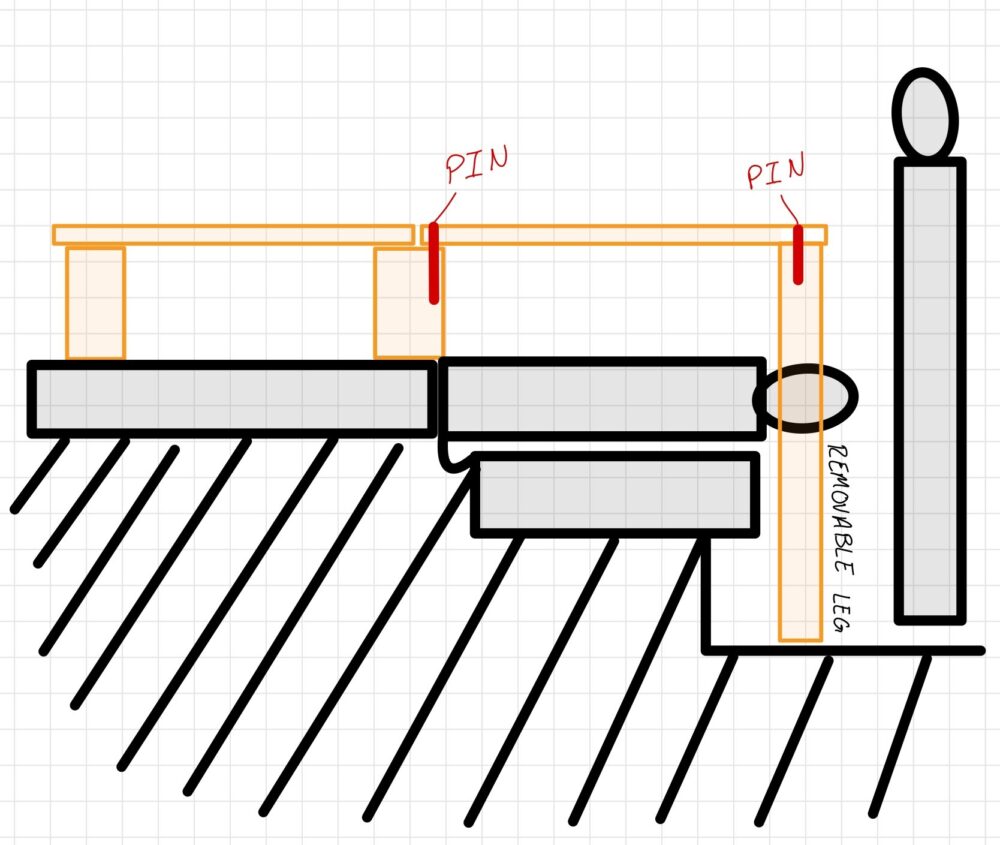

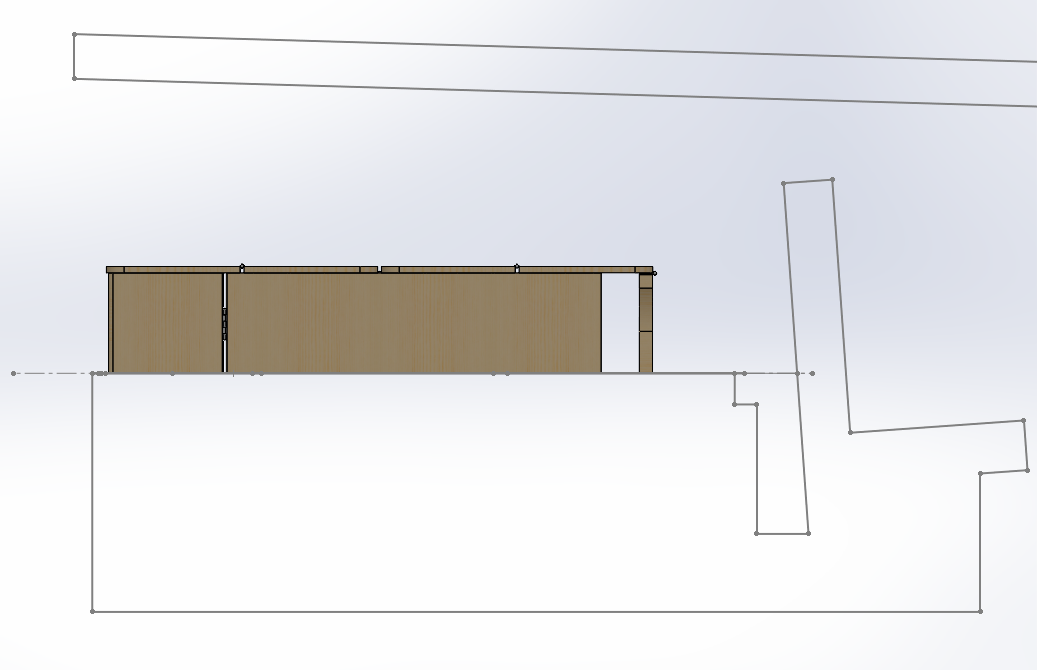

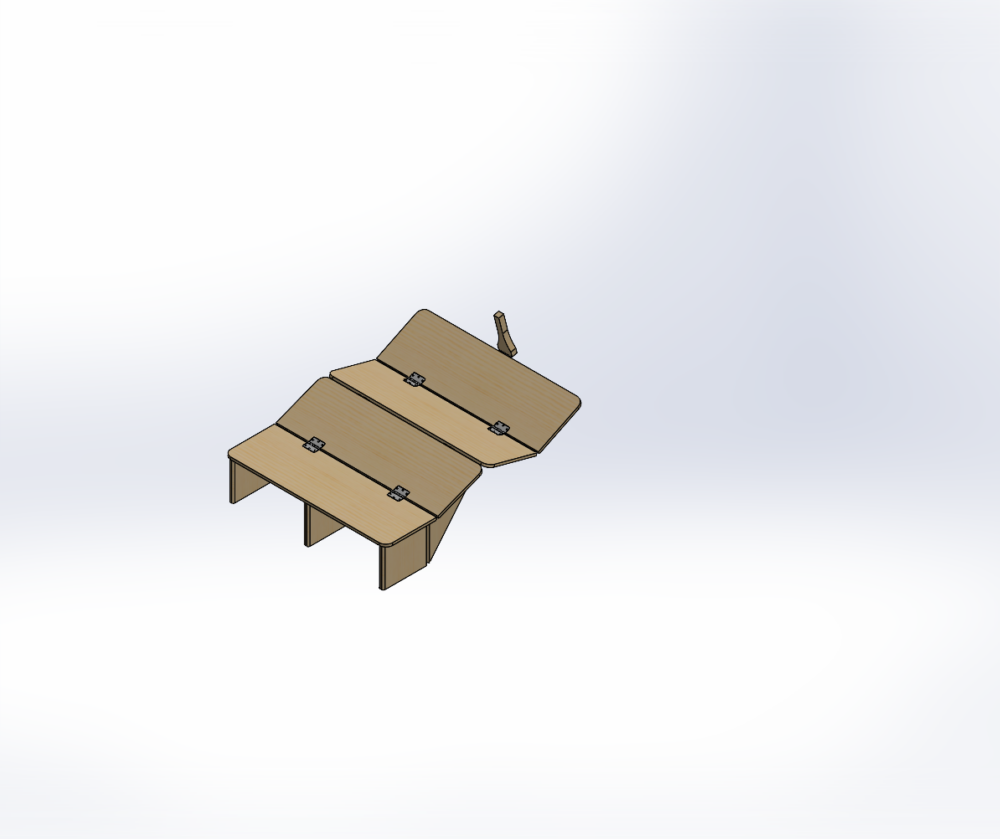

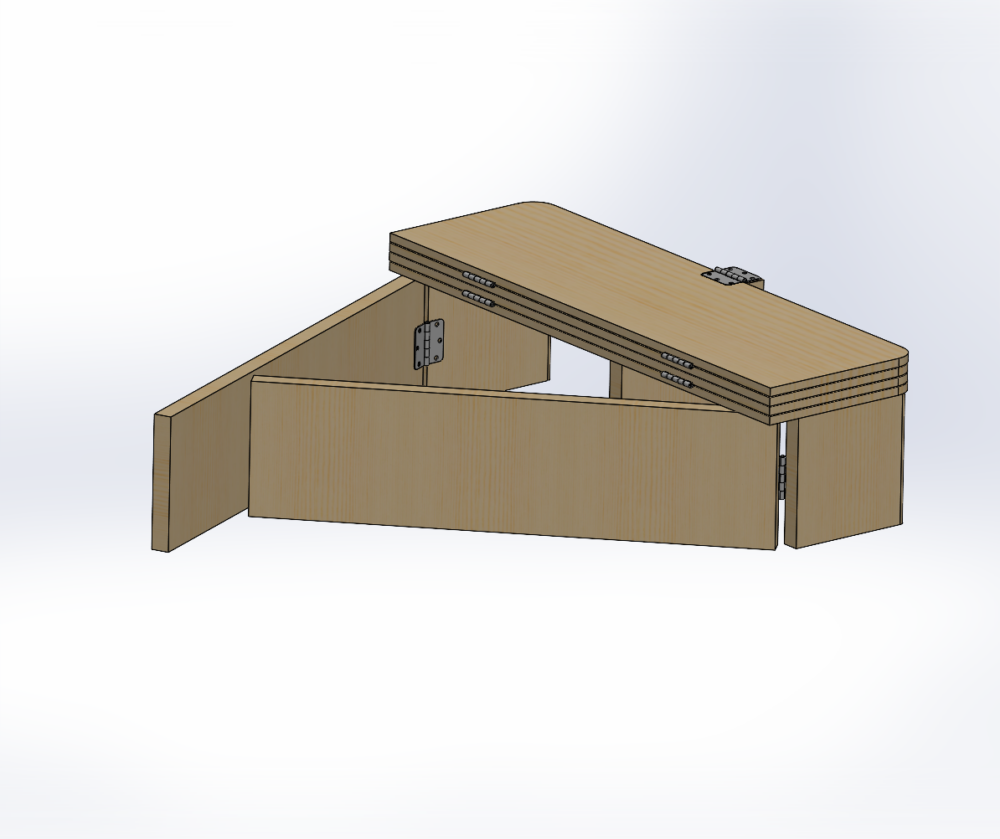

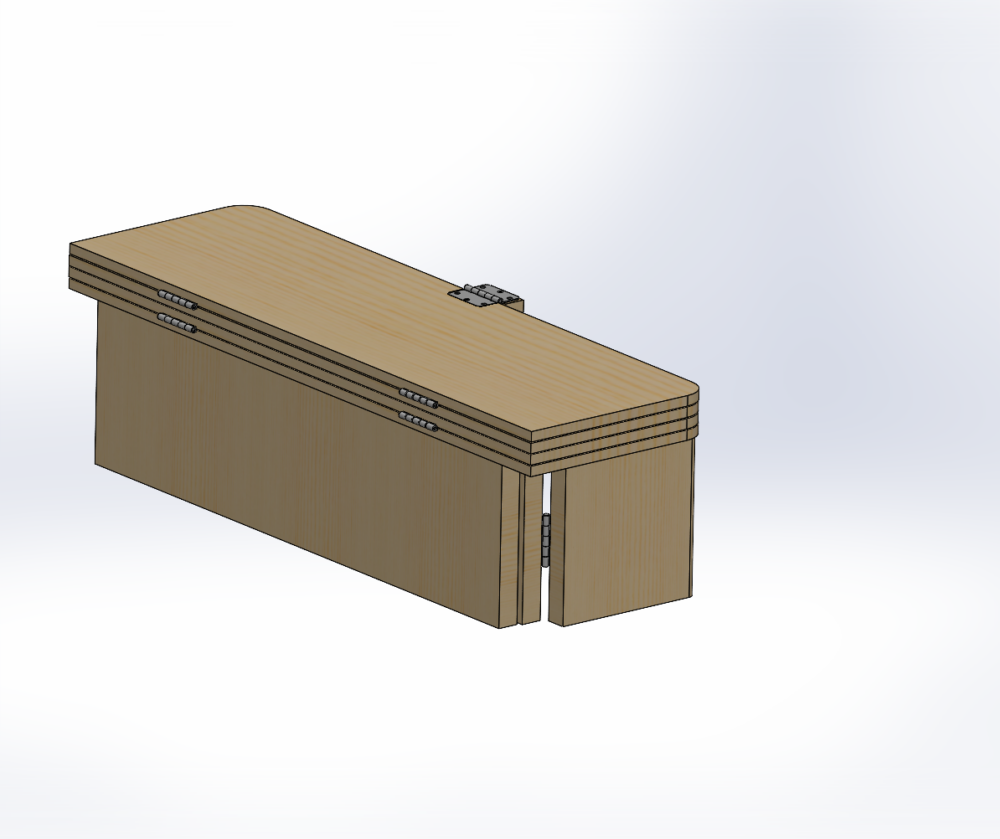

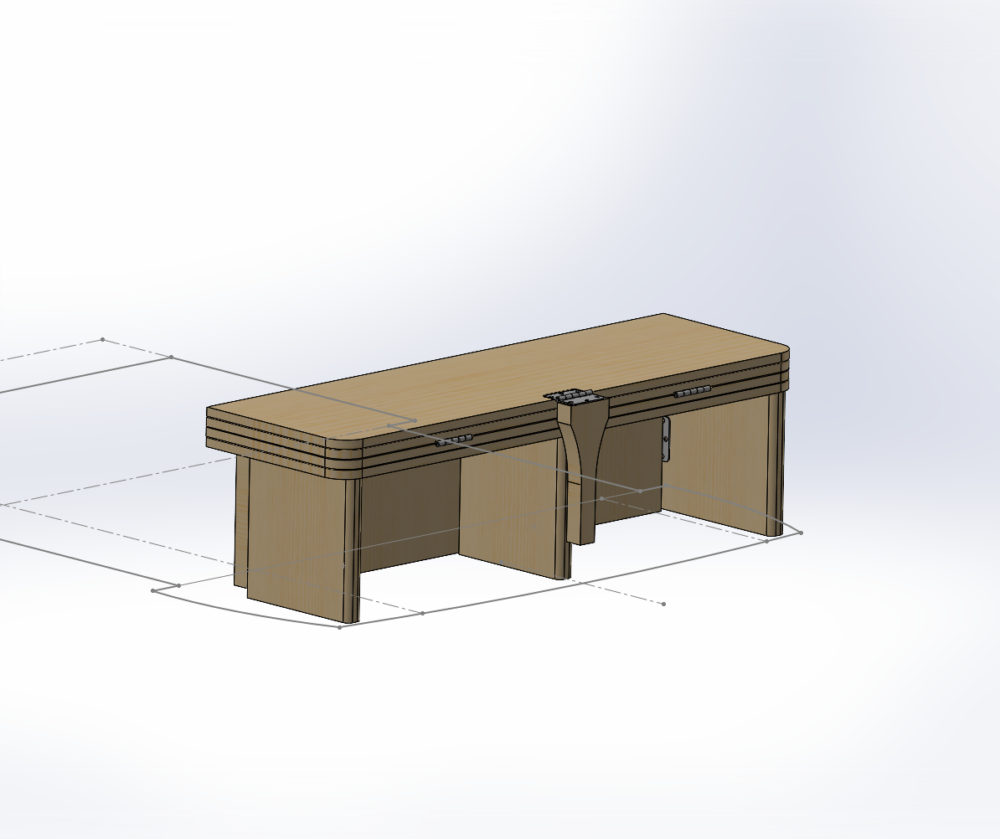

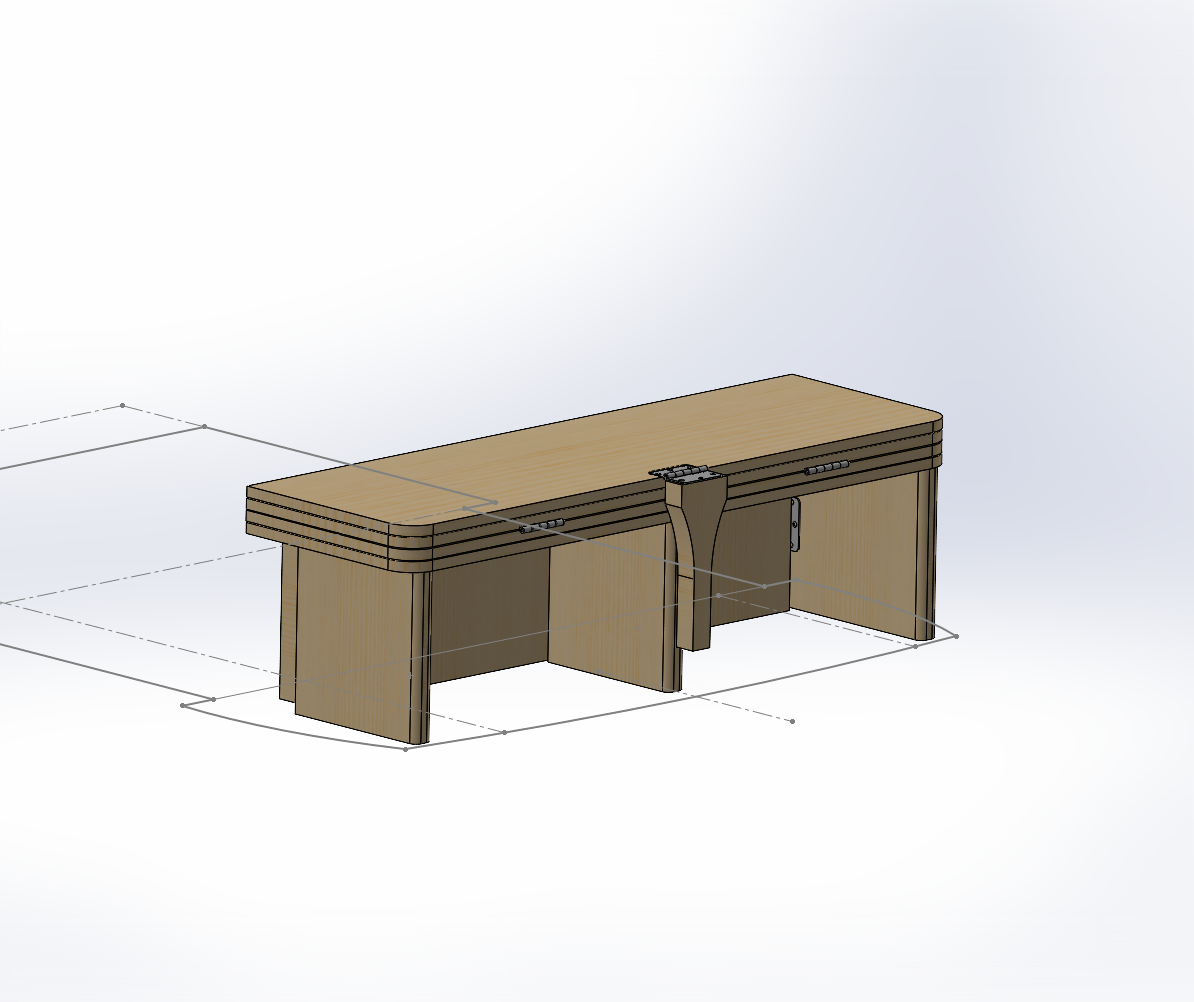

The old design is on the left and the new design is on the right. What the older drawing does not display is that there is a second folded row of seats behind the first folded row. In order to solve this the two panel design was traded not with a three panel