Introduction

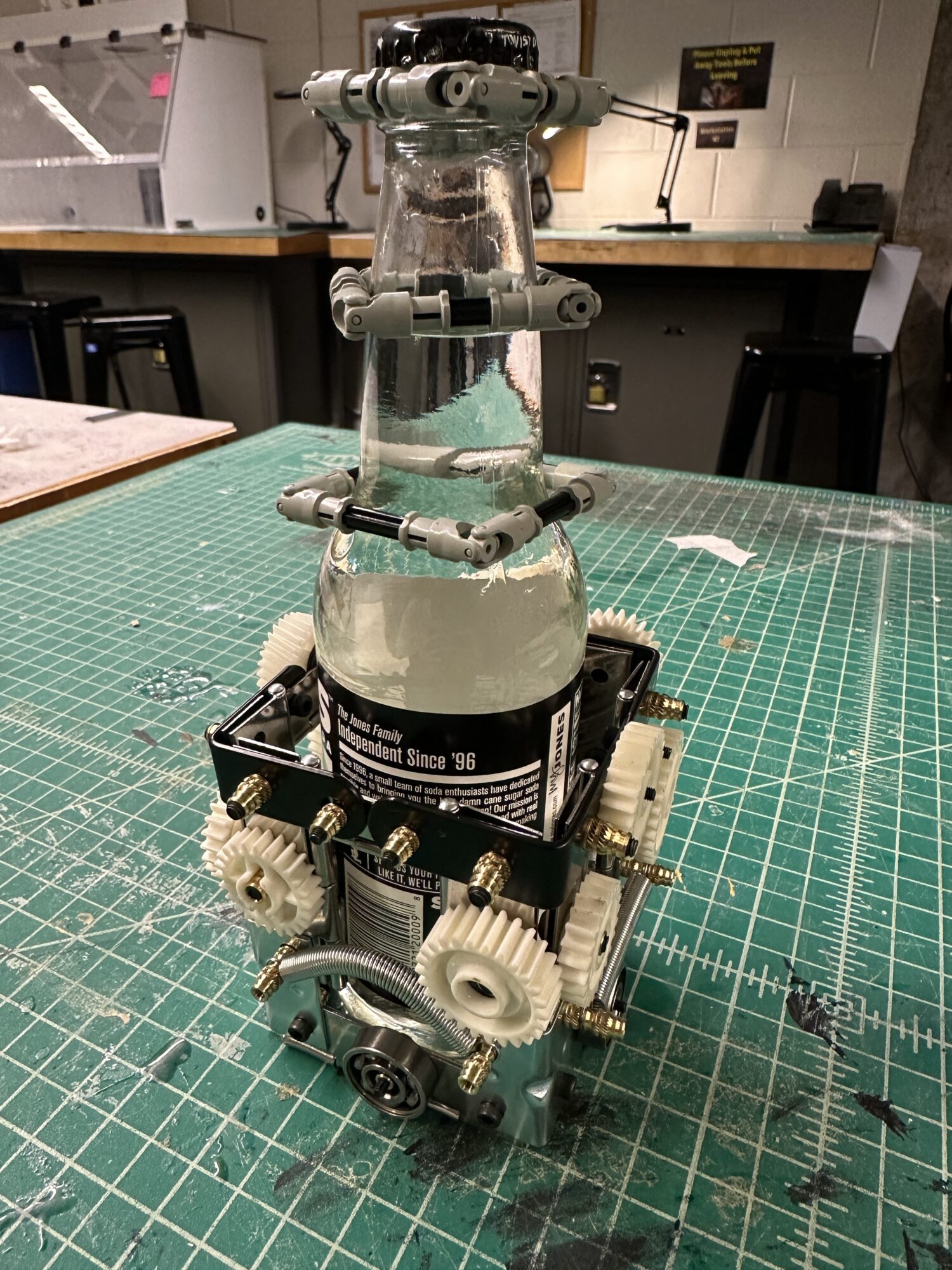

The upcycle project for this class has been an exciting and challenging task, requiring resourcefulness, creativity, and hands-on fabrication. The goal was to transform discarded materials into something functional and aesthetically compelling, demonstrating the potential of upcycling as a sustainable design approach. After collecting materials, and experimenting with different configurations, I have finally created something that I am happy with.

This post will provide an in-depth look at my work over the first third of the semester, including materials acquisition, design iterations, fabrication progress, challenges faced, and any updates or improvements I am looking to make in the future. Through this project, I aim to merge functionality with artistry, creating something that is both innovative and practical.

