In this post, I discuss the aesthetic of fabricated sheet metal components. Sheet metal structures are often presented in aspects of architecture, furniture design, industrial machinery, and art sculptures. However, I will mainly focus on the aesthetic of sheet metal in the design of race cars. In the past, I worked in automotive fabrication and was frequently faced with designing sheet metal assemblies that had to satisfy a commonly accepted aesthetic of the industry.

Some critical aspects surrounding the aesthetic of fabricated sheet metal components include well defined edges and crisp bends. These key features often lead to a minimalistic and modern looking aesthetic. Where necessary, compound bends can be used where sheet metal geometry is complex, and the metal is often intentionally shrunk or stretched at one side of a bend line to avoid warping the thin metal and giving a smooth continuous radius on bends that appeals to the viewer.

To add to the aesthetic, a fabricator will often apply a surface finish to sheet metal components. Common choices of surface finish include leaving the surface raw, a high shine polish, textured, or brushed finish.

Maintaining symmetry and familiar geometric shapes is another aspect of sheet metal working that adds to the aesthetic. Making parts with rectangular, triangular, or square faces are often appealing to the viewer and aesthetically pleasing. Additionally, these components will often incorporate soft, radiused edges which give a more natural look to components and allow for the edge of one sheet metal component to transition nicely with the interface or overlap of another component.

Another complement to the aesthetic of crafted sheet metal components is the use of patterns and stamped shapes on the faces of sheet metal. These patterns serve a purpose to not only be appealing to the eye but also aid to the performance of the part during its lifetime. Bead rolling sheet metal is a way of stretching thin metal between dies and adding grooved patterns to the sheet metal which also strengthens the panel. Additionally, bead rolling can be used to flange the edges of sheet metal and allow for panels to sit flush with each other. Dimple dies are another specialized tool and provide a way to strengthen a sheet metal panel that offers a nice aesthetic pattern while strengthening and reducing the weight of a panel. Both increasing strength and decreasing the weight of these panels are desired when constructing a nimble racecar.

The image shown below is of a metal shrinker stretcher. This is a common tool used by a sheet metal worker to form compound curve geometry.

This image shown below is an example of a sheet metal door panel from a car with patterning made using a bead roller to stretch the metal into shape.

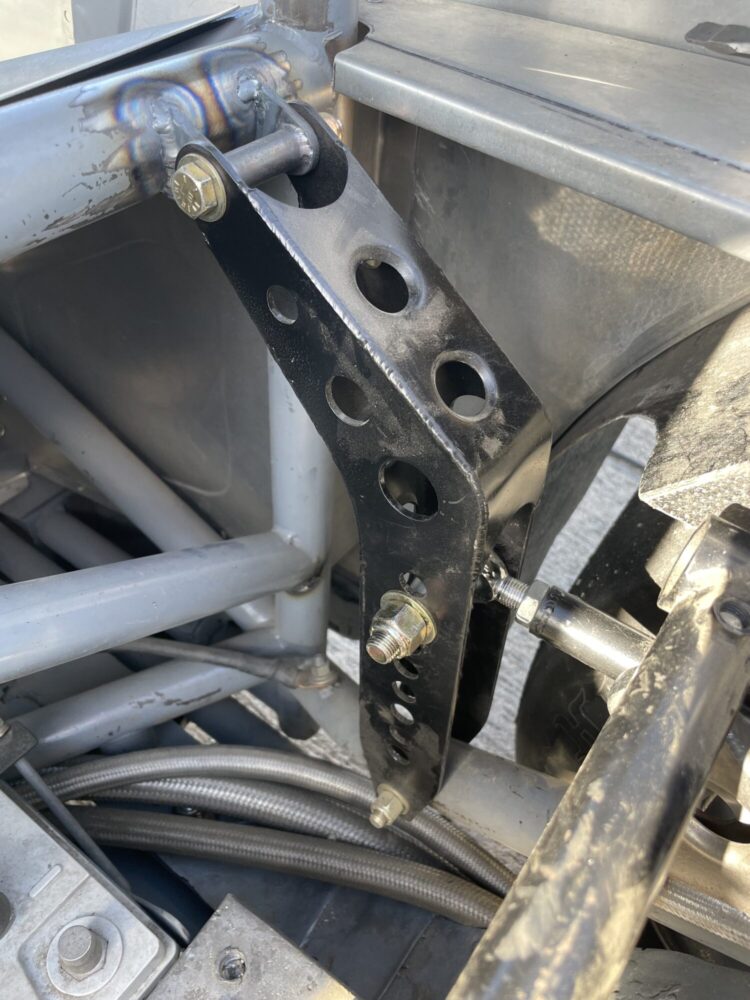

The image shown below illustrates a brake caliper floater bracket that has been fabricated out of sheet metal by me. The dimple died holes on the top of the component were added to aid in the aesthetic of the component and increase the strength.

