My project is to make an Organic Modern mirror that is functional and also a decorative piece. After my initial design stage, I have come up with my top 5 specifications and top 5 constraints that I will go over below.

Top 5 Specifications

1. My top specification is to make a mirror in the Organic Modern aesthetic. I really like how this aesthetic looks in an interior design space and how it is able to go with a versatile amount of pieces. I want to create a functional piece of furniture that also acts as a design element that can be used in many different spaces. I hope to continue to use this mirror in the future and other living spaces since it is minimalistic and more sophisticated. I hope to achieve this by using either a neutral colored wood stain or a white paint for the wood as well as a semi transparent acrylic for the lighting feature. I am planning on not adding a mounting feature because I personally have never used a hanging floor length mirror in my space and I always have my mirrors leaning against a wall. An example and inspiration picture for something I am going for is pictured below.

2. My second specification is to make a lighting component as my dynamic feature. I hope that the lights will turn out well and that the lights will not take away from the frame itself. I plan to use LED light strips that I will attach to the mirror itself and then cover them using a semi transparent acrylic, which will be a part of the frame itself and still allow the light to shine through. I’m excited to have a mirror which I use daily and also add a lighting fixture for my interior design space.

3. My third specification is to fabricate a design that actually works. As of now I am thinking of using the laser cutter for both plywood and acrylic. I have never used the laser cutter for this large scale of a project so I think this will be a fun experience. I would love to be able to cut out the frame on one piece of plywood which will cover the perimeter of the mirror so I don’t have to face the difficulties of covering the seams.

4. My fourth specification is for it to be large enough to still be a functional mirror but also not too large where it is hard to transport. I am thinking I will have to cover a little bit of the mirror in order to cover the existing frame where the LED lights will lay. As seen in my sketch below I plan on creating multiple “layers”. I plan to start with the led lights directly on the mirror, followed by the rectangular cut out of semi transparent acrylic, and finish with two sets of plywood wavy frames that act as the outer and inner edge of the frame.

5. My fifth specification is properly staining or painting the wood and staying in the Organic Modern aesthetic. I want the mirror to be neutral and have minimal textures so it can fit with many different locations. I also want to make sure the seams between the frames (if I were to laser cut the frames in different pieces due to the scale of the project) were not visible and be durable to last a long time.

Top 5 Constraints

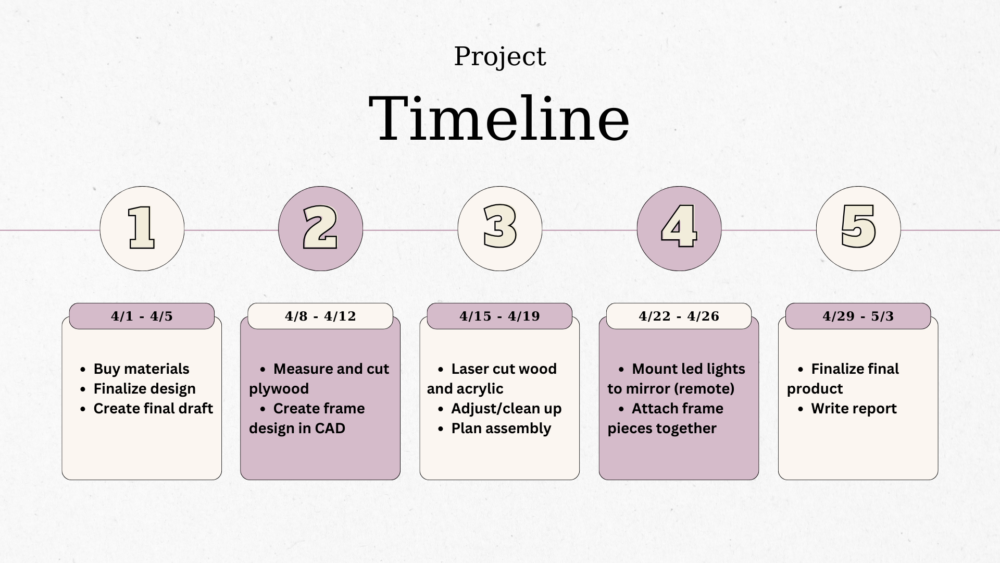

1. My top constraint is most likely time. I am currently not sure how long this project will take because I have not created this large of a piece of furniture before. Due to this, I want to start measuring and creating my CAD design as soon as possible so I can buy the right amount of materials and laser cut. I have already started to purchase the mirror itself and the led lights but I need to dive deeper into finding a large enough piece of plywood that is laser cut approved and acrylic that will still let the light shine through. Below is my rough estimate and timeline to allow me to stay on track.

2. My second constraint is making the frame for the mirror. Since I only have very little experience using the laser cutter on a smaller scale, I want to allow enough time and resources to figure out the correct scale for the cuts. I need to get enough materials to practice and have different prototypes if it doesn’t fit perfectly the first time.

3. The third constraint is attaching each element to make one whole piece. If I face the challenge of not being able to laser cut the entire frame in one piece, I will need to figure out how to glue the pieces together without too much attention to the seams. I am using the laser cutter, which results in a slight burnt effect to the edges, so I will most likely need to paint or cover the discoloration in general. This will require me to learn new skills so I need to plan out my project very detailed so it turns out well.

4. My fourth constraint would be the other commitments I have. During this project, as well as the due date for this project, I have another big final project that incorporates 3D modeling and laser cutting as well and more weekly projects throughout. I need to set specific deadlines for myself each week so I can avoid putting this project off at the last minute and causing myself more stress.

5. The fifth constraint is not having access to any woodshop tools. I am very new to all of the 3D and laser cutting machinery but I had to learn how to use them this semester because of other class assignments. I unfortunately haven’t had the time to take the woodshop orientation so I cannot use table saws to cut my design. I am going to need to manage my time and resources in order to successfully cut my design and not face too many setbacks. I think a table saw would be helpful in order to cut the design by hand and in one piece but the laser cutter might be more useful for the wavy design in relation to consistency and cleaner lines. The laser cutting machine may be busy with other projects closer to the due date so I will need to plan ahead.

2 Comments. Leave new

Hey Emilee,

I think you’re admission of needing to practice a bit with the laser cutter and get a feel for how everything is going to be put together is great. So many people (myself included) would try and go for it right off the bat. And while that sometimes is the right approach, I think yours is also a good idea. Have you thought about any of the stain colors for the wood? I know you had mentioned a neutral color, but have you decided what that would look like at all?

Best of luck with everything!

Great work on the post Emilee. I really like the idea behind this project and the aesthetic you are going for. Have you considered using the machine shop to cut the plywood instead of using the laser cutter? The laser cutter can only cut thin pieces of wood and I am not sure if that will be strong enough for your design. I am excited to see how this turns out.