Introduction

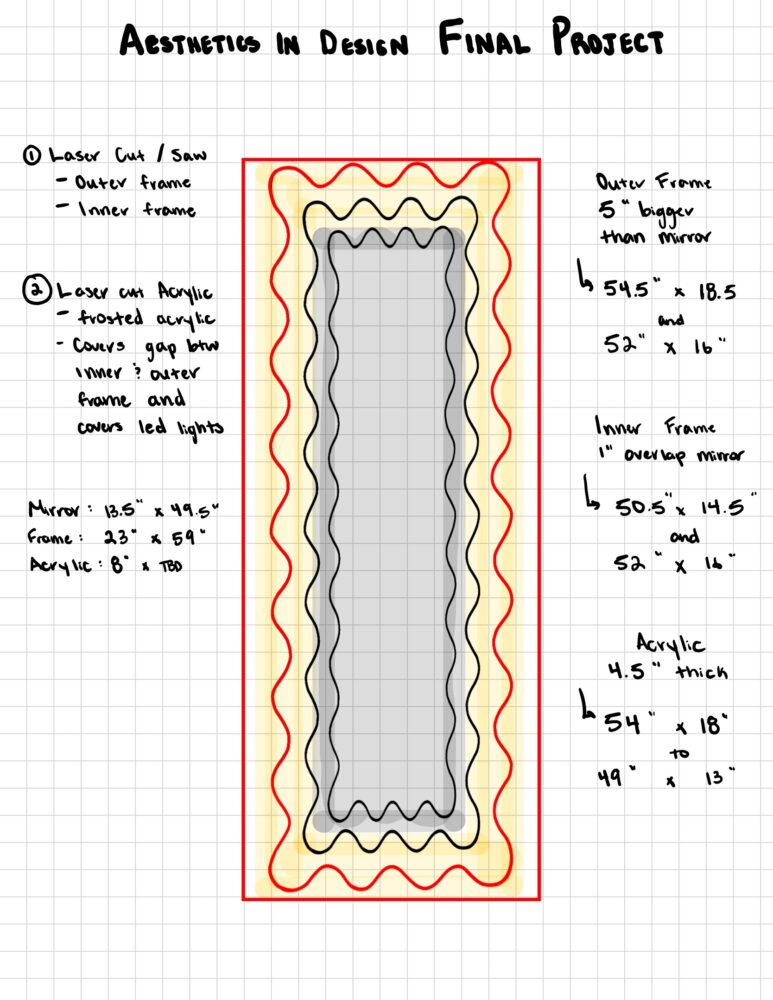

I have been working on creating a mirror with lights and a wavy styled frame that is in the organic modern aesthetic. Since the design report, I first re-drew my sketches in more detail and with exact measurements and listed out the materials and size of each component. I need to laser cut the wavy design on wood and then cut out strips of foggy acrylic that will lay between the frame and the mirror. The most challenging thing was the scale of this project. Originally I was going to use a 13.5” x 49.5” mirror but after lots of deliberation and trial and error I decided to move towards a smaller size so I am able to cut the piece as one in the laser cutter. After finalizing my new dimensions I went to Home Depot to select the wood I would like to laser cut and I chose a ¼” Birch Plywood 2’ x 4’. I am currently planning to not use paint to cover the burnt edges and stick with natural wood for my aesthetic but if it is too noticeable I plan on staining the wood to keep a nice blend.

Currently

To start assembling, I first focused on the frame itself. Based on the measurements, I created a hand drawn wavy design through Illustrator on my iPad and then imported the file to my computer through rhino to manipulate the lines. I focused on the frame first because I thought this would be the most complicated part and I have not used the laser cut in this scale before. I then plan to cut the acrylic in 8” strips and lay them out along the frame in a rectangular shape. Then to finalize the assembly I will mount the mirror itself first, then attach the led light strips (and have the remote/wiring attached behind the mirror), followed by the acrylic and finally the plywood frame. Pictured below is my more detailed sketch of my mirror with measurements and materials.

