For my main project, I am converting a 1907 Waltham Grade 165 (~0s, 15J) pocket watch movement into a wearable wristwatch. I chose this movement because, as a 0s movement, it has a modest 29mm diameter, making it well-suited for wristwatch conversion without looking overly large like many pocket watch conversions that use 16s or 18s railroad-grade movements. Historically, the 0s movement was primarily used in women’s watches due to its compact size, which further supports its suitability for wristwear.

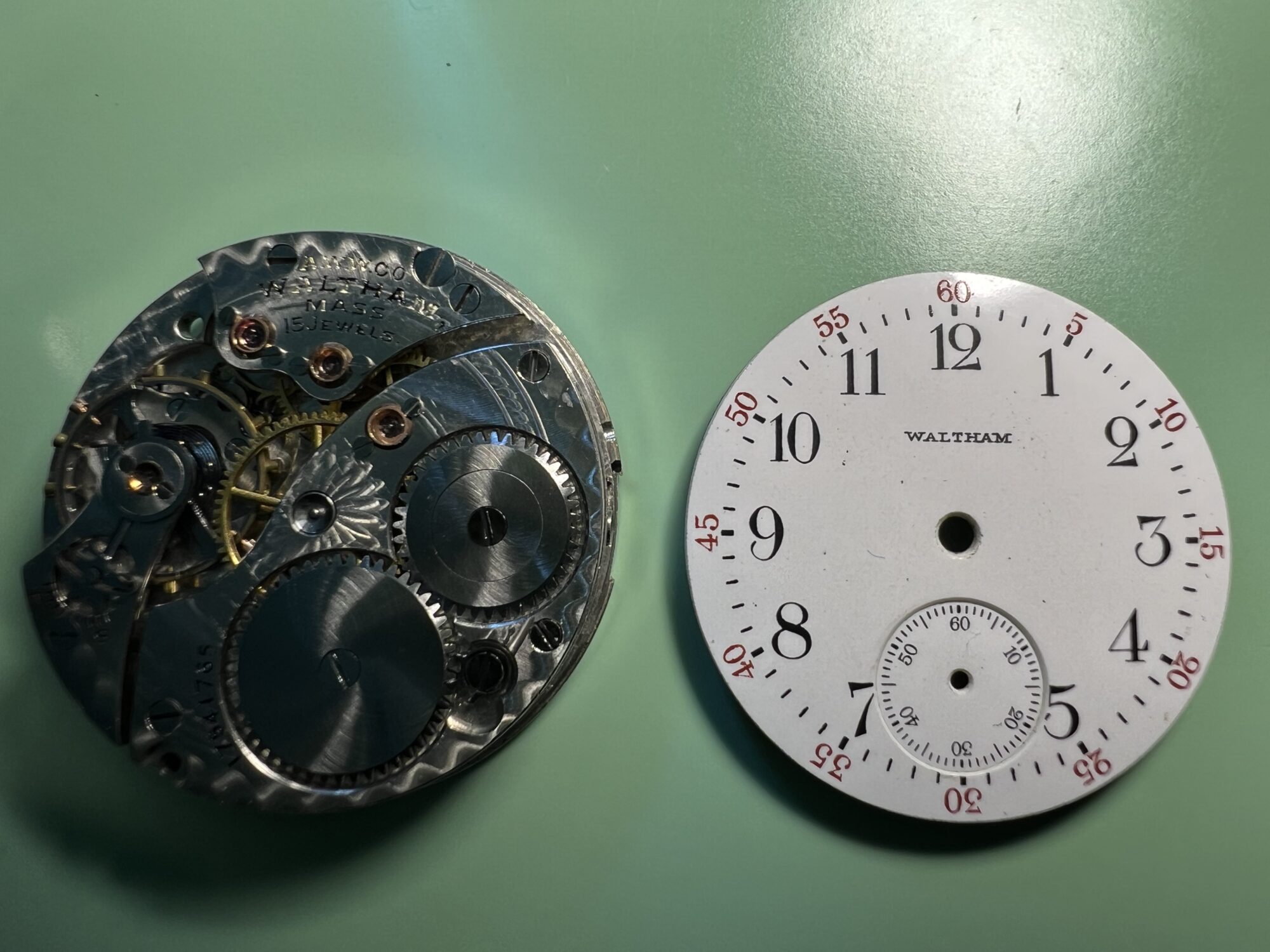

Beyond its proportions, this movement shares nearly identical dimensions to the NH35 and ETA 2824, two of the most common automatic watch movements today. This opens up many possibilities for using aftermarket watch cases. I have sourced several NH35 and ETA 2824-compatible cases to experiment with machining and fitting. These cases also include waterproofing options, which is a great way to modernize the watch and improve its practicality for daily wear. Additionally, they feature glass exhibition casebacks, which is an essential part of my project. One of my main goals is to showcase the exquisite craftsmanship and ornamentation of these early 20th-century movements. The Waltham movement is entirely hand-machined and engraved, a level of detail that is rarely seen in modern watchmaking.

