Overview:

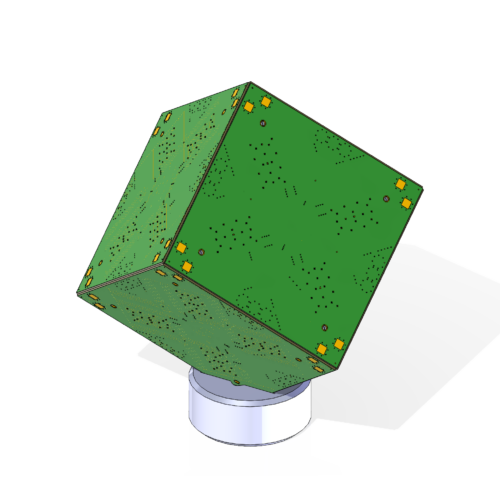

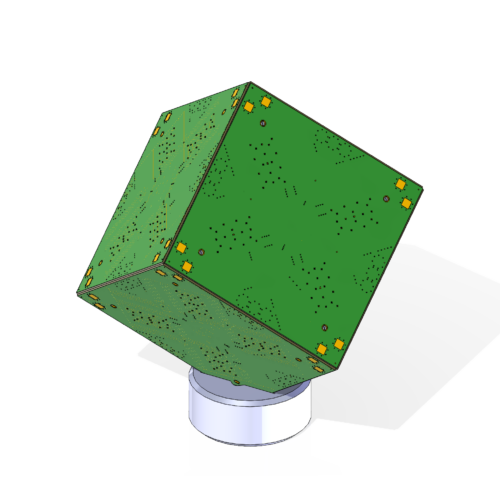

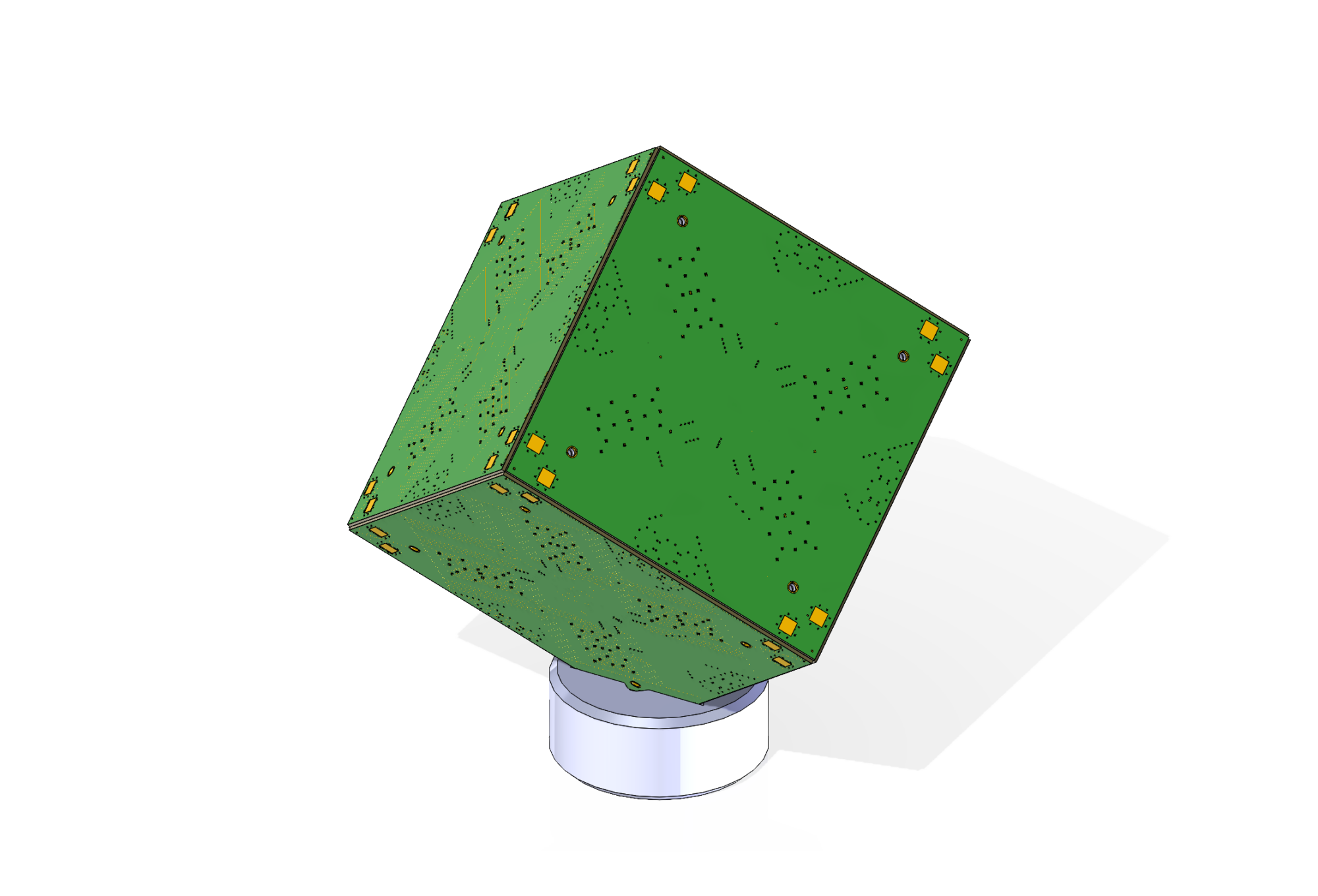

From my previous posts I am designing a PCB lamp with a CAD model shown below:

