My main inspiration for this project is the gyroscopic watch winder I saw online. The watch winder is made by a YouTuber named Practical Engineer. While looking for watch winders online, I realized I might be able to make one. After talking to my friend, who did it alone, I realized I could make one independently. After this, I began researching different styles and aesthetics reasonable for DIY. After researching for a while, I came across the gyroscopic watch winder and realized that it followed the aesthetics I wanted and had a lot of step-by-step instructions. I plan on using a design like the one used in the gyroscopic design created by a Practical Engineer. But it will likely be modified to use different materials. While the plans for the winder are available online for purchase, I will try to create my plans for it.

Picture 1: Gyroscopic Watch from Practical Engineer

Picture 1: Gyroscopic Watch from Practical Engineer

The mechanism I plan to use to drive the watch winder will be based on another design I found online. The design I found online is another gyroscopic watch winder that someone fabricated. This one, however, is made using 3D printing, an Arduino Nano, and a wall plugin, which I wanted for my design. This video helped as inspiration because it showed a creative and innovative way to drive the rotation using a stepper motor and electrical materials that I can access through the ITLL. This inspiration does not closely follow the mid-century modern aesthetic as the one above, but it gives me an excellent resource for how I should be doing the electrical work.

Picture 2: Another Gyroscopic Watch Winder

Picture 2: Another Gyroscopic Watch Winder

My vision for the project is a watch winder that includes an organic movement inspired by a gyroscope or things of a similar nature. Its function is to hold my automatic watch successfully, rotate it, and wind the spring inside to keep it on longer and ready for use when I put it on. Its form should be like a gyroscope, with a lot of round organic geometry. This will give the watch a mid-century modern aesthetic and replicate the aesthetic. My artistic vision includes clean materials, either wood or plastic, that are smooth and possibly painted to give a warm vibe like many mid-century modern decorations.

Along with my vision for the aesthetic, there will be a lot of parts necessary to ensure the functionality of the watch winder. As referenced above, the primary mechanism driving the watch winder will be based on the YouTube video linked at the bottom of the post. The parts will consist of:

Plywood and fasteners—I plan to create the box using some type of plywood and fasteners. This will allow me to keep a mid-century modern aesthetic in terms of material and make the winder relatively cheap. It will also be easy to laser cut plywood to the geometries I want to use for this project.

Arduino Nano—The Arduino Nano is a microcontroller that will be programmed to run the watch winder. Its small form factor makes it easy to include and hide within the build. The Arduino Nano also allows for easy control of the motor, such as reversing directions, different speeds for the watch’s revolutions, and the ability to have a timer for the amount the watch is moving.

Jumper cables and heat shrink—All jumper cables and electrical connections will be made using cables from the ITLL. By using materials from the ITLL, I will save money and have access to high-quality components that will ensure the safety of the build. Heat shrink will also provide a stable electrical connection and a good solder connection while insulating the electrical signals.

Push Button Switch—The push button switch turns the watch winder on and off. It helps ensure that the device only gets power when necessary, making it safer and saving me money on the electricity bill.

Motor—I currently have a small stepper motor that will drive the mechanism. The motor is essential because how smoothly it moves and whether it can move quickly or slowly determines the project’s functionality.

Power Jack—I will purchase a power jack to ensure a steady delivery of 5V to my watch winder. By plugging it into the wall and having an AC-to-DC converter, I will also provide a safe and stable electric current to ensure no electrical complications within the project.

Alternate Design Aesthetic – Modern:

An alternate aesthetic for the design that I have considered is modern. I would communicate the modern aesthetic by using different and more metallic materials. The picture below shows this aesthetic:

Picture 3: A Modern Aesthetic Watch Winder

Picture 3: A Modern Aesthetic Watch Winder

The watch winder here uses modern materials in a grey futuristic color scheme. While this design initially intrigued me, I was intimidated by the idea of having to machine metal to complete it. Because of that, I opted for a mid-century modern aesthetic that would allow for a broader range of materials and more freedom of form.

Alternate Aesthetic – Luxury:

Finally, I considered following a luxury aesthetic. The luxury aesthetic usually makes use of elegant designs with high-end materials. One example of a luxury watch winder is shown in the picture below:

Picture 4: Luxury Aesthetic Watch Winder

Picture 4: Luxury Aesthetic Watch Winder

The luxury aesthetic originally was something I considered because of the nature of watches. Although I own cheaper watches, the watchmaking and timepiece industry is often considered a luxury. So, a luxury watch winder would follow this theme. After considering this, I realized that I did not have the resources to make a luxury box. It would likely require soft clothes and polished wood, but I do not have the time or the money to create a product like that. Because of this, I favored modern or mid-century modern more.

I sourced the alternate aesthetic descriptions from my previous post. The alternate aesthetics gave me some more perspective on how I could use materials differently and how I should distinguish between aesthetics for the watch winder. Because of their purpose, watch winders are often associated with luxury, and watches are considered luxury goods. So, I must emphasize warm colors and unique geometries specific to mid-century modern aesthetics. Overall, the alternate aesthetics did not change my plans for the watch, but they gave me ideas on differentiating the aesthetics more effectively.

