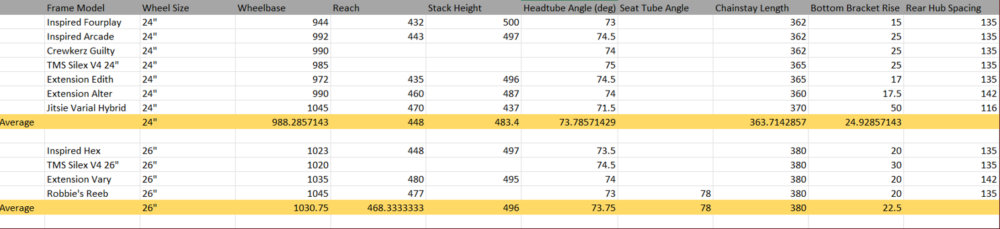

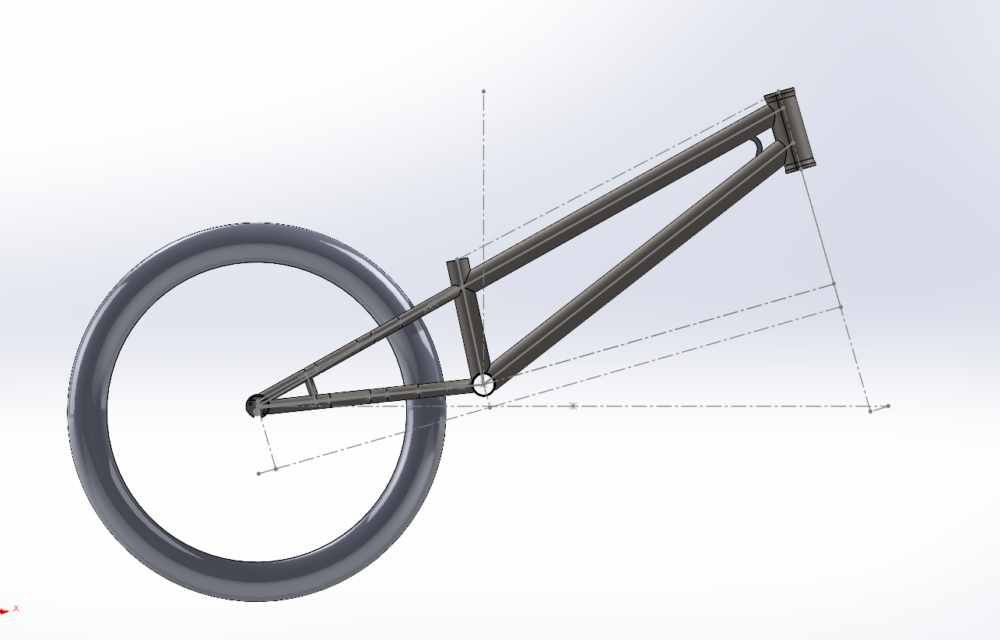

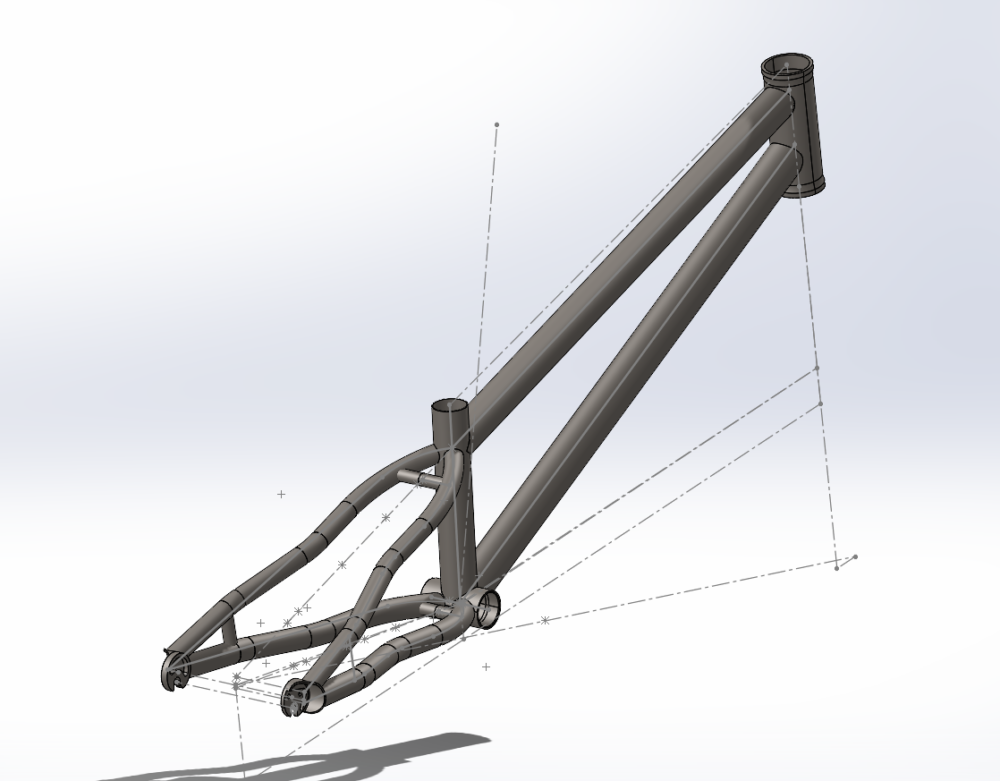

- Reach: 475 mm

- Chainstay Length: 362 mm

- Bottom Bracket Rise: 30 mm

- Head Tube Angle: 74 degrees

- Seat Tube Angle: 78 degrees

- Wheelbase: Will be determined in CAD (Dependent on fork)

- Stack Height: Will be determined in CAD (Dependent on steer tube)

