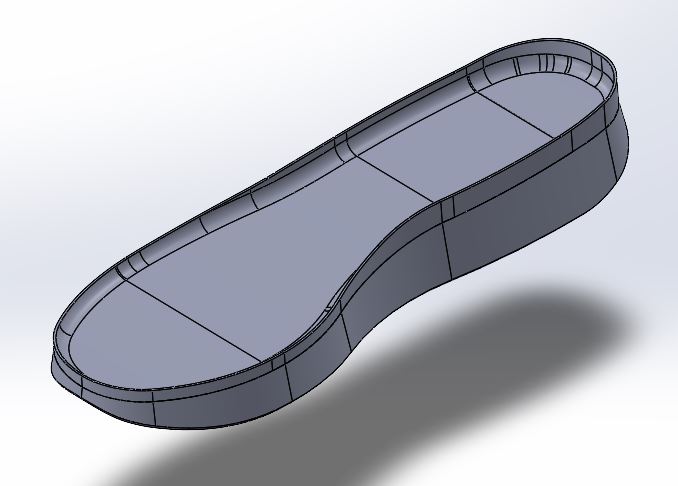

Hello everyone, I am making a 3D printed running shoe midsole for this project. Since the design preview, there have been multiple updates, some problems, and a few new steps required to get to where I want to be with the project. Also, I now have a completed real-life prototype!

Before the design preview, I had tested seven TPU plastic blocks with different gyroid infill densities to see which one most resembled the foam of a shoe. After polling my cross country team members, I was able to select an infill density with reasonable accuracy. Last week, I submitted my initial computer design model to Patrick Maguire at the Idea Forge. This initial model included a right and left shoe, at what I thought was a men’s size 11.5 shoe. He got back to me before printing, saying that the bed size of the 3D printer I was using was too small for my model. To fix this, I modeled just a right-side midsole, and asked if he could print on a diagonal in the horizontal and vertical directions. This orientation allowed the model to fit on the smaller Prusa MK4 printing bed, although I did have to pay more for support material.

This print took a long time, and I was able to check on it periodically over the course of two school days. While the model was able to fit on the bed, the vertical diagonal was approximately a forty five degree angle, which impacted the print’s adhesion to the support material and overall stability of the part. I believe that this angle also impacted the aesthetic appeal of the outside of the shoe midsole, which looked a little messy and melted by the time the print was complete. Lastly, this angle had a substantial impact on the base shell layers, because the slicer had trouble understanding where the base of the model was with the new angle adjustment.

Once I picked up the print, I immediately realized that I made an error in sizing. My CAD model measurements were to the outside edges of a more “flamboyant” shoe with a large heel flare, and my measurements did not adjust for that. Because of this, my shoe has the width of a men’s 11.5 shoe, but the length of about a men’s size 13. Other than this error, I was generally happy with the sizing of the shoe.

I did multiple pressure tests on the shoe by stepping on it stationary, walking over the part, and jumping on it. These tests showed that the plastic responds in a very similar way to foam in normal running shoes, but TPU plastic does not have great elastomeric effects, and so the midsole was not as responsive as more high quality running shoes.

For the continuation of this project, I am going to re-size the shoe to better fit my men’s 11.5 foot, and look to re-print with the Idea Forge. Hopefully this size change will make it substantially easier to print on the Prusa printers. Once the 3D print has been sized, I can fit it with an insole and begin designing an upper!

2 Comments. Leave new

Hey Jace, you have made quite a good progress! The process of testing different infill densities and soliciting feedback from your cross country team really shows a proactive effort to refine your design based on real-world testing and user input. Additionally, your willingness to learn from challenges such as the sizing error and the impact of print orientation on aesthetics and stability shows resilience and adaptability in the face of technical constraints. Considering the challenges you faced with the initial print, have you explored alternative printing methods or adjustments to the slicing settings to improve adhesion and overall print quality?

Hello Jace,

I think its really cool that you have your prototype! If the size change doesn’t make much of a difference to your printing error, what do you plan to do? Would you top the midsole with something to add to the aesthetic? I think your project idea is super cool and I can’t wait to see it play out!