As my main project for this class, I’m working on converting a 1907 Waltham Grade 165 pocket watch movement into a functioning wristwatch. The process has been challenging but rewarding, and at this point, I’ve been thinking more critically about what exactly I want this final piece to look like, feel like, and do, and what stands in the way of getting there.

Top 5 Things I Want This Watch to Be

- A Showcase of Pre-Modern Design

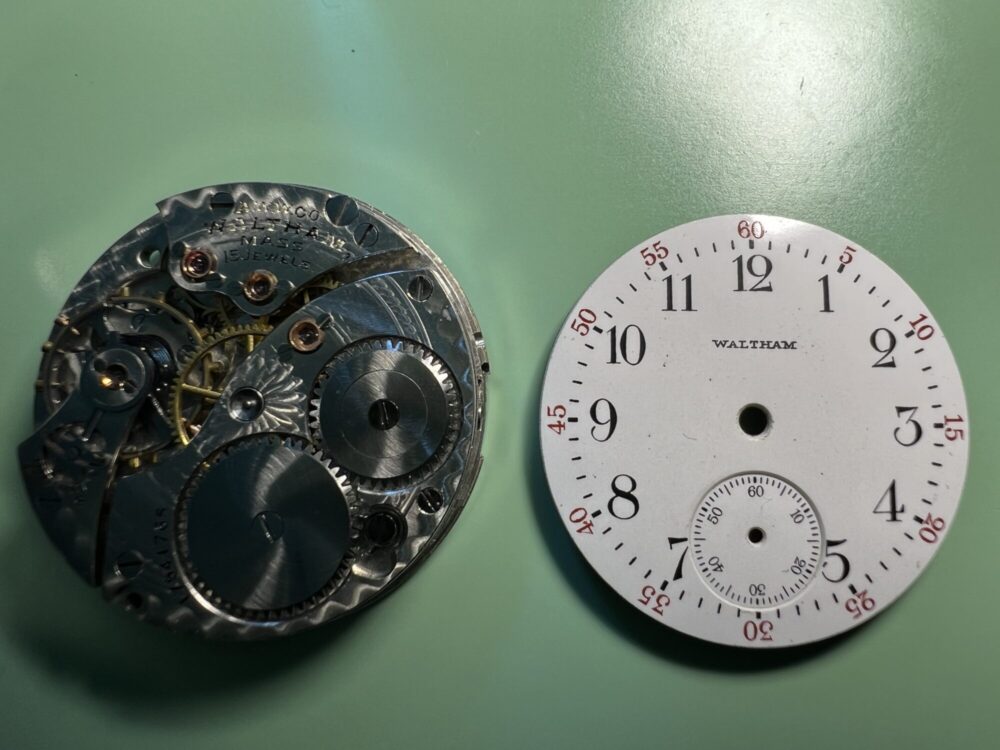

Aesthetically, I want this project to reflect the beauty and craftsmanship of pre-modern industrial design. The movement is already full of character, with hand-engraving and a brilliant enamel dial, so my goal is to highlight that. I’m using a generic dive-style case I sourced from AliExpress, not ideal stylistically, but it has a clear caseback, which is a great feature for showing off the movement and its easier to work with than manufacturing an entire case from scratch. I’ll also be using a leather strap instead of a metal bracelet to avoid making it look too modern. - Comfortable and Practical to Wear

I want this to feel like a normal wristwatch, not a novelty item. The size, weight, and proportions should be appropriate for daily wear, even if the internals date back over a century. - Function Like a Modern Watch

Functionality is a major priority. I want the watch to keep good time, be hand-windable, and ideally be waterproof. It doesn’t need to be rated for diving, but I’d like it to be durable enough to wear in everyday situations. - Physically Well-Integrated

I’ll consider this a success if the movement fits perfectly into the case with no rattling or shifting. The stem and crown should work smoothly, including hand setting and winding. Most importantly, the crown shouldn’t fall out when it’s pulled to set the hands, an issue I’m working to avoid. - Functionality Above All

While I love the aesthetic and historical aspect of this project, the most important priority is that it works. If I can create something that runs reliably and wears comfortably, I’ll be happy.

Top 5 Constraints I’m Facing

- Machining Access and Error Margin

One of the biggest hurdles so far has been machining the case. I recently tried milling one of the watch cases I bought to experiment with and accidentally removed too much material, damaging the part of the case that holds the dial. I had to scrap that case entirely. Getting machine time at the ITLL is hit or miss as there’s usually a long wait since many students are working on final projects. - Crown Compatibility Issues

The dive watch cases I ordered have screw-down crowns, which are interfering with the vintage stem sleeves I sourced for the conversion. The screw-down design includes an internal shaft and o-ring that blocks the stem sleeve, making it hard to get everything to fit properly. I’m considering switching to a different case type without a screw-down crown or possibly modifying the crown itself. There’s also the concern that the screw-down design might interfere with smooth hand-winding, since the movement is not automatic. - Shipping Delays

Most of the generic watch cases I’ve been using come from China, and shipping times can be long. If I damage the current case while machining, I may need to place another rush order which could delay the project significantly. - Movement Issues

Right now, the movement isn’t winding, which means I need to take it apart and diagnose the issue. I’ve already serviced the movement once, but something seems to be preventing the mainspring from tensioning. Until that’s fixed, I can’t proceed with final assembly. - Time Pressure

Between waiting for machining access, troubleshooting the crown, and resolving the winding issue, time is becoming a constraint. Each delay adds pressure, especially with the semester winding down.

Final Thoughts

I’m feeling a bit anxious about getting everything done in time, especially finding machine time and resolving the crown problem, but I’m still optimistic. I’ve already learned a lot from the setbacks, and I’ve figured out how to machine the next case properly, which helps. The crown is still a puzzle, but I’m exploring solutions and staying flexible.

In the end, I want this watch to be a fusion of historical craftsmanship and modern functionality. If I can get it running smoothly, wearing comfortably, and showing off the beauty of the movement, I’ll consider the project a success.

2 Comments. Leave new

Hi Robert, this is such a wonderful idea and it seems like you’ve made a lot of great progress! I am designing a clock myself, so I love seeing your watch and how you’re organizing your specifications and constraints.

One question I have is, have you considered designing your own watch case for the mechanism? You mention that you want to focus on how your watch looks and feels now, and this could be something to consider! You could 3D print the material once you’ve designed or modeled it or possibly laser cut layers! Maybe even putting that on top of the existing case? I recommend looking at Andrew Song “asocreate” on Instagram. He does a Casio watch face design and his designs are incredible in how they look and feel.

Best of luck finishing up your design!

Hi Robert, this sounds like an awesome project! I like how you have broken up your specifications into mostly functionality and style. It seems like function is the most important part and I’m curious about the movement winding issue. Is this a hard problem to solve? It would be very interesting to learn how to fix watches like this. I also hope you can get on another mill soon. Good luck with the rest of your project!