This will be written as if I were still at this point in the semester!

My upcycle project was going very smoothly – I had created an initial design in CAD and started sourcing materials from around the ITLL.

Materials Sourcing

I spread the word among my coworkers to save any empty spools when a printer would run out, rather than immediately recycling spools. Before I knew it, I had a large stack of 25+ spools – more than I needed to complete the project. I also sourced a large sheet of scrap material from the ITLL machine shop, which was then cut to size and painted to fit the size & aesthetic goals for this shelving unit.

Individual Shelf Unit Design

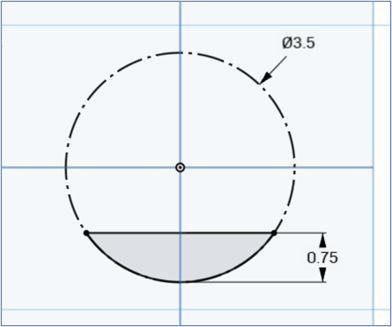

The primary “shell” of each shelf is made up of the existing inner diameter of each 3DP filament spool, chosen for its already round shape and rigid structure! Each has an Inner Diameter of 3.5 inches. This is small, but allows for the shelving units to be arranged into different shapes… and still is big enough to display some example 3D prints with!

The inner shelving units are laser cut from the outer rings of the 3DP filament spool. Two rounded pieces of 0.75” tall fit to the inner diameter of the spool at the front/back edges, and a 2.872” x 2.25” square is placed on top as the flat surface for example prints. After much trial and error (and a few incinerated cardboard rings), I finally had dialed the laser cutter settings in – sometimes requiring an x-acto knife to push all the way through, but overall getting consistent, clean cuts each time. Hot Glue was used to piece these four elements together.

Overall Design:

As this piece will be hung up in the ITLL makerspace on campus and is intended as a way to give back to a program which has given me so much, I aimed to arrange the shelving units in the shape of the program logo!

The initial design was intended to match the pop industrial aesthetic of the ITLL as a whole, using a gloss white paint for the cardboard shelves to make the lettering pop, and a light bar around the exterior of the lettering to match the pops of color found throughout the building (and especially the 3D printers). The multicolor light-bar also incorporates some elements of Spacecore, providing a “starry” sparkle against the deep blue blackground of the old ITLL logo. This was intended to be a matte navy, allowing for the lettering and prints to become the focal points of the piece.

The 16-unit design was chosen to fill the chosen space where this piece will be hung up: a 30” x 30” square space above the water fountain by the 3D printers. The piece itself will be 28” x 28” to allow for the piece to fit cleanly into the space, and the lettering itself will occupy 22” x 22” of that space.

2 Comments. Leave new

Your overall design concept is thoughtful – arranging the shelves to form the ITLL logo creates a meaningful connection to the space where it will be displayed. The aesthetic choices align well with the environment: gloss white shelves to make the lettering pop, a light bar for visual interest, and the deep blue background to make the elements stand out.

This is a really creative way to repurpose filament spools while also giving back to the ITLL community. The integration of the program’s logo into the shelving design is a great touch, and the pop industrial aesthetic fits the space well. Did you run into any challenges when assembling the shelving units into the final arrangement?