For the project, I’ve decided to spruce up a prototype I made last summer and hopefully create a nice housing. The prototype is essentially a swamp cooler with less humidity. The inspiration of it came from camping in New Mexico during the summer. When I went, it was unbearably hot and I didn’t want to run my car overnight for A/C in the middle of a desert(I’m not a backpacking camper-more of an overlanding type). I thought about buying a typical swamp cooler, but I usually travel to places where adding humidity is not the best idea. I also looked at portable air conditioning products, but those are not priced for a college student.

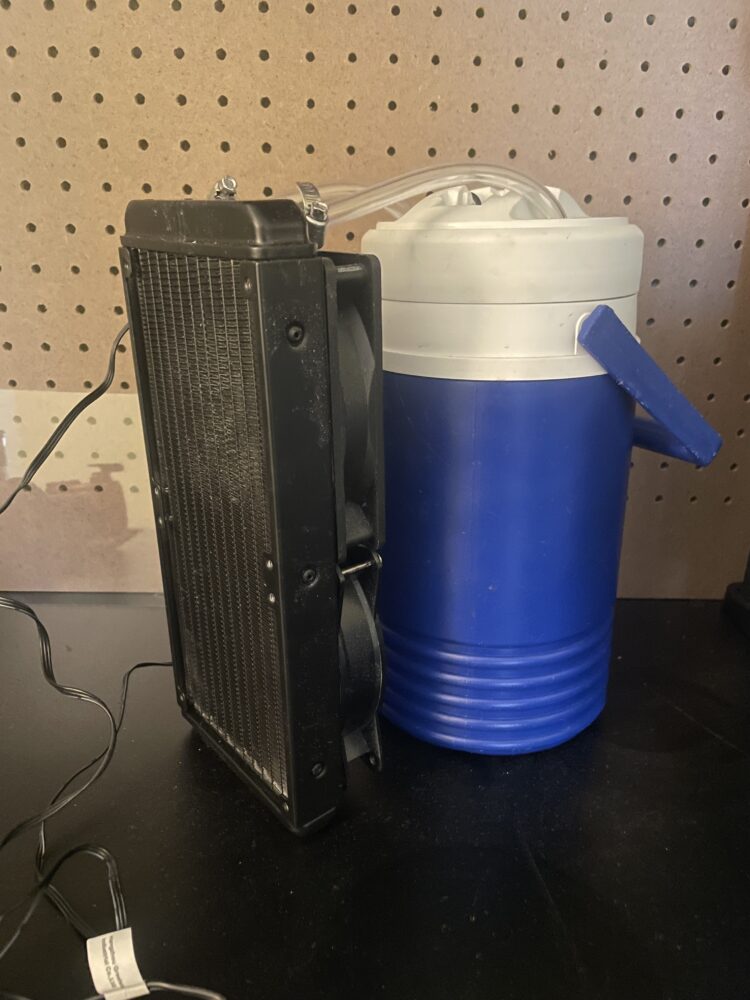

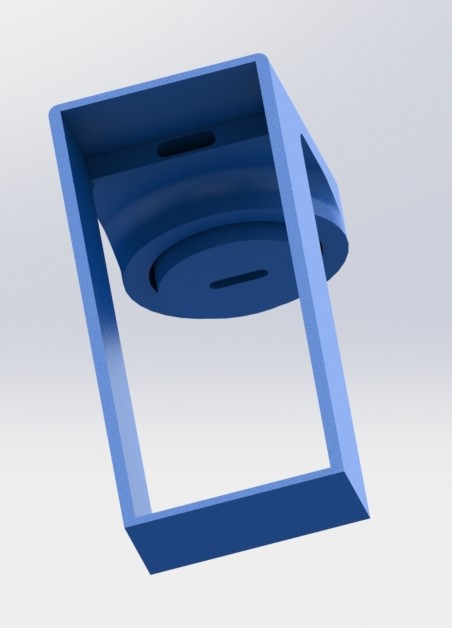

Prototype design

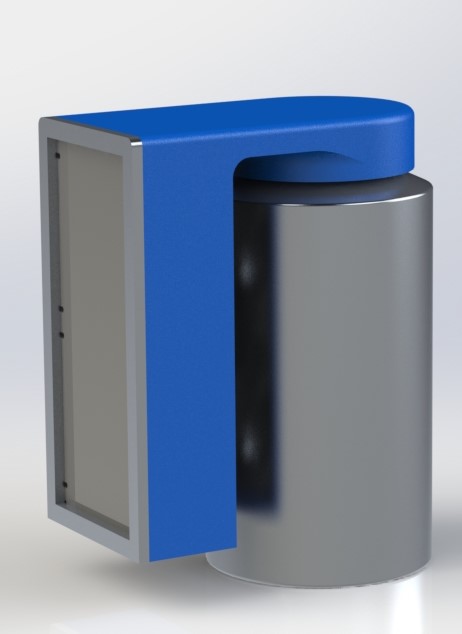

The aesthetic I am aiming for is minimalist yet rugged look. I don’t want to use an unnecessary amount of material to house everything, so I designed it to only house the main components, and not the cooler. I think this is more of a decision based on function, but because I’m making it compact, I think it could have a clean and simple minimalistic look. The reason I