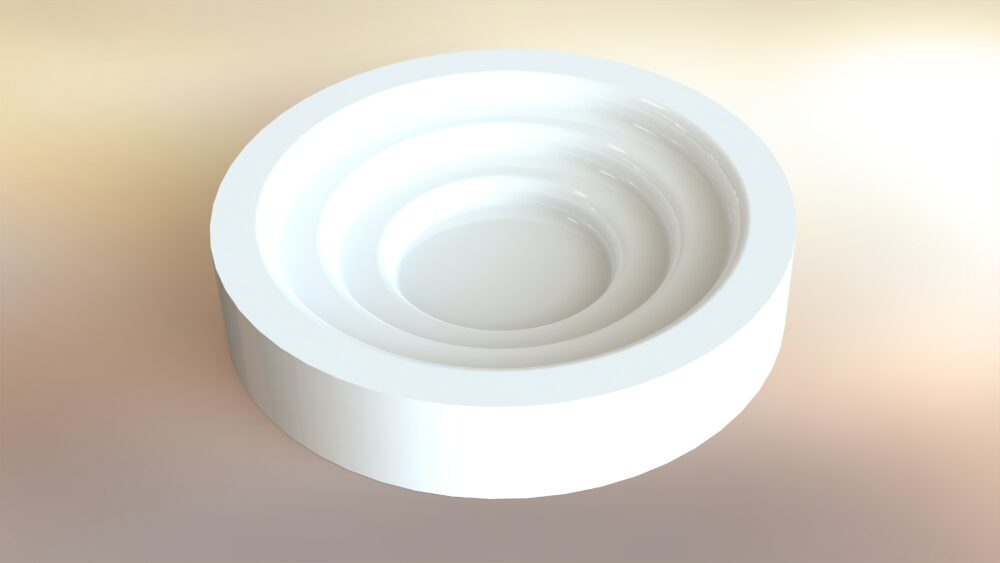

My design so far has had to be completely re-designed. Originally, I was planning on creating something that looked like this:

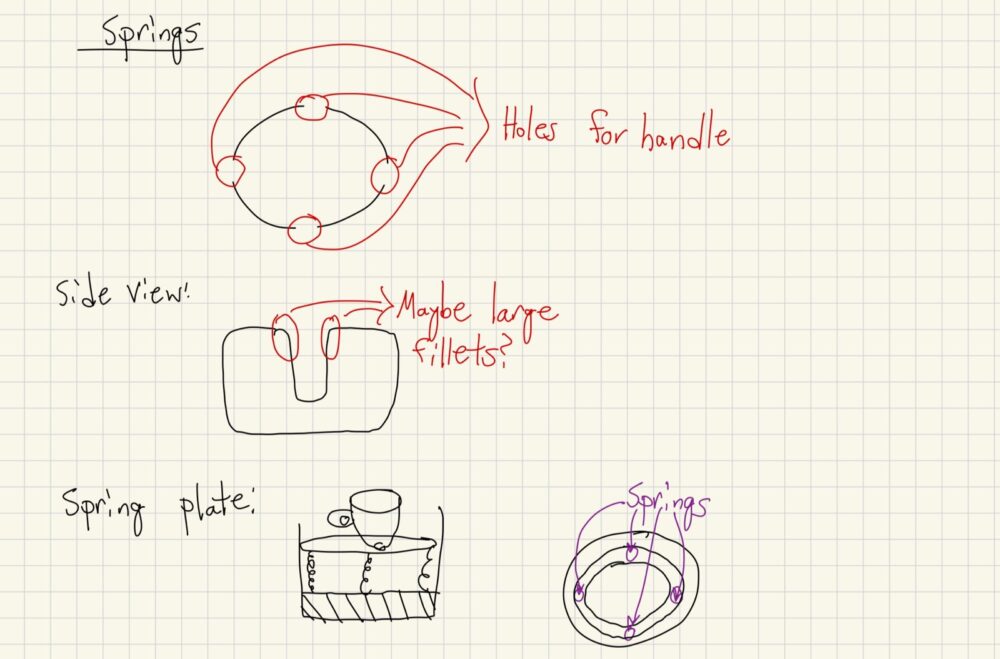

However, after some really helpful critiques from my pod members, I have decided to redesign my coaster to feature a spring mechanism instead of the multi-tiered level design as shown above. I’ve created some preliminary sketches for this, attached below.

