Collecting Materials

There are two types of materials I am collecting: tools and consumables. In the realm of tools, I am collecting glass cutters, glass cutting oil, specialized pliers, X-acto knives, and a soldering iron. In terms of consumables, I am collecting tape, used stained glass, cardboard, copper tape, and 1lb of solder. All of the tools, the copper tape, and the solder are being sourced from Amazon. The cardboard and tape are from my supply and recycling. The used stained glass was sourced from Art Parts, a store for excess or pre-used art supplies. I gathered 6 lbs of gray stained glass and 2 lbs of off-white stained glass. For the sake of my wallet, I didn’t get a water sander which is used to perfect and remove sharp edges from the cut glass.

Mock-up

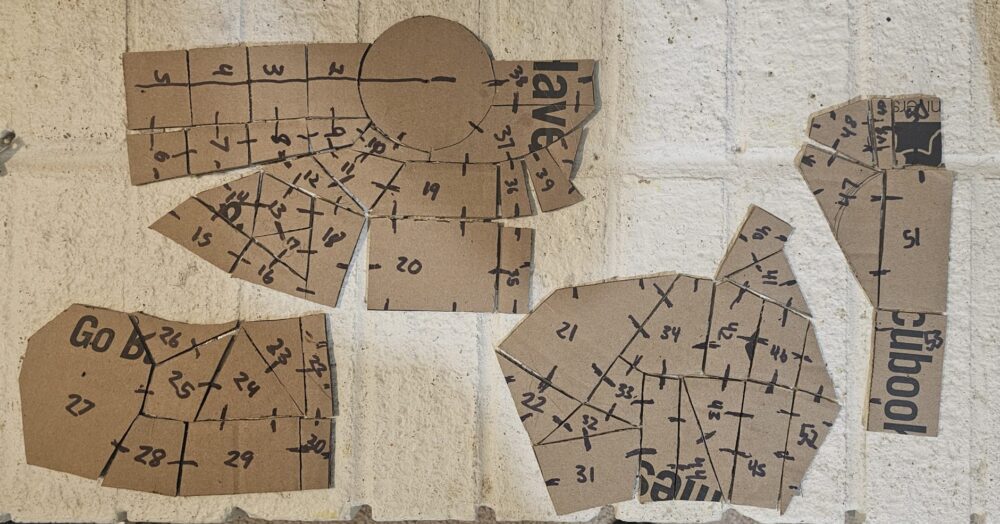

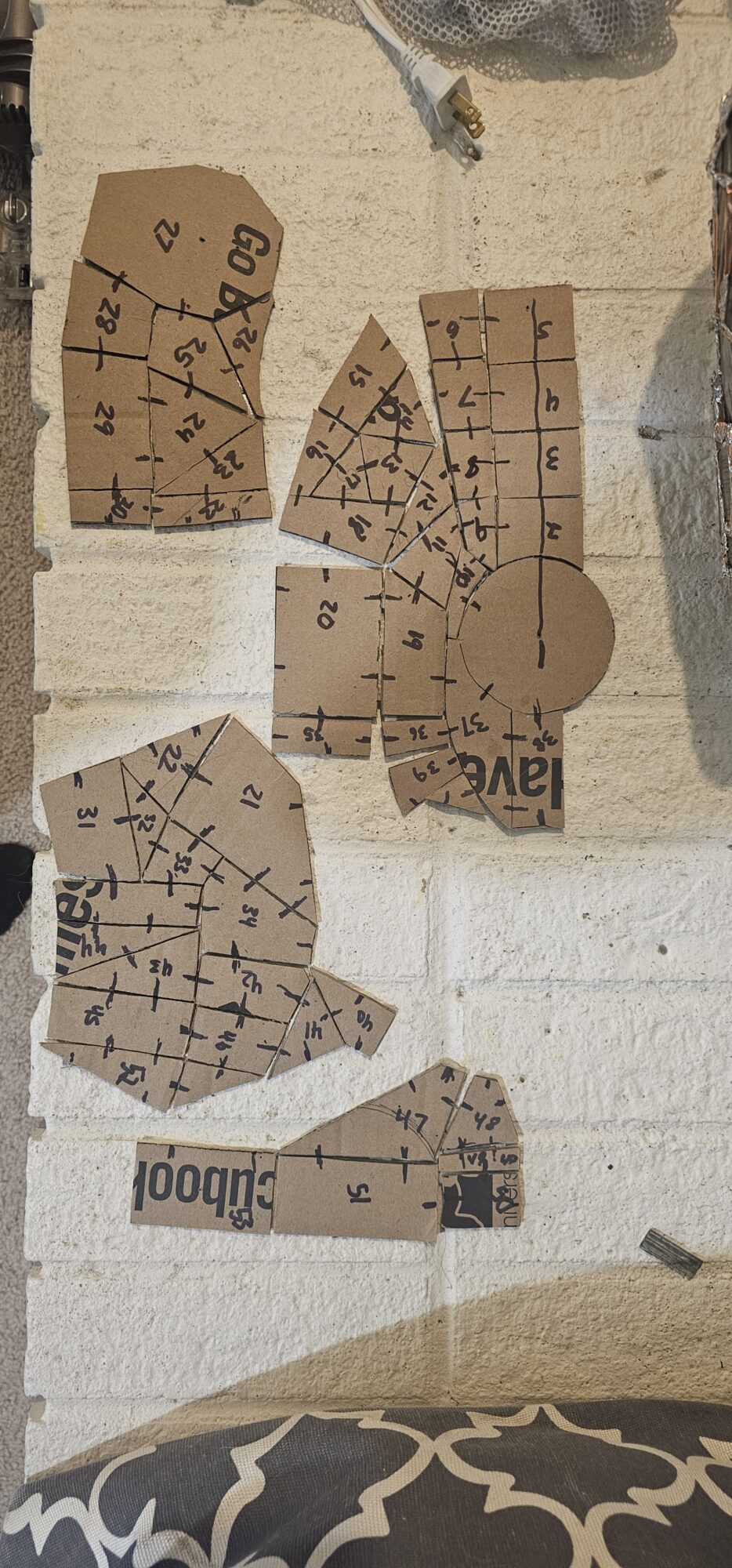

To begin this project, I wanted to mock up the design to know what I would need to cut from the glass or if this project was even attainable. To do this I used a foam head from previous projects and several hats to make the head the same circumference as mine. I completed the mock-up using recycled cardboard as it has a similar thickness to the glass I’ll be using.

Starting from the top of the head I slowly worked outwards creating the shape of the helmet with pieces of cardboard and holding it together with tape. I used a straightedge and a sharpie to trace the pieces I wanted to cut and used an X-acto knife to get clean and sharp cuts.

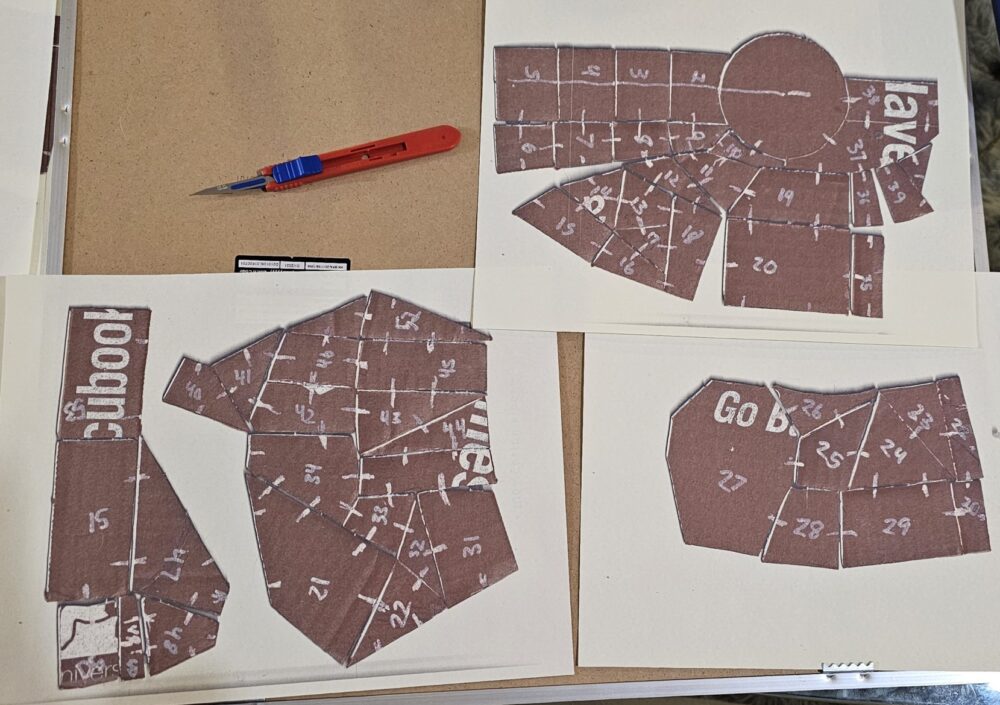

