Hey everyone, for my final project, I designed a 3D printed shoe midsole using a futuristic and organic aesthetic. I have been a cross country runner for the last ten years, and I have developed a bit of a passion about what runners wear on their feet to perform so well.

Running shoe technology has come leaps and bounds over the last couple of years. From old and cheap foam slabs that professionals ran marathons in have come some of the most technologically advanced propulsion innovations underfoot. These innovations have pushed humanity to tons of new world records, including a sub two hour marathon. These innovations have included suspension via air units within midsoles, carbon fiber plates and stiff inserts in midsoles, and lighter and bouncier foams. These technologically advanced foams, combined with stiff and reactive carbon fiber plates, have led to the development of a new classification of shoes: the super-shoe. These bouncy and responsive shoes have taken the running world by storm, and have produced some of the fastest racing times ever when worn by elite athletes. Nike even claims that some of their super shoes can give the user a 4-5% energy return.

Why do I say all of this? The technology put into these shoes, along with the more expensive materials, has resulted in a dramatic inflation in the cost of running shoes. Elite running shoes were once approximately $100, and now they have almost tripled in price. This has made great running shoes nearly inaccessible to an entry level runner. Next, the durability of these elite running shoes is substantially lower compared to shoes from just a few years ago. This leads to a much faster depreciation of the shoe’s “life span,” or the ability of the shoe to be responsive to the runner’s foot strike. Finally, these shoes are not easily recyclable, as foam is extremely difficult to break down and reuse for other purposes.

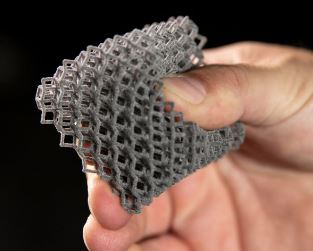

As a potential solution to all of these reasons, I decided to create a 3D printed running shoe midsole. This has been attempted before by companies like Adidas and Brooks, but those shoes still fall into the category of drastically overpriced. I decided to use the Idea Forge Prusa 3D printers with TPU plastic material. Both of these are widely available in the 3D print community and are generally easy to use. Also, I used a gyroid infill for the shoe. This achieves an isotropic response properties to various forces. It also was so I could achieve a compressibility factor of the shoe, which is my moving component. By choosing a low infill density, the TPU plastic was reminiscent of a running shoe foam, similar in compressibility and response.

I did all of this in the spirit of making a running shoe that breaks through the “glass floor” of running shoe prices if you will, and provide people with an easy and affordable alternative to expensive running shoes. TPU is also a recyclable material as a thermoplastic!

For my aesthetics, the gyroid infill is completely exposed on the sides of the shoe, giving the midsole a futuristic aesthetic, as well as an organic look with the natural curving lines.

Thank you for reading!

2 Comments. Leave new

Jace, your project looks really cool. I appreciate all the thought and research that went into the background for this; it’s cool that you’ve considered the current state of the running shoe market in both financial and environmental terms in order to approach your own shoe production. If you had to guess, if your shoe were to be produced and made available to consumers, how much do you think it would cost in comparison to the industry standard?

Hey Jace the final product is looking great! How much post processing after taking it off the printer did it require?