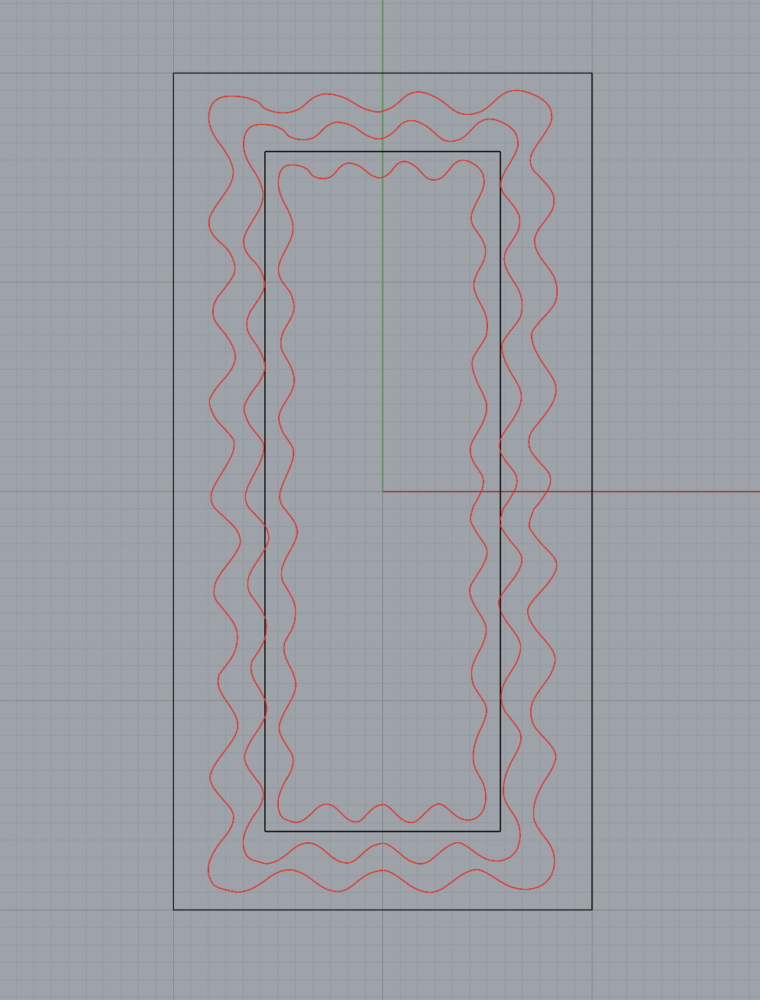

I have completed collecting all of my materials and the Rhino file itself. The file consists of the wavy design I will actually cut out and then guidelines for scale like the mirror and dimensions of the entire frame. I have set time early this week to laser cut the wood and time later in the weekend to finish cutting the acrylic and assembling the entire piece. Since my dimensions are slightly smaller I hope to laser cut the frame in one piece and also keep the purpose of a free standing mirror. Pictured below is my current CAD design within Rhino.

Looking forward

Moving forward, I plan to focus on laser cutting/any cuts in general first because these will be the most time consuming. However, I do want to keep planning ahead my fabrication process once I am finished with my cuts. I think I am still following the planned aesthetic I chose but I hope the assembly process will go smoothly. I realized my original timeline was incorrect due to the many due dates and posts for this assignment so I have less time that I originally thought I had. I hope that I can keep moving forward and making progress although I am overwhelmed with many other final projects.

I am excited to continue updating you all on my progress and soon show my final result. Thanks for reading!

2 Comments. Leave new

Your project seems very meticulous and carefully planned! It’s impressive how you’ve addressed the challenges of size and material choice to achieve the look you want. Your focus on detail in every step is clear.

Hi thank you for your feedback! Thank you for supporting my setbacks and providing helpful insights. I greatly appreciate it!