Featured photo: telescoping inspiration from Camping World

For my dynamic shuttle bus bed frame, there are several things I have in mind that will make it a successful project, both aesthetically and functionally. Additionally, there are a lot of constraints that I will need to work around to ensure that this project meets these requirements. I will start by discussing the top 5 specifications.

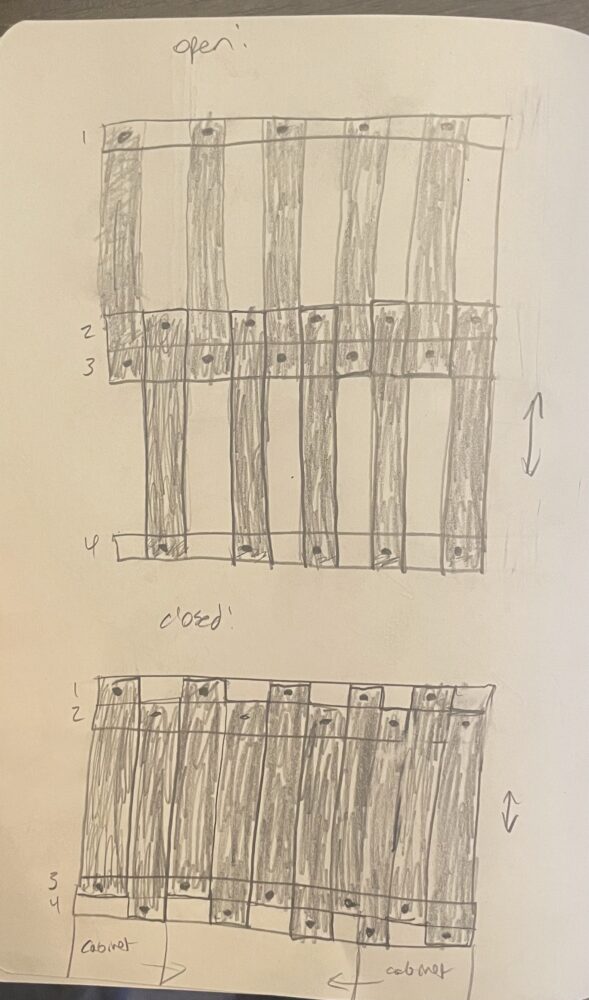

Specification 1: Telescoping Component

This is the number one thing that I envisioned when I first set up this project, and it is the main thing I want to be able to achieve at the end. For this to happen, I need to precisely interlock the wooden slats that will be able to slide into each other. This means that I will need to have sufficient clearance between each interlocking slat.

Specification 2: Frictionless Sliding (photo from Vevor)

Along with the telescoping slats, I want this mechanism to be as smooth and frictionless as possible. To achieve this, I plan on using a Vevor sliding system. I have discussed this linear sliding system with peers who have used it in the past, and I have learned that proper alignment is critical. For this reason, I will be using measurement to verify that the spacing/linearity of the two corresponding rails is within 1/8″.

Specification 3: Built-in Dresser (photo from Home Depot)

I really wanted to make a modular storage component for this project, so it is important that I integrate some sort of drawer system. I plan on integrating dressers under the bed and making them structural supports that can also be used to organize items underneath the bed.

Specification 4: Able to bear a 400 lb dynamic load

This bed will be low profile to both adhere to the minimalist aesthetic and also keep the bulkiness down for my overall shuttle bus build. However, I still need to make sure it is structurally intact and able to hold at least 2 people (~400 lbs) when the bus is driving. For this reason, all of my components need to be rated to at least this, and I need to ensure that the materials I use can support stresses that result from this loading.

Specification 5: Matching color theme

To maintain my naturalist and minimalist aesthetic, I would like to match all possible wood components to my trim and ceiling color in the bus. This will maintain a consistent color flow and help the bed fit in simply with the space. I already have the correct color paint, so I just have to paint whatever wood supports I use with this color.

Constraint 1: Width of Bedframe/Dimension of Cabinets

The first constraint for this build will be the width of the bedframe. The bedframe needs to fit in the back corner of my bus, and this dimension is constrained by the wheel wells. These are about 56″ from the back of the bus, which is perfect because a full bed is 54″. I want the overall width of the frame to be 55″ to give room for the bedding on top and also floor room to continue kitchen cabinets next to the bed frame. With this, I want to find cabinets that are about half of this dimension, so that when the bed frame is collapsed in half, they are able to be accessed but they can also provide structural support up to the middle of the width of the bed.

Constraint 2: Length of Bedframe/Length of cross beams

The length of the bedframe is constrained to the width of the interior of the bus. This is about 76″ in length, and a full bed extends 75″. This means I should build right up to the walls with the frame with no corner obstructions. This means that I will have to cut the 4 crossbeams to precisely this length, so that they are able to cover the full length of the bed without interfering with the walls.

Constraint 3: Thickness of Runner Beams

The thickness of the running beams need to be sufficient size to support the Vevor sliding tracks. These tracks are just under 3″, so I need at least 3″ thick runners.

Constraint 4: Gas Nozzle Block

The gas tank nozzle sticks into the interior of the bus. I have covered this up with a wooden box, but this will be poking into the cabinet area. This means I will have to modify one of my cabinets to account for this protrusion. I will need to get an exact measurement to ensure a clean cut for this. I plan on using the woodshop in the ITLL.

Constraint 5: Height of Bedframe

My final constraint is the bedframe height. I have a window in my bus that I do not want to be obstructed by the bed. The window starts at 36″. The average mattress is about 6″ tall, so I need the frame to go no higher than 30″. This will be contingent on my cabinet selection, so I need to make sure my cabinets are at this height.

2 Comments. Leave new

Wow, this is a really cool idea. Making sure everything is properly aligned and slides together smoothly is going to be quite difficult it seems. I know a lot of people who have built out their vans / busses and it looks really good, they just had to put a lot of time into it. This is going to be really cool, and I can’t wait to see the final product.

Hi Kalin, thanks for the feedback! I have heard the sliding rails need to be aligned with a good amount of precision to function properly, so I am going to pay extra attention to this. I plan on fixing the rails down temporarily first, then checking if the rails slide okay to ensure that everything is straight before permanently fixing the rails.