Idea:

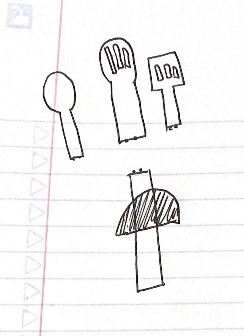

For my project, I imagine creating a multifunctional cooking tool similar to a spatula but with an interchangeable head, allowing users to switch between different attachments, like a spoon. This creative design provides convenience and adaptability in the kitchen, accommodating diverse cooking requirements with a single, versatile utensil. Additionally, drawing inspiration from the protective features of fencing swords, I want to integrate a hand guard that offers protection against splattering grease or hot liquids, emphasizing user safety during culinary activities.

I still haven’t decided between two potential aesthetic options: brutalist or rustic. Going for a brutalist approach would enable me to focus on the practical aspects of the design, emphasizing the rugged and utilitarian qualities of materials such as wood or plastic. This aesthetic would underscore the straightforward functionality of the interchangeable tops and hand protectors, resulting in a product that prioritizes functionality above all else. Conversely, embracing a rustic aesthetic would require greater attention to detail, encouraging a more elaborate and visually captivating design approach.

Rough sketch of product idea

Inspiration:

The inspiration behind my idea to develop a kitchen appliance with interchangeable top parts came from a need for convenience and versatility in when cooking. I thought of a scenario where I could simplify my kitchen tools by having just one base with interchangeable tops, allowing me to effortlessly switch between a spatula or spoon attachment depending on what was needed. This concept not only offered practicality but also addressed the issue of wear and tear on kitchen utensils. By having replaceable tops, I could easily swap out a damaged or worn component without the need to replace the entire utensil, thereby extending its lifespan and reducing waste.

In addition, the idea of incorporating a grease cover into the design was born out of a firsthand experience while cooking. During my first attempts at frying, I was concerned about the potential hazards of splattering grease. This sparked the idea of the need for additional safety measures in the kitchen. By integrating a protective shield into the appliance, the goal is to reduce the risks associated with cooking with hot oil or boiling water, offering users a safer and more comfortable cooking experience. This dual functionality not only enhances user safety but also adds a practical dimension to the appliance, making it an indispensable tool for home cooks and chefs alike.

Inspiration for grease cover [1]

Timeframe:

The project’s timeline spans from March 10 to April 20, with different phases dedicated to specific aspects of development. From March 10 to March 23, the focus lies on finalizing renders of the kitchen appliance. During this period, I will model and design the different elements and components of the final product, ensuring that the models accurately reflect the envisioned product.

Moving into the next phase from April 2 to April 7, the emphasis shifts to practical implementation with 3D printing and iteration testing. I will try to produce multiple prototypes, allowing for hands-on exploration and evaluation of various design iterations. This iterative process will allow me to identify strengths and weaknesses in the design, helping me to refine and improve the final product. From April 7 to April 20, the project would enter its final phase, dedicated to enhancing the design and perfecting the aesthetic look, ensuring that the end product not only meets but exceeds expectations in both form and function.

