Here is a recap of my project idea so far.

For my project, I am planning on making a lamp either for my desk or bedside table. I want it to be something that I can turn on late at night to provide me with light without keeping me awake. This would be done through the use of a smart lightbullb that is able to project a softer, warmer tone of light than most lightbulbs currently do. I also want the light to be indirect, as I have found that diffused and indirect light help me fall asleep better.

The aesthetic I have chosen for my project is Scandanavian. Scandanavian design is almost an extension of minimalism. It includes natural tones more intentionally, and additionally focuses on creating a comforting environment. This is drawn from the Danish concept of “hygge”. Hygge, while not directly translatable to English, encompasses the concept of coziness and comfort. Scandanavian designers accomplish this through the use of warm tones, natural materials like wood, and clean lines.

For my lamp, I am going to take inspiration from the designer Seppo Koho and his work at Secto Lighting. Secto is a design group that creates handmade wooden lighting, from Finland. Shown below is my sketch of my lamp. The goal is to have the light diffuse outward and down, to avoid lightening the entire room too much.

As of right now, I have not been able to create a SolidWorks model of the lamp. I have run into issues with my serial number but I am actively getting that resolved. I will update this post when I finish it. I plan to order some nice wood online, or maybe purchase some if I can find it in Boulder. Right now, I am thinking of using cherry wood or maybe white oak. However, it will depend on what stock is available for the size I need.

Here is my initial sketch of my design:

Here is my model of the design. I am going to hopefully be using some semi-opaque plastic to help diffuse the light. This will also help to hide the lighting fixture.

Once I get my stock in, I will likely be using the wood shop and laser cutter. I am aiming to get a softer wood that works well in a laser cutter, but that may be a game time decision I need to make. I am planning on making some test cuts first to see how it goes. If all goes well and I am able to cut the pieces from the laser cutter, I will be using wood glue to join them together. I will do any and all finishing in the wood shop. I am planning to apply some kind of finishing coat to my wood. The specific substance will likely depend on the type of wood I choose and how it will look with a stain.

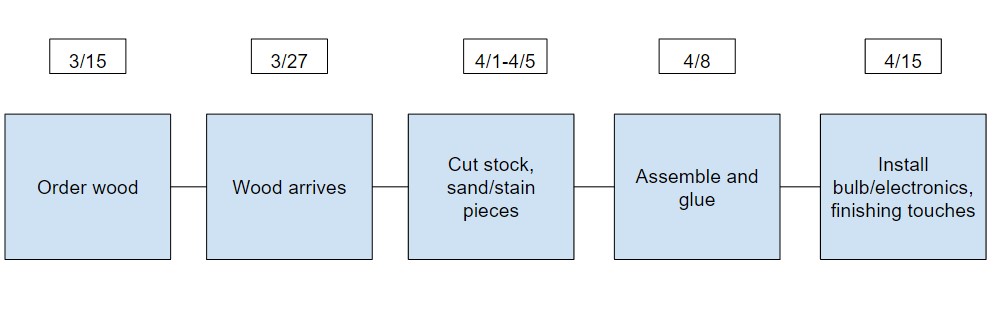

Below is my approximate timeline for this project.

By the end of this week, I plan to finish my research into the wood types that both fit my aesthetic and will be able to be laser cut. Then, I will purchase the wood (likely online).

I’m accounting for the wood to take roughly two weeks to ship. This will help give me some buffer in case the wood gets here faster and I need to make up time later on.

During the week of 4/1, I plan to go to the ITLL to cut out all of my pieces. Because of my design, the pieces should be simple to cut out of a stock sheet. After they are all cut, I plan to sand them and do any finishes during that time. I want to get that all done prior to trying to assemble it. Additionally, I am going to give the pieces time to dry and set before trying to assemble them.

On 4/8, I am going to assemble everything and glue it all together. I am hoping to avoid using fasteners as much as I can. I think that any visible screws would detract from my project.

After gluing everything, I am going to give the wood glue ample time to cure. I have had bad experiences with trying to work with a project before the glue has set. So, on 4/15, I plan to install the electrical components and to add the smart bulb. From there, I will do some testing to make sure everything functions as intended.

This will give me about a week before the project is due to deal with any issues that arise. I want to give myself lots of time, because my woodworking skills are a bit rusty overall. So I think that giving myself time to do redesigns and to really make the project look good will be beneficial to the quality of the final project.

1 Comment. Leave new

Hi Jonathon. I think the shape of your design is clean and effective, and I bet it would have a interesting lighting effect when the bulb is turned on. I am wondering if you’re going to use a protectant on the wood, since artificial light might degrade soft woods, or use a fixture for assembly to make sure everything stays in place while your pieces dry.