design, but a design with four panels. This was done because when taking measurements of my car I found that my seats laid down longer than the pure trunk space. So, to get this all to fit in just the trunk space, each panel has to be smaller than just one seat.

This new design uses hinges, which is now much easier to use because the panels are short enough to easily fold within the confines of the car’s ceiling. The old design was too long to comfortably fold within the height of the car. Unlike the old design there are no parts that are removed when folded. Instead, the supports fold back into the back of the structure when folded, allowing it all to be much more self contained.

All these redesigns have left little room for actual construction. However, I have been able to find most of my materials. My friend had a lot of pre-stained .5″ plywood that I can use for all of my flat panels, and I was able to find a cheap 10 pack of hinges from home depot. All I need is a 2″x12″x12′ board for the supports and I can cut everything to shape.

4 Comments. Leave new

Hey Alex, I love how you’re adapting the design to fit your space constraints. The transition to a four-panel system makes a ton of sense, especially with the folding ceiling issue. It’s super smart that you’re keeping everything self-contained now, too; no extra parts to lose seems like it’ll be more efficient. Have you thought about adding any locking mechanisms or magnets between panels to keep it extra sturdy when laid out?

Hi Matt, I have not thought about any sort of locking mechanisms, to be honest. There is definitely a chance that this ends up being very wobbly. I will probably add features like this later, only if they end up being necessary. I think the most important part for now is getting the basics I have done in time.

Hi Alex. Your CAD model looks great! I’m excited to see how your project turns out. Sounds like you’ve got all of your material set up and sourced from friends! Lucky! I appreciate your design choices a lot, especially looking at the 2D sketches of how this is all going to come together. Well done!

Thanks! I definitely got lucky that my friend had something that I could use.