am adding a rugged look is because I want to include more materials than plastic, which will be used for the main housing. I’ve always liked the look of exposed covers and fasteners, so that’s a design element I am aiming for.

Ozark Insulated 1 Gallon Water Jug, Walmart[1]

I purchased an aluminum 1 gallon cooler with a nice polished finish on it. For the color scheme, I think a black housing would look nicely with the metal finish and dark gray radiator. The renderings I used have a blue housing, but that is only for rendering as matte black doesn’t show details well on screen.

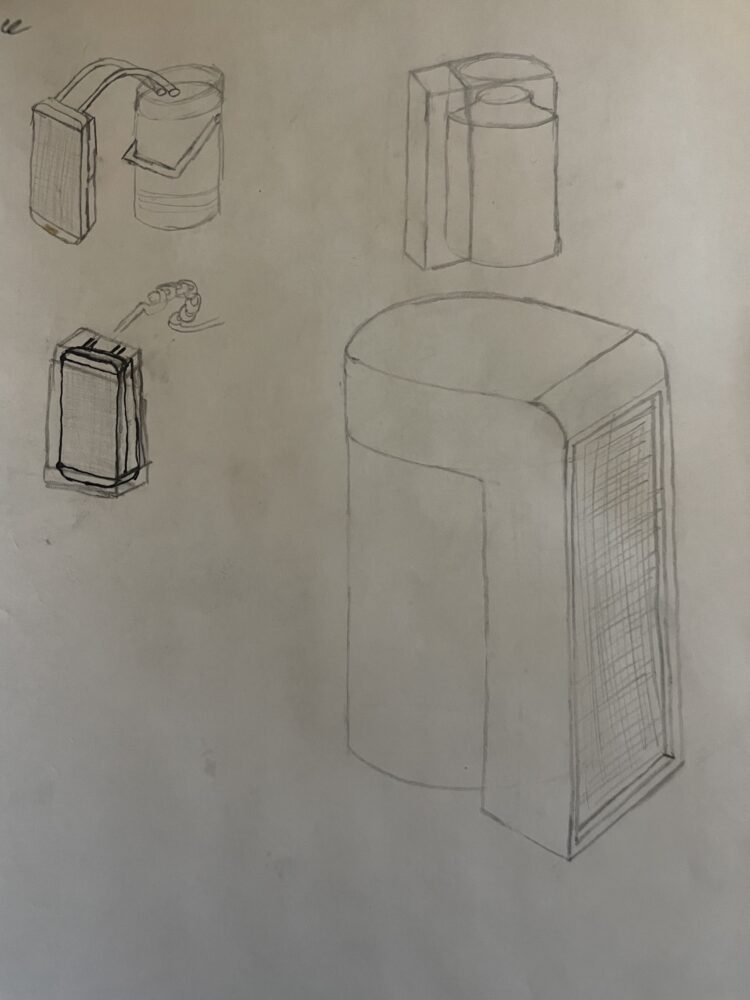

Initial sketches and idea

For this initial design, I came up with the drawings above for a baseline of what I need. I kept the shapes simple and fileted some edges. This design is honestly as minimalist as it gets. Every part of the housing is needed for a function and kept simple. I do think more refining is needed, but the current design is a good starting point. One component missing is the mounting parts. I am integrating it into the housing, so once I have final dimensions of everything, I can work on the mounts.