Once I had fully mocked the helmet, I labeled half of the pieces with part numbers and scanned them using my printer. This created 1:1 scale paper templates that I cut out using an X-acto knife. These templates will be used to outline all of the cuts I will need to make on the glass. I only printed one template because all of the pieces except the center pieces are mirror images meaning I would just have to use the reverse of the templates.

Future Fabrication

As far as a fabrication timeline, I have done all of the work I can without my Amazon order. Unfortunately, It seems the order will not get here until a week before the project comes to a close. This puts a very tight turnaround time from my mock-up to my finished product. Because this is my first time working with stained glass, I anticipate that my project will be finished by the last day of presentations.

Self-Education

Until the Amazon shipment arrives I will continue to educate myself with tutorials in order to give myself the best chances in fabrication time. Thus far I have learned the overall techniques for soldering flat stained glass and some for soldering stained glass sculptures. The concept of soldering stained glass is incredibly similar to welding. A few “tacks” are placed to secure the stained glass before a bead of solder is applied to add structural integrity and a smooth finished look.

2 Comments. Leave new

Hi Jess, super ambitious project, im excited to see how it is going to turn out. Great work so far! how do you plan on cutting the stained glass?

Hi Jess,

Very clever idea to scan the parts with your printer! Have you ever used a laser cutter? Could have been an effective way to avoid the x-acto knife, but then again, maybe you wanted the knife to play into the aesthetic!