- Rear Hub Spacing: 135 mm

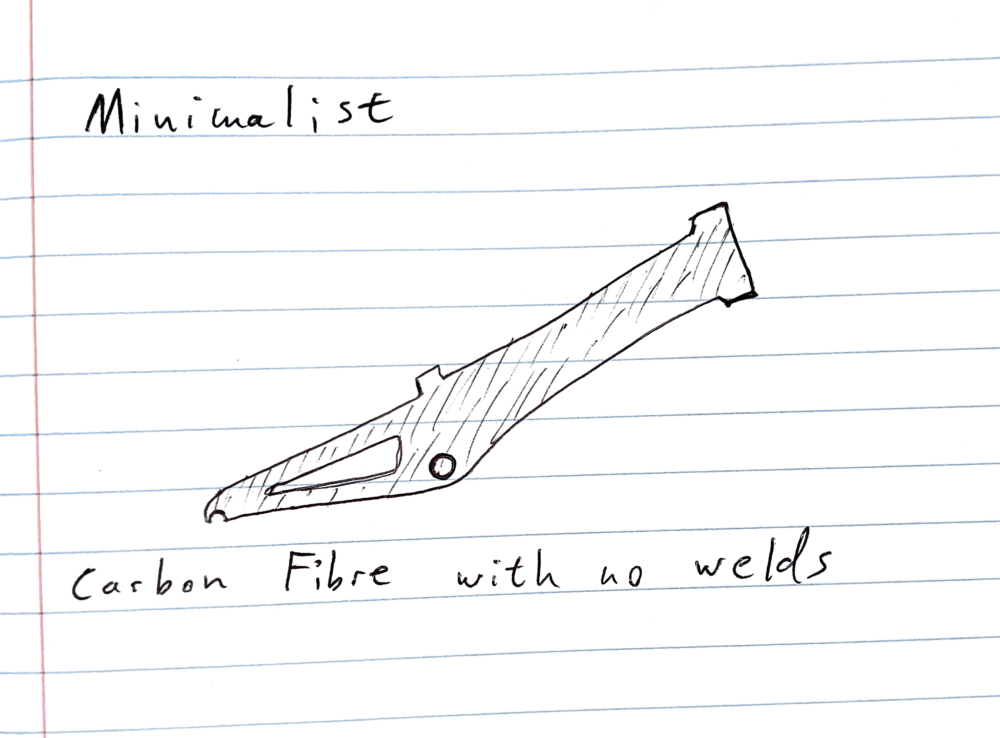

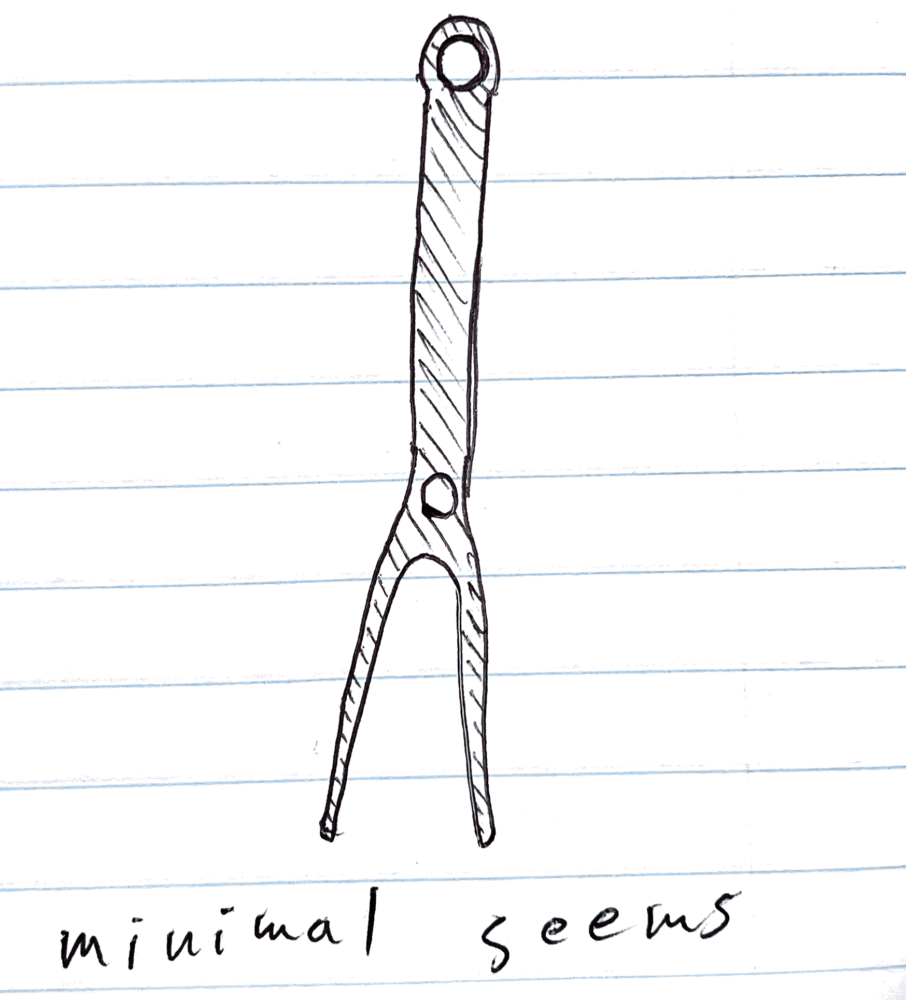

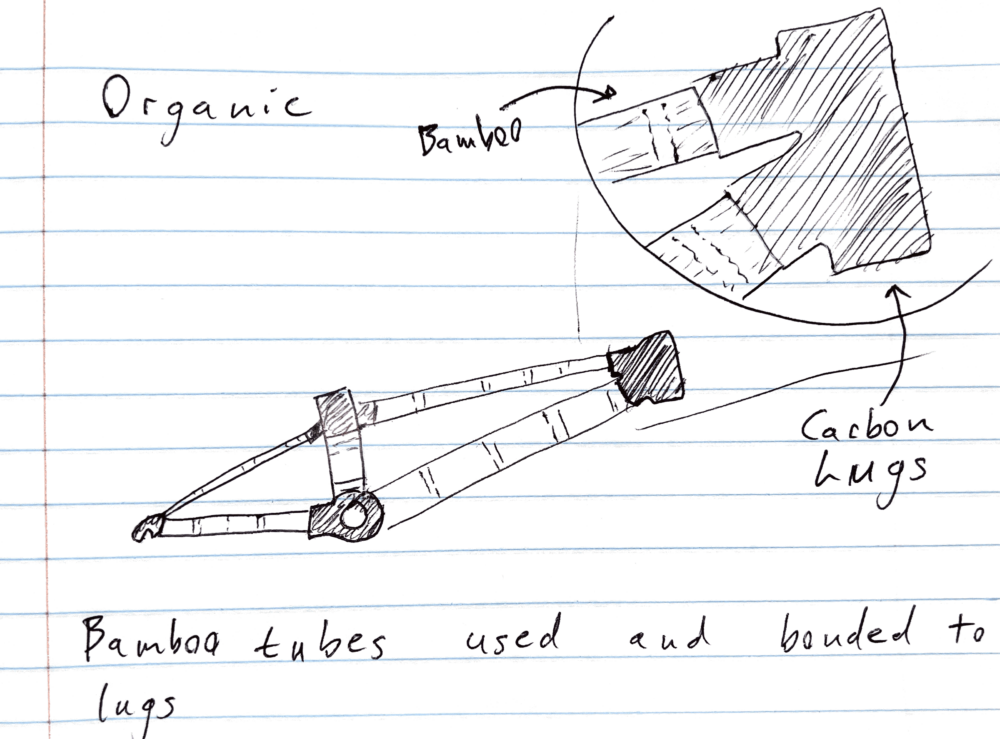

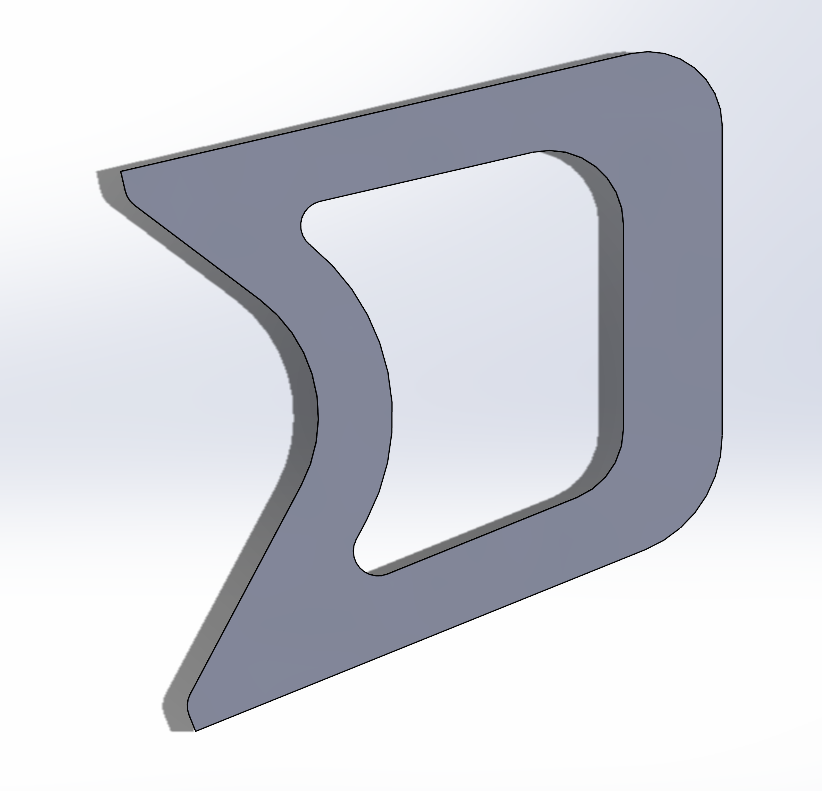

I also explored different aesthetics for this project if I were to choose something other than industrial. First I looked into an organic design, which I thought could be interesting because there are bike frames that are made out of bamboo. Second, I also looked at a minimalist aesthetic, this could be accomplished, by using carbon fiber to get rid of some of the extra lines and complexities that come with using steel tubing. Ultimately, I decided to stick with an industrial aesthetic mostly because steel would be the easiest to work with, and I am confident in my welding abilities when using steel.

Week 1 (March 18-22): At this point, I will potentially have time to start manufacturing the tubes and the frame components after having received the tubing and components required.

Week 2 (March 25-29): I will be unable to work on the project over spring break. I may have the time to start manufacturing the tubing on the last weekend.

