For my main project, I decided to design and manufacture the front suspension uprights for my 1965 Ford Mustang race car project. The aesthetic that I have decided on for this project is an aerospace aesthetic. This aesthetic consists of streamlined shapes and smooth radiused edges. The designs featuring this aesthetic often showcase geometric patterns such as triangles and grids which are often associated with the design of spacecrafts and airplanes for improved strength to weight ratios of components. Additionally, the aesthetic incorporates a minimalist approach involving clean lines and features that mainly aid towards the proper function of the design. The materials chosen to illustrate this aesthetic are often state of the art and advanced for the time. For this project, I have chosen to manufacture the uprights from 7075-T651 aluminum due to the high strength and lightweight characteristics of the material. Any components of this design that are not made from aluminum shall be made from 4140 chromoly steel as this material is high strength and corrosion resistant.

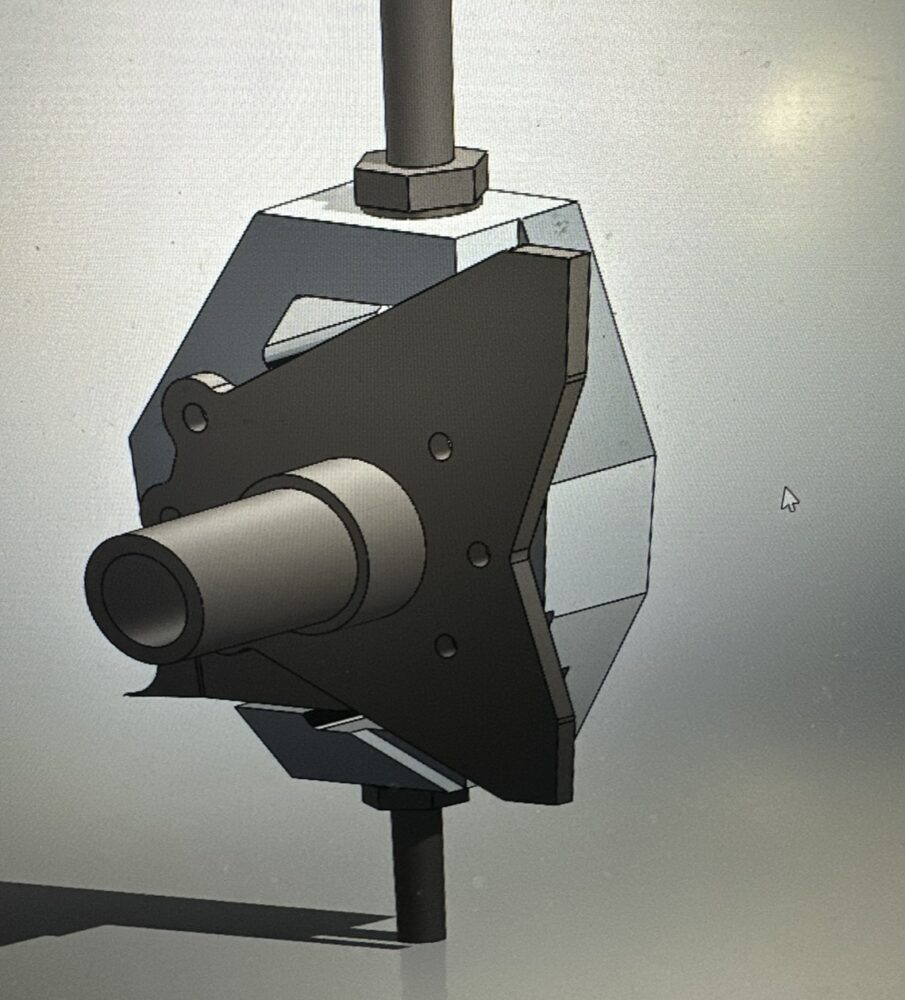

The image shown below illustrates an initial model of the upright designed with the aerospace aesthetic in mind. Notice that the smooth radiused edges and the triangular shaped pocketing within the upright to reduce the overall weight of the assembly while maintaining the required strength with the selected manufacturing materials to avoid failure. The next step of the design process is to model a spindle pin in which the wheel hub will interface to the upright. To accomplish this, I will need to use my established wheel mounting hub dimensions to establish my bearing clearances and vehicle scrub radius which is critical to the geometry of the front suspension. Additionally, I will need to finalize my brake caliper mounting interface.

An alternative aesthetic to the aerospace aesthetic would be a strictly utilitarian aesthetic. This aesthetic incorporates a design that is simplified and more easily manufacturable. Removing the radiused edges and complex geometric patterns allows for simplified tool paths using a milling machine and a quicker run time to manufacture the parts. It is also bulkier and less refined and as a result I can use materials that are less expensive and lower in strength in order to maintain the same overall functionality of the design.

The image shown below illustrates a model of the upright designed using a utilitarian aesthetic. This model was designed in SolidWorks and illustrates the simplified spindle pin which interfaces with the wheel hub. Notice the sharp machine lines and the lack on pocketing to reduce the weight of the design. This utilitarian design would incorporate a mild steel spindle pin and 6061-T6 aluminum upright material which are less expensive than the chosen materials for my aerospace aesthetic.

2 Comments. Leave new

Your 1965 Mustang suspension upright design is awesome! The aerospace aesthetic with smooth curves, lightweight pocketing, and high-strength materials makes it both functional and sleek. Using 7075 aluminum and 4140 steel keeps it strong yet lightweight. The utilitarian version is simpler and cheaper but loses the refined engineering of your aerospace design. Your approach balances performance and aesthetics perfectly! Have you considered anodizing the aluminum for added durability and corrosion resistance? Excited to see the final result!

Hello Jacob, thank you for the comments. I agree that the utilitarian design removes many of the defining qualities that make this design unique and performance oriented. I think that anodizing the aluminum would be a great feature to finish off the design. If I have any extra budget available after the purchasing of materials, then I will look into the possible anodizing service.