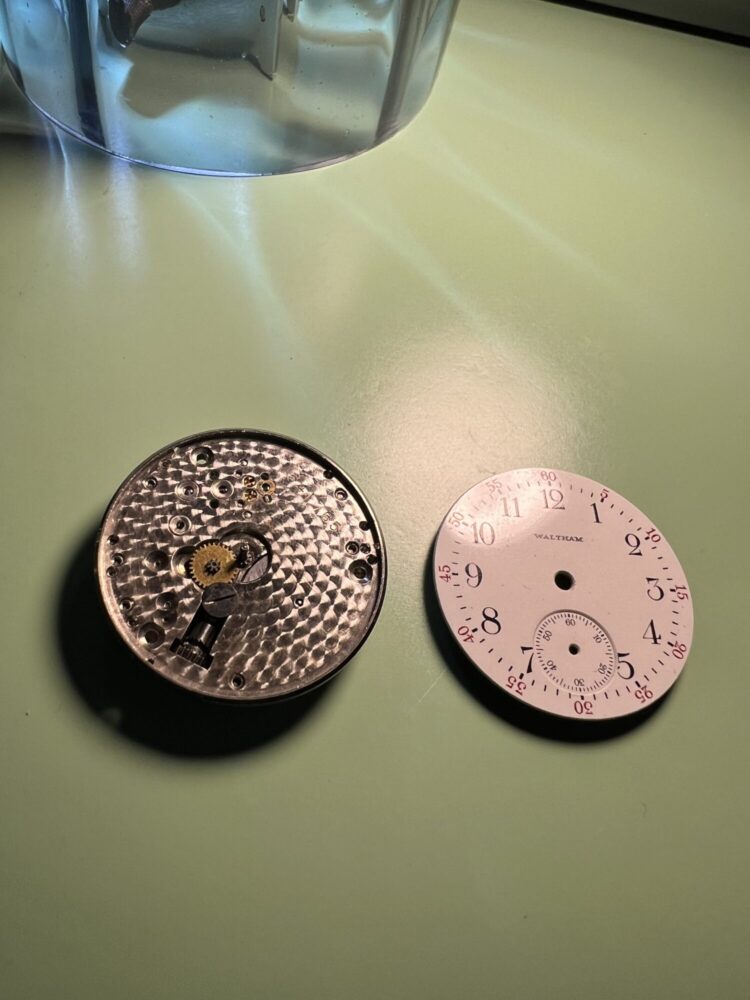

This movement comes from an era before modernist industrialization, a time when beauty was incorporated into nearly every product. This aesthetic is something I deeply admire and want to revive in a functional way. The enamel dial is another key feature of this movement. Enamel dials, once a standard in fine watchmaking, are now a lost art, appearing only in the highest-end luxury watches. Preserving this detail adds to the project’s significance.

A major challenge in this conversion is adapting the winding mechanism. Unlike modern pull-to-set stems, this movement uses a pendant-set system, which requires a different approach. Instead of the winding stem being sized to the movement, it was originally sized to the case and secured with a special stem sleeve. I sourced a 120 year old set of new old stock (NOS) pendant-set stem sleeves from eBay, which was difficult to find and will require trial and error to determine compatibility. Fortunately, I discovered that the ETA 2824 stem fits the Waltham movement, which is a significant breakthrough. This means I can use an off-the-shelf ETA 2824 case without modifying the screw down crown, simplifying the conversion process.

Initially, I planned to design and machine a custom watch case, but I ultimately abandoned the idea due to the ITLL’s CNC restrictions on steel and the difficulty of securing a time slot. Instead, modifying an existing case provides a more realistic and efficient solution.

I have fully serviced the movement, ensuring it runs accurately and is ready for installation. The next challenge will be machining the inner diameter of the watch case, as it is fractions of a millimeter too small to accommodate the movement. Additionally, I will need to cut and tap the stem to fit the pendant-set sleeve properly. These final machining steps will be crucial in ensuring the functionality and reliability of the completed wristwatch.

2 Comments. Leave new

Hi – I am excited to see the result of your project! Like Zoe said, you definitely have the knowledge of watch-craft and I like that you’re upcycling, too. The picture of the movement top view really helps to highlight the exquisite hand-crafted detail that you hope to preserve through your watch conversion. Have you given thought to the type of wristband you want to complete the watch?

Wow, you know a lot about watches! I’ll be honest, a lot of the things you mentioned in this post, I have no idea about. However, it’s clear that you have the knowledge needed to complete this project, so I commend you for that. It seems like it will be meticulous, but the final project is a really cool idea. The thing I like the most is taking an old pocket watch, which may not have much practical purpose modern-day besides for collectors and repurposing it to possibly wear yourself as a bit of an art piece. I hope the machinery works smooth in the end!