Materials Collection:

One of the most important early steps in the upcycling process is sourcing the right materials. Unlike traditional projects where materials are chosen based on pre-determined specifications, upcycling requires a unique approach allowing the available materials to help shape the design.

Where I Found My Materials

I gathered materials from a variety of sources, focusing on repurposing components that would otherwise go to waste, or sourcing things that I found for free:

-

The Project Depot in the Engineering Center

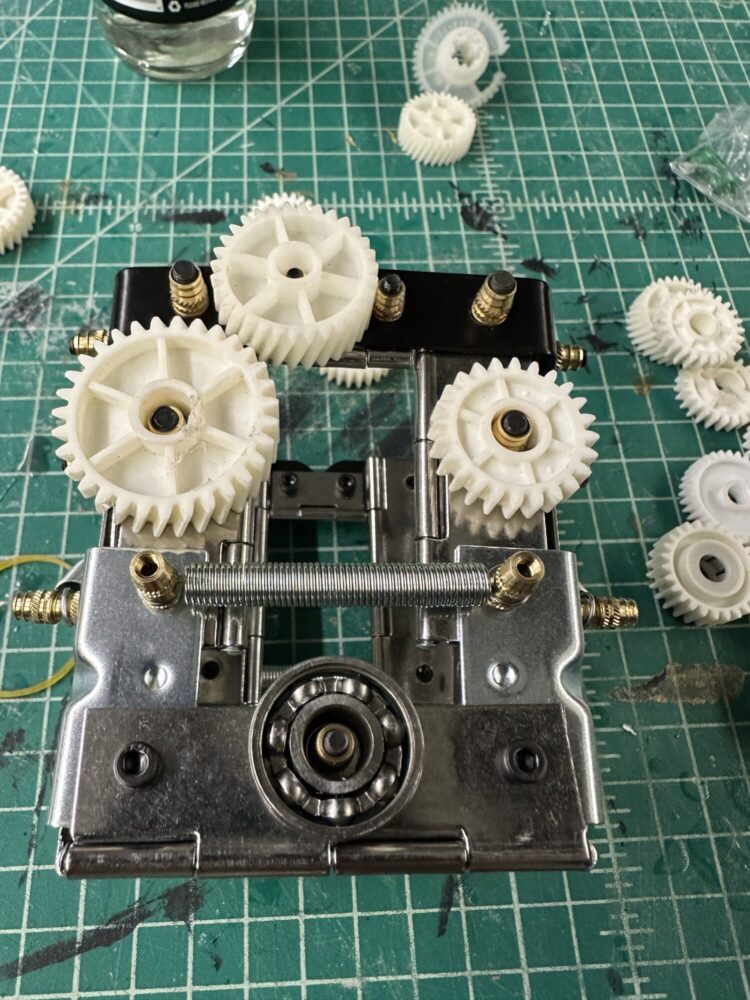

- The Project Depot is an excellent resource for leftover materials from past projects. I found a wide range of useful components, including fasteners, nuts, bearings, gears, and metal brackets.

-

The ITLL (Integrated Teaching and Learning Laboratory) Storage Room

- The ITLL contains a stockpile of materials from various engineering projects. This was a valuable source for metal parts, structural pieces, and other components that could be repurposed.

-

Miscellaneous Salvaged Items

- Beyond the Engineering Center and ITLL, I kept an eye out for discarded or surplus materials that could contribute to my project. I was on the lookout for anything shiny or futuristic looking, that could contribute to the vison in a creative way.

Inventory of Collected Materials

So far, my collection of materials includes the following items:

- Fasteners, Nuts, and Bolts – Essential for structural connections, ensuring that different parts are securely assembled.

- Bearings – Useful for allowing smooth rotational movement in any mechanical component. In my project these turned out to serve as a more aesthetic purpose then a functional one.

- Gears – Potentially crucial if my project incorporates motion or interactive elements.

- Beer Bottle – A unique element that adds the main structure to the design. Color choice of the bottle was an important aspect here too.

- Hinge Pieces (Various Sizes) – Allowing for movement and articulation in the final design.

- Springs – Could be incorporated for mechanical movement, energy absorption, or a dynamic function.

- Bracket Pieces – Providing reinforcement and structural stability.

Design Concept Development

With the materials in hand, I began brainstorming and sketching potential designs. Since upcycling requires adapting to available materials, my design process has been iterative, evolving as I test different configurations.