Rendering of entire system

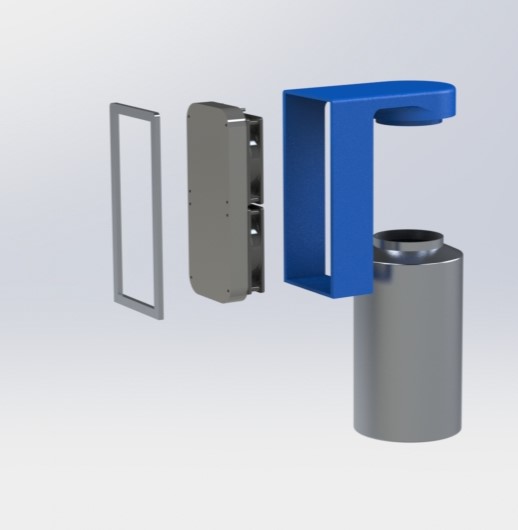

In terms of components, I only have to design the cover and housing. I plan on designing mounting points for all the internal hardware so I don’t have to fabricate additional parts. Other components are bought, such as the heat exchanger, water pump, battery, and cooler. Ultimately, this is a housing design and packaging project since I figured out all the other details for the prototype(there weren’t many calculations).

Exploded view of main components

I couldn’t find a way to work with metal on campus, so I have to 3D print the housing. This kind of works out because it will be lighter, but I originally did want to make something out of billet aluminum. 3D printing should be straight-forward, I have experience using 3D printers so I am not too concerned about the actual printing. I would like to make initial test prints from the normal 3D printers, but for the final print I would like to submit a request to use the higher quality printers on campus. I would like the project to be as clean as possible, and the quality of print is a huge factor for me.

The cover should be simpler to make than the housing. It essentially is a plate with an opening and mounting holes. I do not think this would take too much of the metal shop’s time, so I plan on asking if they can water jet it out of aluminum. I think the aluminum could match well with the metal cooler I am designing around. If they tell me no again, then I’ll just settle on 3D printing it as well.

The actual cooling mechanism is simple: cold water is pumped through the heat exchanger. This breaks down to a water pump, radiator, and some hoses. All these components can be integrated within the housing. I plan to make mounting points for all these components while I redesign the housing after test fitting. Currently with my prototype, all the parts are just hanging together.

Housing rendering

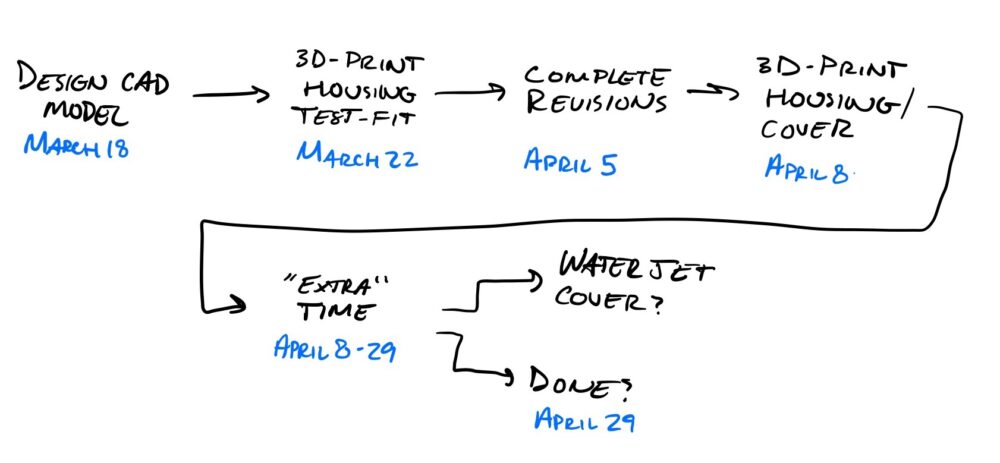

For a timeline, I plan to 3D print a test fit housing by March 22nd. The current design was to get an idea of what my drawing could look like, and the current tolerances can be worked on. By April 5th I hope to finish revising every detail and prepare to 3D print a final version. I’m planning on finishing early because I never complete projects as soon as I think I can. So, I added plenty of extra time to make up for it. Hopefully, I’ll have a nicely put together working project by April 29th, the presentation date.

Timeline

Citations

[1] https://www.walmart.com/ip/Ozark-Trail-Stainless-Steel-1-Gallon-Water-Jug/285297047?wl13=5341&selectedSellerId=0

2 Comments. Leave new

Hi Kevin, I love the idea and background of your project. I really like the combination of aesthetics of rugged and minimalism, since the design still needs to be rugged for its camping purposes. I also like your choice of water bottle for the new design, and how it pairs with the housing. Have you considered adding a mesh to the front venting on the radiator? I feel like that would tie in nicely into your design. Good luck with the rest of your project!

Kevin,

This is a great idea and obviously well thought out. It is nice to know that you have some alternative fabrication methods if things don’t work out. I got a bit confused about the coloring of the project when you started to talk about the aluminum, is that something you plan on painting? On an unrelated note, what’s your overlanding rig?