Week 3 (April 1-5): This is when I will be able to complete the bending and general cutting of the tubes and begin setting up the frames jigging system. I will need to complete the rest of the coping and bending of the tubes and start putting all numbers in the frame jig system to be tack welding.

Week 4 (April 8-12): After tack welding, I will be able to finish weld the rest of the frame, and hopefully weld the head to gussets, brake, routing, and brake caliper mounts.

Week 5 (April 15-19): Finally, I will need to clearcoat the frame with linseed oil. I love it. This will leave the color of the steel and the welds exposed to maintain my industrial aesthetic. Furthermore, I will need to chase and face the bottom bracket and head tube of the bike so that they can interface with the high-tolerance components that fit in those areas. At this point, the frame should be done.

I am looking forward to seeing this project take shape and fulfill a dream that I have had for a long time. To make my own bike frame! I will begin manufacturing the materials and ordering external components for the frame shortly and I hope to have the complete bike at expo. I will continue to document the manufacturing process for you to see and share my progress. Please let me know if you have any questions and I hope you are also excited to see it come together!

Sources:

- https://www.webcyclery.com/product/inspired-hex-team-26-bike-14112.htm

- https://biketrialsdirect.com/2024-crewkerz-26-jealousy-ultimate-full-hs33/

2 Comments. Leave new

Hi Sophie!

Thanks for your response. I have definitely considered making the back out of steel as it could be more structurally sound. I even considered an industrial aesthetic for this project where the main structure would be steel instead of wood. Ultimately, I think that it may become more expensive for me to go in that direction but I am not opposed to having some steel elements in my minimalist design for structural integrity. Thank you for the feedback!

Hi Ian,

I really like the idea of furniture that also acts as a bike stand/ storage space as someone that also has limited space and a bike to store. Something that I was wondering while reading was if you had considered making the back stand piece out of steel (or other metal) square hollowed out support bars. I think the combination of metal and wood could go quite nicely and fit into the minimal aesthetic. I also would help from a structural standpoint if you are going to be trying to mount heavier kinds of bikes like mountain and trail bikes you mentioned.