When envisioning my custom longboard cruiser project, there are five key qualities that I’m prioritizing to ensure success. Firstly, I aim for the finished deck to mirror the professional appearance of store-bought products, with uniform edges and impeccable finishing details. Secondly, durability is crucial; I need the deck to withstand common wear like razor tail and edge impacts from curbs, preserving both functionality and aesthetics. Thirdly, ensuring strength around the screw mounts to prevent pull-through is essential for safety and longevity. Fourth, I want the board to evoke a nostalgic vintage surf and skate aesthetic, capturing a sense of heritage and classic style. Lastly, incorporating slight flexibility is vital—I envision a responsive yet sturdy deck that provides just the right amount of give without the risk of breaking when pressure is applied.

Recognizing my constraints is equally important. My most significant challenge is budget; I have only one opportunity to purchase the necessary materials, meaning precision and careful planning are paramount to avoid costly mistakes. Secondly, time constraints are notable; the layup process itself is highly intensive and demands an uninterrupted block of time, requiring careful scheduling around other makerspace activities. Relatedly, limited workspace availability could complicate this planning. Additionally, the curing intervals for resins, finishes, and paints, typically requiring around 24 hours each, further strain the timeline. Lastly, materials pose a challenge; the slightly thicker-than-anticipated maple and cherry veneers will complicate achieving the exact shapes and contours envisioned. Overcoming this material limitation will involve additional precision during the shaping and cutting phases. Finally, by thoroughly researching techniques and meticulously managing each stage of production, I hope to navigate these constraints successfully and create a board that fully meets my high standards. Addressing these constraints with meticulous planning and execution will be essential to overcoming these challenges and achieving the high-quality, durable, and visually appealing deck I aspire to create!

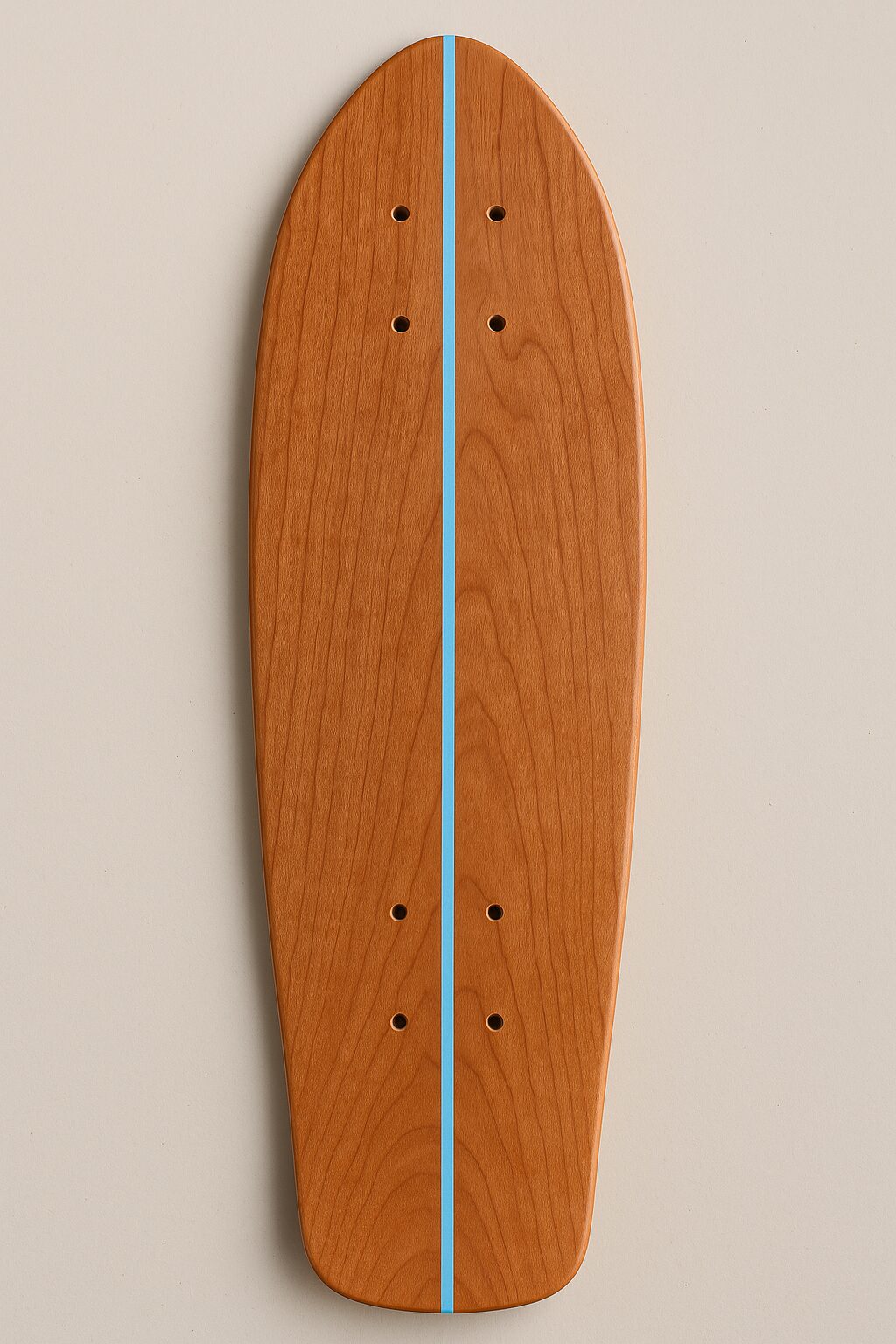

Cover photo GPT4o prompt “May you please generate an image of a cherry wood old school skate deck with a wide rear kick, thinner waist and with a pastel blue pinstripe going down the center.”

3 Comments. Leave new

Love how ChatGPT visualized the board. Planning and prepping for this project seem like a major part to achieve the desired outcome. By chance, do you have a contingency plan in case something does go wrong during the layup of the deck? Being prepared for the worst-case scenario may be a good idea here. I’m excited to see the progress in the coming weeks.

My contingency plan will be to reclaim some plywood from a previous project and follow the goals of this project with the manufacturing process I am more familiar with. I hadn’t actually developed a plan before your comment, thank you!

I am impressed with the image that GPT4o generated for your skate deck. That was a smart way of portraying your design, and I will use that idea for my future posts.

I did not realize how much time this would take. This is going to be a lot of hard work and I am excited to see the final product.