Early Design Considerations

At the start of the project, I envisioned creating something that incorporated movement, either through mechanical components or an interactive design. The combination of gears, bearings, and hinges offers several possibilities:

- A kinetic sculpture that moves when touched or powered by a simple mechanism.

- A functional device, such as a unique lamp, holder, or mechanical art piece.

- A decorative yet interactive piece, where movement or articulation enhances the design.

I sketched out multiple potential designs, experimenting with different ways to incorporate the beer bottle into the structure. My main challenge was determining how to integrate mechanical components in a way that enhances both form and function.

Fabrication Process:

Once I had a rough design in mind, I moved on to fabrication. Working with upcycled materials presents unique challenges and finding a way for them to all fit together was the biggest challenge.

Week 1: Initial Assembly and Testing

- Material Cleaning and Inspection

- Before assembly, I cleaned and inspected all collected materials to ensure they were in good condition. Some metal pieces had minor imperfections that required sanding or adjustment.

- Preliminary Assembly and Layout Testing

- I experimented with different configurations, arranging components in various ways to see what worked best. This helped me determine the ideal placement of gears, hinges, and fasteners.

- Structural Planning

- Since I’m working with a mix of metal, glass, and mechanical parts, I had to decide on the best joining techniques—whether bolting, glueing, or another joining technique. The outer housing has to accommodate the fragile glass bottle that sat on the inside of the piece.

Week 2: Structural Work and Mechanical Integration

- Cutting and Shaping Metal Parts

- Some brackets needed resizing, requiring cutting and sanding to achieve the correct dimensions. This was just due to them being slightly oversized.

- Fastening and Stability Testing

- I secured the initial structure using bolts and brackets, ensuring that the framework was stable before adding aesthetic elements.

Week 3: Refinements and Functional Testing

- Addressing Fitment Issues

- Some components didn’t align perfectly, so I adjusted the positioning of fasteners and hinges to improve movement and stability.

- Beer Bottle Integration

- Since glass is fragile, I explored different ways to mount the beer bottle without adding so much stress on any specific area. Some things I considered included using a supportive frame or securing it with a combination of soft materials and adhesives.

- Preliminary Testing

- I conducted stability and function tests to identify any weak points. I also looked on the inside to make sure there weren’t any elements that would put pressure onto the bottle.

- I conducted stability and function tests to identify any weak points. I also looked on the inside to make sure there weren’t any elements that would put pressure onto the bottle.

Challenges Encountered and Solutions Implemented

Challenge 1: Mismatched Component Sizes

- Problem: Some salvaged parts had different hole sizes or alignment issues.

- Solution: I drilled new holes where needed and used washers or spacers to adjust fitment.

Challenge 2: Structural Stability

- Problem: Some bracket connections were not strong enough.

- Solution: I reinforced weak points with additional brackets and ensured load-bearing connections were securely fastened.

Challenge 3: Integrating the Beer Bottle

- Problem: Glass can be difficult to work with and is prone to breakage.

- Solution: I explored different mounting techniques, ensuring glass did not come in contact with the rough metal interior.

Next Steps and Future Plans

Final Assembly

- Ensure all components are securely in place.

- Made sure there were no jagged edges to ensure the safety of my design.

Aesthetic and Functional Refinements

- Apply finishing touches, including polishing, and additional aesthetic elements.

- Improve any rough edges or exposed parts.

Presentation and Documentation

- Took high-quality images of the final product.

- Prepared design review presentation that documented my progress.

Conclusion

The upcycle project has been a rewarding and insightful journey, pushing me to think creatively while overcoming the challenges of working with salvaged materials. Through careful material selection, iterative design exploration, and hands-on fabrication, I have successfully transformed discarded components into a unique and functional piece. The process reinforced the importance of adaptability, problem-solving, and attention to detail, especially when integrating diverse materials like metal and glass. Moving forward, I will continue refining the design, ensuring both structural integrity and aesthetic appeal. This project has deepened my appreciation for upcycling as a sustainable design approach, and I am excited to apply these skills to future creative endeavors.

2 Comments. Leave new

The iterative design process you described reflects a thoughtful engagement with the materials at hand. I appreciated how you allowed the available components to guide your design direction instead than forcing a predetermined concept. Could you share some of your initial sketches or photos of early prototypes? Seeing the progression from concept to finished piece would help readers better understand your creative process and the challenges you overcame along the way.

t’s really cool to see this project come full circle from concept to completion! The combination of salvaged metal and glass creates a unique, futuristic look, and your problem-solving with stability and fitment really paid off. This is an impressive upcycle with a lot of creative problem solving!