Since my design preview report, I have made significant progress on the design and project as a whole.. From my previous posts, my main goal was to submit the PCBs

Timeline Update:

Unfortunately, the timeline has been delayed slightly. In addition to spring break, I ended up missing the week after spring break as well due to competing at National College Disc Golf Championships. This extra school missed delayed the schedule slightly, however, I was able to send out the design to JLCPCB in order to receive them by they time I returned. Other than the extra school missed, I managed to stay on track with the project.

Scope Update:

As I mentioned in the specification post, the electronics may prove to be a bit of a challenge. At this point, I have decided that integrating battery power safely, as well as many of the other electronics is not worth the risk and time to do it safely. This should be the only aspect of the project which gets a change. The rest of the specifications should be reachable and allow for successful completion of the project.

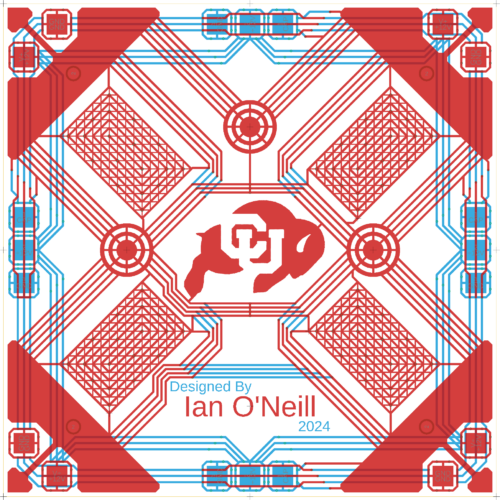

Progress: PCB Files

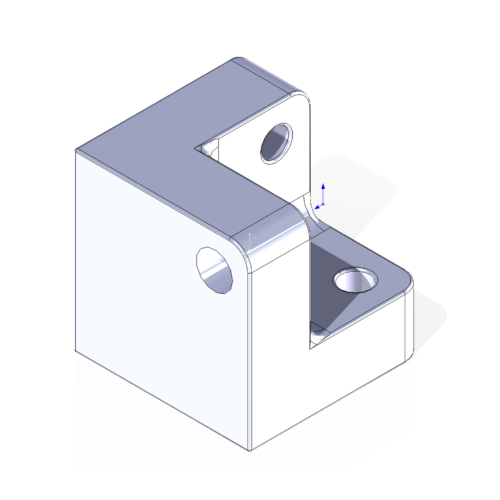

To have ordered the PCBs, I used the PCB footprint above shown in red and blue. Additionally, the order of PCBs came in which allows me to slowly begin assembling. The corner brackets are still in progress – the 3D printers have actually been giving me a lot of trouble recently.

Progress: CAD

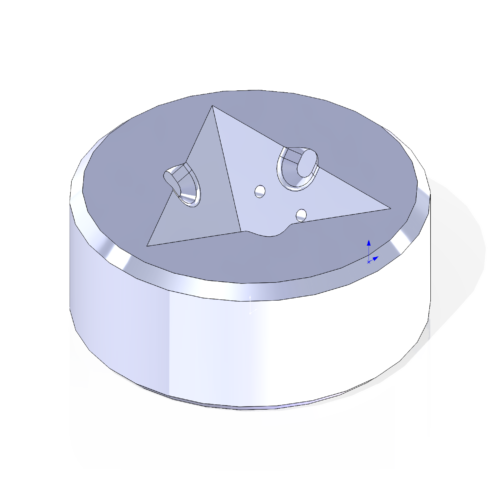

Most of the CAD was relatively easy. Built into Fusion 360 electronics is a button which converts the PCB into a step file. I utilized this in order to quickly create a CAD model for the lamp. Additionally, I was able to copy a design from a previous class for the corner brackets, it only required slight modification to the sizing to work properly.

The following three images depict the individual and final components Overall, the CAD looks great and I expect to receive good results from the 3D printers, staff, and JLCPCB.

Progress: Parts Acquisition

At this point, I have fully decided upon the components and am in the process of acquiring them. The PCBs took slightly longer than expected, however, they did arrive fully in tact and at high quality. In addition to the PCBs, I ordered the LED, started planning the wiring selection, and am working on printing out the rest of the components.

Conclusion

Overall, this project is making great progress. I expect it should be completed well before expo and ready to demo!

2 Comments. Leave new

Hey Ian! I really like the idea of your lamp being made out of PCBs, its really cool. I wonder what other shapes you could have made this lamp into?

Hi Ian!

What a great idea this PCB lamp. If I could ask you one question, it would be about different shape potential. Do you think this project would be much more difficult if you utilized a triangular shape?