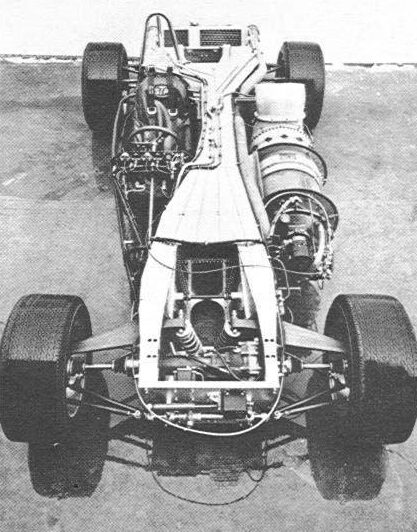

The image shown below is of the STP-Paxton Turbo Car. This car was built for the 1967 Indianapolis 500 Race and constructed out of a lightweight sheet metal monocoque. The panels were each painstakingly made by hand using known metal working methods of the time and riveted together to be strong enough to withstand the torsion from racing conditions, yet lightweight and offering a pleasing aesthetic.

The image below shows a fabricated firewall from a car made of sheet metal. The intricate patterns were created using a bead roller to create the deep grooves and an English wheel to stretch the panel flat again.

The image shown below illustrates the sheet metal paneling of a rear bulkhead on a race car. Bead rolled patterns were added to the panels to increase the rigidity as well as add a pleasing aesthetic. Additionally, the sections of sheet metal are overlapped and flanged to make the interfaces between components more subtle.

Works Cited

“Bead Rolled Firewall – 47-54 GMC Chevy Truck.” LS Fabrication, 27 Jan. 2025, lsfab.com/47-54-gmc-chevy-truck-parts/47-54-chevy-truck-firewall/.

“Electric Bead Roller – MBR-610XT.” Metal Man Tools, 25 Aug. 2024, metalmantools.com.au/product/electric-bead-roller-610mm-throat/.

Quiniou., Louis. “STP_PAXTON_TURBOCAR_GENERAL_VIEW.” Historic Motor Sport Central., 17 Oct. 2016, historicmotorsportcentral.com/2016/10/18/turbinetuesday-the-1967-stp-paxton-turbocar/ff2507a0a55a21e55606aefdb71ad01b/.

4 Comments. Leave new

I love how you talk about the craft of design for sheet metal in tandem with the aesthetics of it. Surface finish, clean bend lines, and texturing processes really do impact the aesthetics of a sheet metal piece. Having disassembled a car myself, there are so many hidden layers of sheet metal inside that most will never see, so it’s cool to see the work of automotive fabrication in its pristine state.

I am curious to learn more about the geometric specifics of this aesthetic though. What is the interplay between rectangular and triangular faces with some of the more organic geometry in your images? Would you consider the sheet metal exterior of modern cars as a different aesthetic?

I greatly enjoyed reading your feedback. When disassembling the interior of a car, it is amazing to see the layers of complex sheet metal patterns making up the superstructure. I think that the organic geometry is used to add a soft, more natural, touch to the interior geometric shapes which adds to the total appeal of the pattern. I would consider the exterior of cars to have the same aesthetic of sheet metal with a different application. Many of the same characteristics of sheet metal forming exist for external features such as crisp lines and compound bends of paneling.

The use of your own work for this post is awesome. In regards to the door panel, I’m assuming there is fabric that goes over that? It would be cool to see the final product along with some of these parts in fully assembled cars. This process looks very timing consuming and you did an amazing job on these pieces. How long did these panels take? Also, it would be cool to see the machines you used as well.

I greatly enjoyed reading your comments. Generally, bead rolled door panels are left as raw aluminum or steel within the car and aren’t covered by fabric. I edited the post to feature a picture of a metal shrinker stretcher which is a common tool used in sheet metal forming. The picture of the door panel was not created by me. However, I am responsible for a few of the other components such as the ignition box mounting tray which took roughly 8 hours of work to complete. Thank you for the constructive comments!