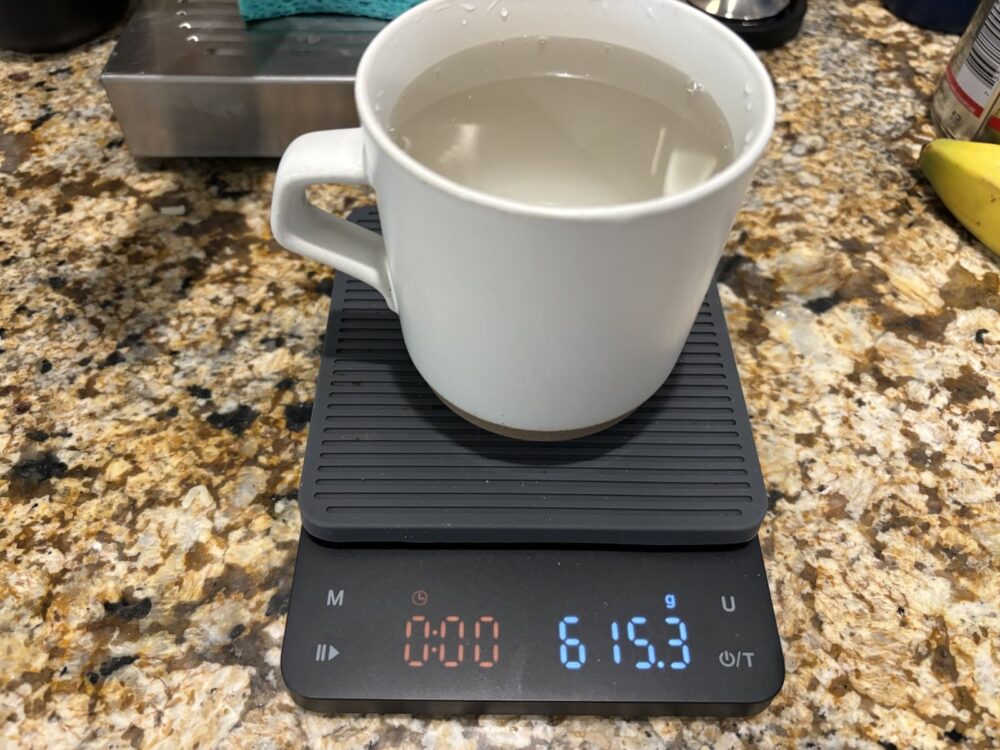

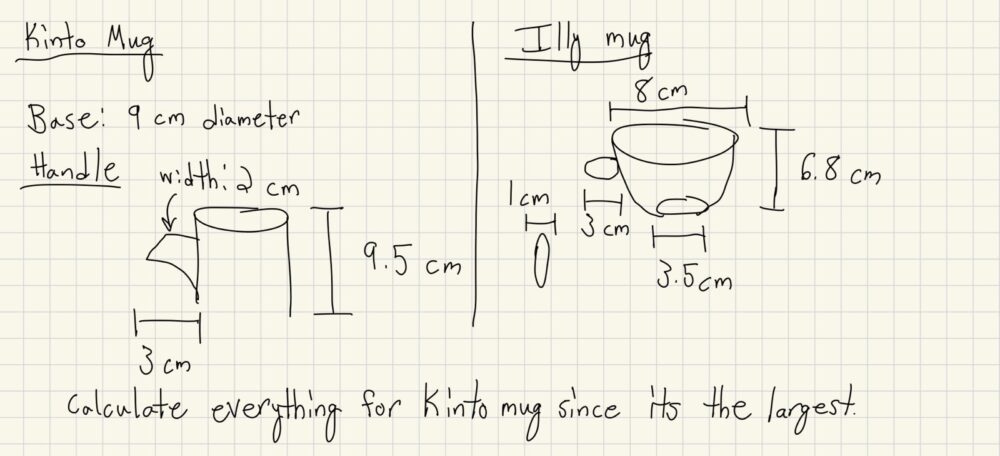

To ensure that the spring would be able to handle one of my large mugs, I took the two most common mugs, filled them with water, and weighed them with a scale:

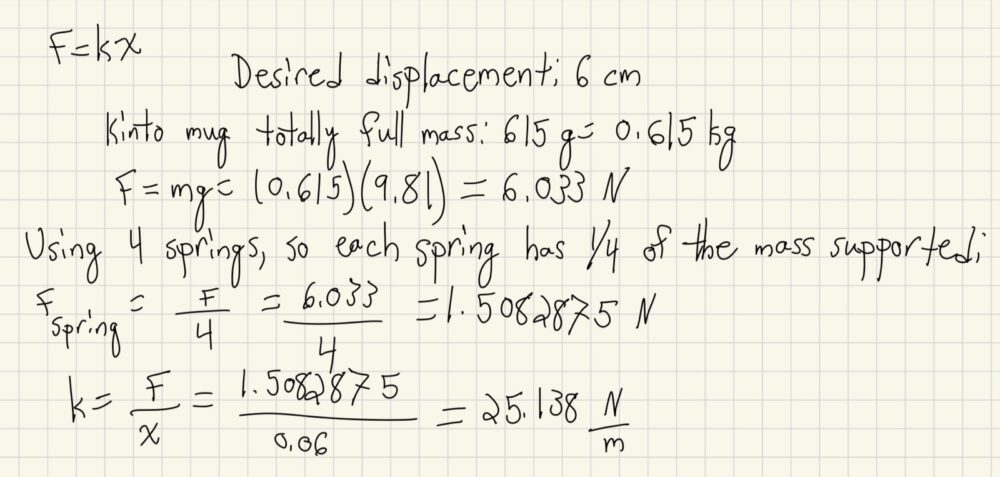

To ensure that the springs would compress adequately, I took some preliminary measurements and calculated the spring constant needed, assuming that I have four springs on the top/bottom and left/right sides of the spring plate on my coaster:

I have since purchased some springs that roughly meet these specifications. I am also currently working on some software that will give me a range of acceptable spring constants that will work given the spring dimensions. Amazon sells several cheap spring sets, so I’m going to see if the dimensions from some of those springs will work well for my coaster.

My immediate next step is to create an updated CAD model, included with the springs. I will also be including slots on the sides of the coaster itself to allow for the mug’s handle to pass through.

4 Comments. Leave new

Hey Josh, keep it up! for reaching final design for your artifact. I like the detailed sketches, mug measurements, and methodical approach to ensuring the functionality of your coaster design. It’s commendable that you took practical steps such as weighing the mugs and purchasing appropriate springs based on your calculations. As you proceed with your updated CAD model and integrate the springs into your coaster design, have you considered potential challenges or adjustments needed during the assembly process?

Hi Aryan,

Thank you! To answer your question, yes I have. That’s why I’m 3D printing everything; I’m using a low quality print as a first pass so that I can test tolerances and everything. The final print will be made out of something much nicer once the tolerances fit.

Hi Josh,

It looks like you have put a lot of thought into your project so far. I appreciate that you have been doing an analysis of your design to prove that your design will work. I think you are on the right track moving into CAD next and purchasing materials. I am looking forward to seeing how it turns out!

Hey Ian,

Thanks so much! We’ll see how it turns out; I’ve also purchased a lot of other springs in case something goes wrong and the springs I think work end up not working for whatever reason.