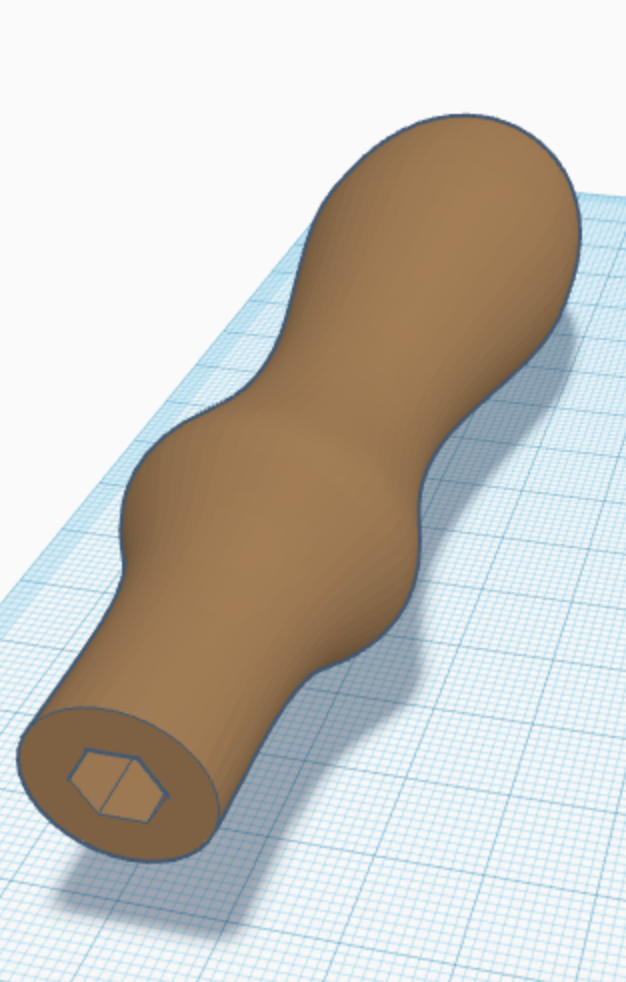

Render of the base without the grease cover

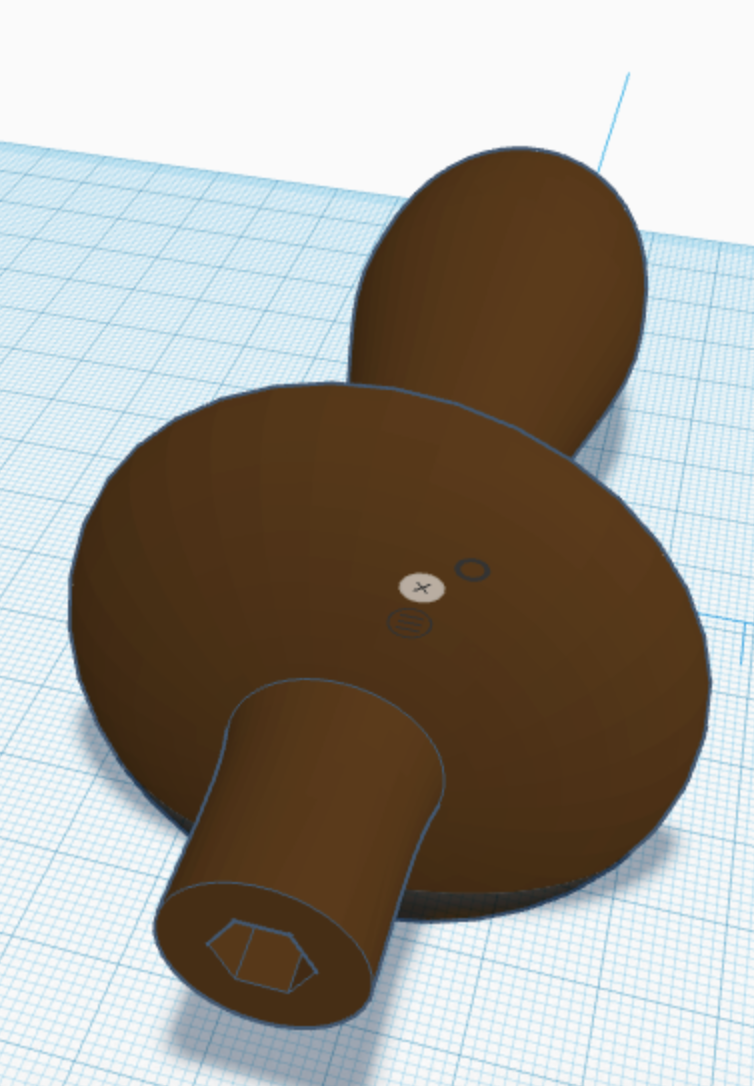

Render of the base with the grease cover

Construction:

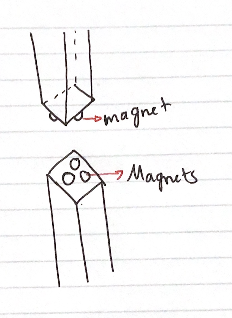

The construction of the final project will involve a combination of 3D printing and manual assembly techniques. The base and potentially the tops will be fabricated using 3D printing technology, allowing for precise customization and rapid prototyping. Magnets will be fixed to both the base and the tops, simplifying the detachment and interchangeability. This magnetic mechanism will serve as a secure and easy attachment, allowing users to switch between different utensil attachments. As for the grease cover, I haven’t yet decided on the construction method; it may involve either 3D printing or manual fabrication using cut plastic. This choice will depend on factors such as material availability and suitability for the desired functionality.

Once the prototype is assembled, I will then try enhancing its aesthetic appeal and coherence with the chosen design direction. Whether embracing a brutalist or rustic aesthetic, different elements will be designed or changed to fit with the aesthetic, as well as providing a harmonious integration of style and functionality. If I still have time, I will refine the final product to improve its looks or its durability.

Sketch of joining mechanism

References:

[1] “Amazon.” Practice Fencing Epee with French Handle, www.amazon.com/Fencing-epees/b?ie=UTF8&node=13287001. Accessed 5 Mar. 2024.

1 Comment. Leave new

Hi Ari,

I like the idea of a multi functional utensil for the kitchen. I think the use of magnets is a good one depending on how you are looking on implementing it into your design. You might also consider having the handle be something for the attachable part to fit around for extra security.

Also a few questions that I had while reading was what material you were going to use for the 3D printer? Because if you were planing on using PLA (probably the one that will be most commonly available in the workspaces) it has quite a low melting point so will probably melt if one were actually cook with it. Wood, silicone or stainless steal could be an alternative option they are commonly used when cooking and if you went with wood it could match your rustic aesthetic or stainless steel to the brutalist aesthetic. Then the other question I had was if the hand cover was going to be removable?