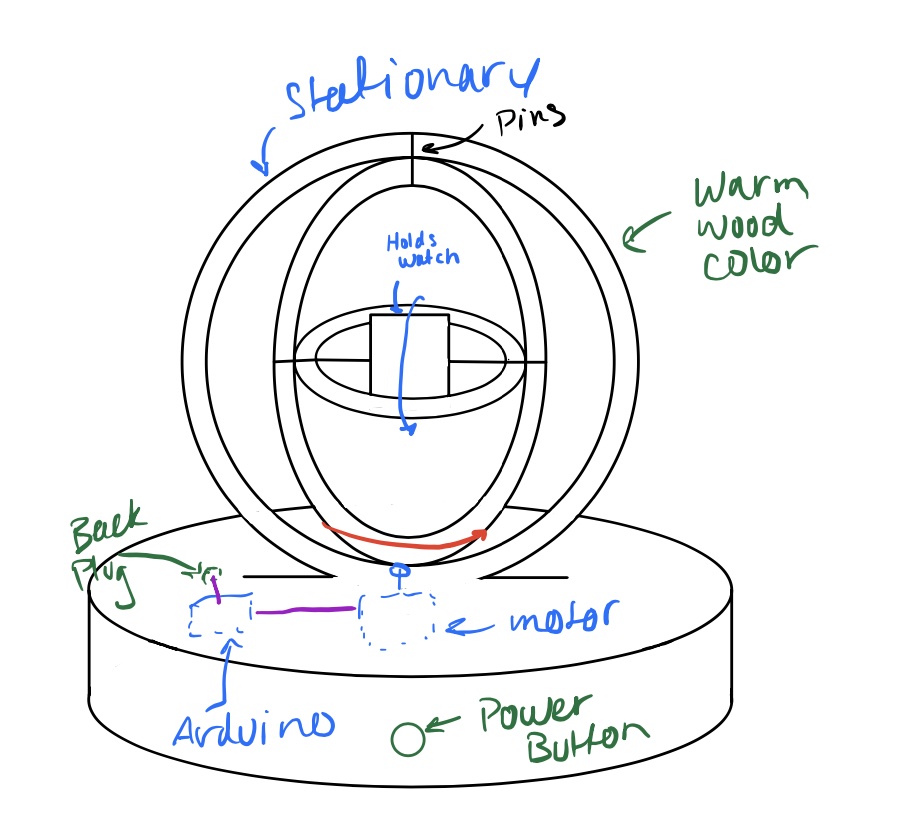

I have not yet completed any CAD drawings for the design plan, but I will include my initial sketch below. The sketch shows a rough idea of how the project started being conceptualized and general notes on how I will keep the aesthetic.

Picture 5: Initial Project Sketch

While I have not finished any prototyping or fabrication, I have developed a timeline for the project with overarching deliverables/action items.

This timeline includes significant project deliverables regarding the project’s creation and fabrication. Many smaller action items will be added in subsections of this schedule, but to make the reading more manageable, I kept it to the significant, over-arching goals and deadlines.

The product will be made primarily with laser cutting as of right now. The steps include creating CAD drawings of all parts, importing them as DXF parts, and using CorelDraw in the ITLL to create files that can be used on the laser cutter. After these parts are laser cut, I will likely use wood glue and clamps to hold them together and create solid pieces. After the pieces are made, a lot of assembly will be included to put them into an actual form that will be functional. In addition to wood manufacturing and fabrication, there will also be light electrical work. The electrical work will mainly take place in the assembly phase. There will be some soldering that will be necessary for the components to maintain a good connection. Finally, there will also be a very brief coding part of the project. The code is already online, so it will be more of an upload to Arduino to ensure it works. I have used all of the skills necessary for this project before. While I will increase my ability and improve my skills, I will not learn anything new during this project.

Feature Image: https://www.watches.com/products/mainspring-astronomy-gyroscope-watch-winder-silver-mercury-ms-win-gyr1-05

Picture 1: https://thepracticalengineer.com/blog/watchwinder

Picture 2: https://cults3d.com/en/3d-model/fashion/gyro-winder-watch-winder-remontoir-montre

Picture 3: https://www.mozsly.com/products/mozsly%C2%AE-double-watch-winder-grey-leather

Picture 4: https://www.amazon.com/Flexible-Pillows-Featured-Pattern-Included/dp/B08NVZNWXG

Picture 5: Drawn by myself

7 Comments. Leave new

You do a great job outlining both your inspiration and how you adapted the project to fit your materials and skills. Could you explain more about how you plan to ensure the smooth, organic movement of the gyroscope with the stepper motor you have?

Hi Garrison,

As a big watch nerd, this project really speaks to me. Your detailed breakdown of aesthetics, materials, and mechanics is super well thought out, and I love how you’re customizing the design instead of just following a pre-made template. Thanks for the inspiration, I am definitely adding this to my list of future builds. Excited to see how yours turns out!

Hello Robert,

Thanks for the kind words, I always love seeing another person passionate about watches. I honestly was thinking of following the videos step by step, but I am glad that you think the decision to do my own thing is a good one. Thanks, have a good one!

Hi Garrison,

Really cool project! I’ve seen online how expensive a good watch winder can be, and I find your plan to make your own impressive. I’m looking forward to seeing a CAD model of your design. It would also be great to see a video demonstrating how it is supposed to work. Do the multiple axes of rotation change how the watch is wound, or is it just as effective as the classic ones that rotate in one direction?

Hello Clemens,

The price of watch winders online was actually a huge factor when deciding to make my own. The CAD model is coming along okay but definitely has some more that needs to be done. If you are interested you can check the youtube videos I linked to see how the pre-existing ones work, but I will consider making a video after it is completed for the post. The multiple axis of rotation do not have a huge effect on how the watch is wound, but it definitely looks cooler!

Hi Garrison,

I love this idea, I’ve never seen anything like this before and I think its a unique way to display a watch versus just the standard watch case. You mentioned you will laser cut out the wood will you be adding a finish as well? I think it could really elevate the design. I’m interested to see how this will turn out!

Hello Mila,

Thank you for the kind words about the idea. I probably will be adding a finish to the wood. I believe it will help to make the design look a lot better and more professional.