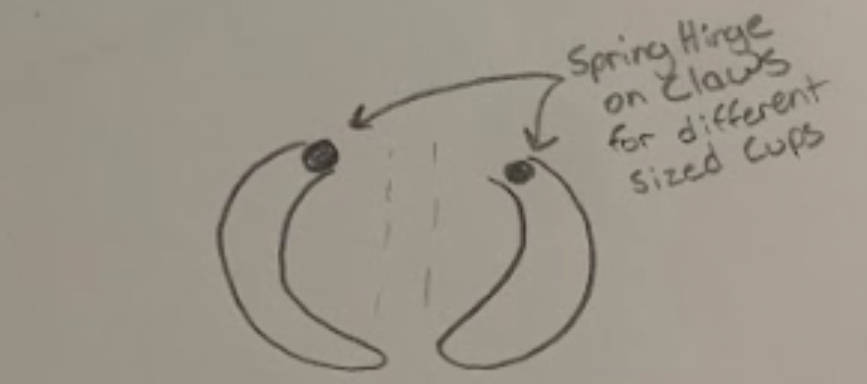

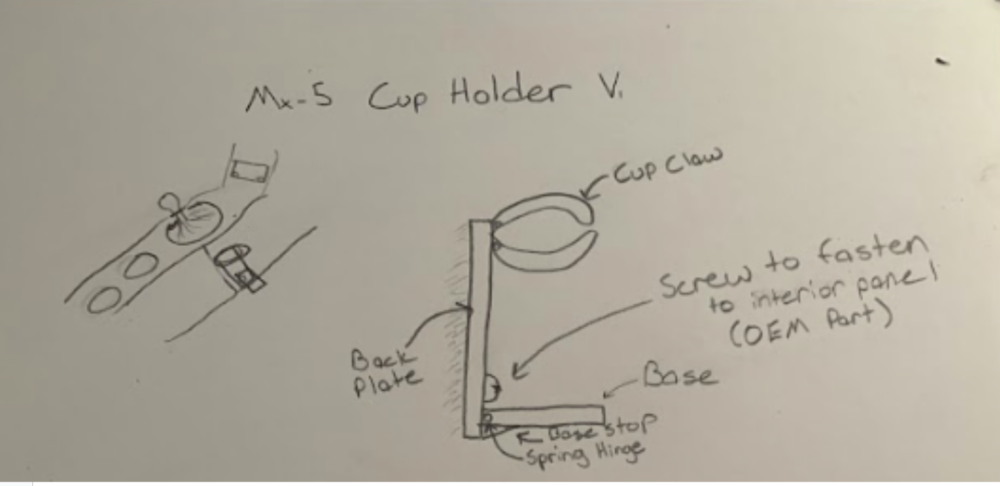

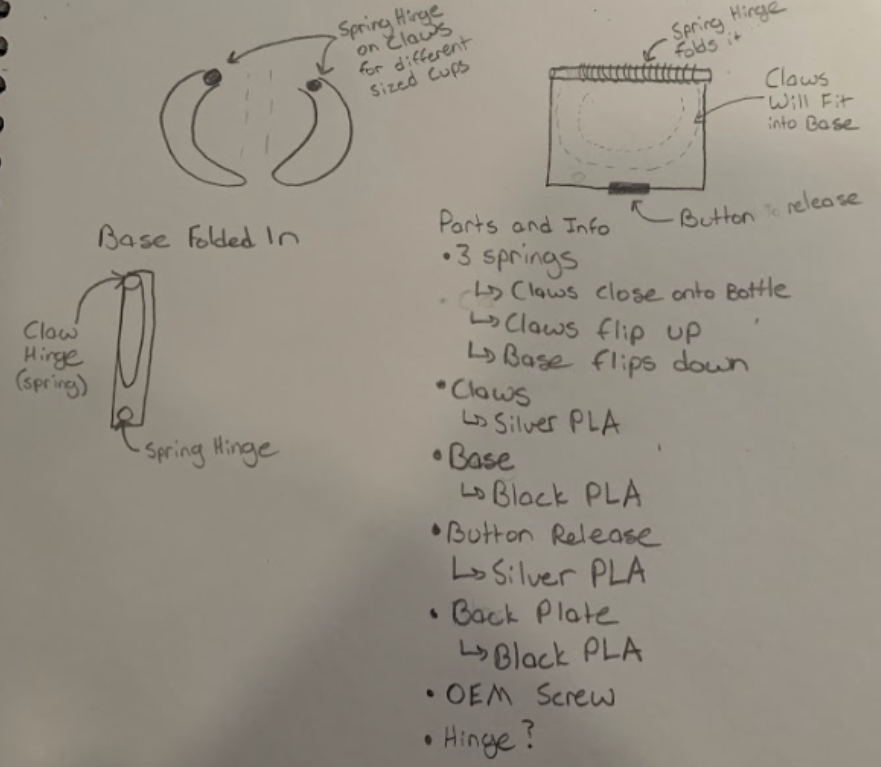

Below you can see the sketches of my design for reference of the constraints and specs.

These were the specifications I came up with for my project borrowed from post 8.

The design needs to look like it’s an OEM (Original Equipment Manufacturer) piece. This means that the design looks like it’s something you can purchase from the Mazda factory as an option on the car.

The design needs to fit onto the car without any need for additional modifications to the original car design. This means that the design shouldn’t require me to cut, damage or modify any of the existing aspects of the car.

The design needs to be able to accommodate multiple cups, bottles and other items. I would like to be able to use the cupholder for not only my water bottle but other items as an extra storage piece which allows for an additional “dynamic” portion of the project.

The design also needs to be able to support adequate weight. This will be decided through testing but a full metal water bottle can be quite heavy, so I want the design to be able to support this.

The design also needs to be able to hold in place under motion. I wouldn’t want whatever is housed in the holder to fall out when turning or accelerating.

The design needs to be able to be easily accessible when driving. The holder cannot be too strong to where it’s difficult to remove the object while driving but also difficult to place the object back into the holder as well.

I am planning to prioritize the overall use of the design so including the strength, and function of the design over the dynamic and aesthetic. Although, I don’t want to compromise and not include these specs in the final design.

Constraints

I will need to strengthen my 3D printing skills. I have little experience and I think it will take time to polish the design through multiple prints to achieve the ideal design. As mentioned in post 8, my planned design includes a lot of moving parts with snap fits so trying to achieve these efficiently might be quite difficult.

Practicing my tolerancing skills. Trying to achieve snap fits for springs and hinges will be quite difficult with a 3D printed part and will require a lot of work and iteration to get things to fit properly.

Another constraint would be the time, I am currently under a lot of pressure with other schoolwork, so I am worried that I might have issues with printing it multiple times and things of that nature.

A big constraint is sourcing the springs needed for the design. I have yet to find model I think would work for my plan of taking it apart and reusing some of the components so I think I might have to switch to the alternative idea of using the elastic mesh netting.

Lastly, a big constraint of mine is the 3D printer being used. Currently, my 3D printer at home has a few issues that I am still sorting out. An easy fix for this would be to use the idea forge 3D printers but that would take a lot of time and planning to make work.

Overall, the toughest constraint will likely be the sourcing of components and time constraint.

1 Comment. Leave new

I think this is a great idea. From the sketches, it seems to be a really useful device and a common problem for drivers. you could potentially go to market with an idea like this. Great job i look forward to seeing the finished product!