This year’s third post. Students were asked “What progress have you made on your Upcycle project? Show your plans. What does your fabrication schedule look like? What materials have you collected?”

Project Refresh

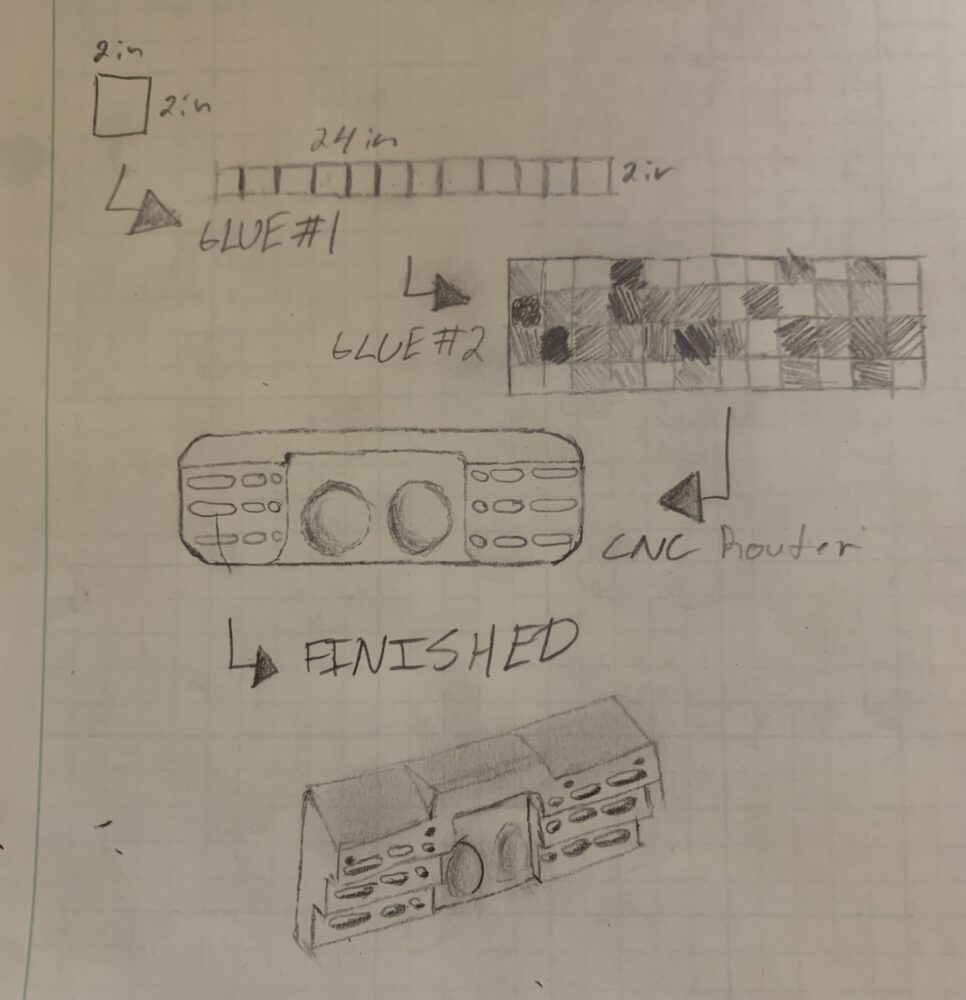

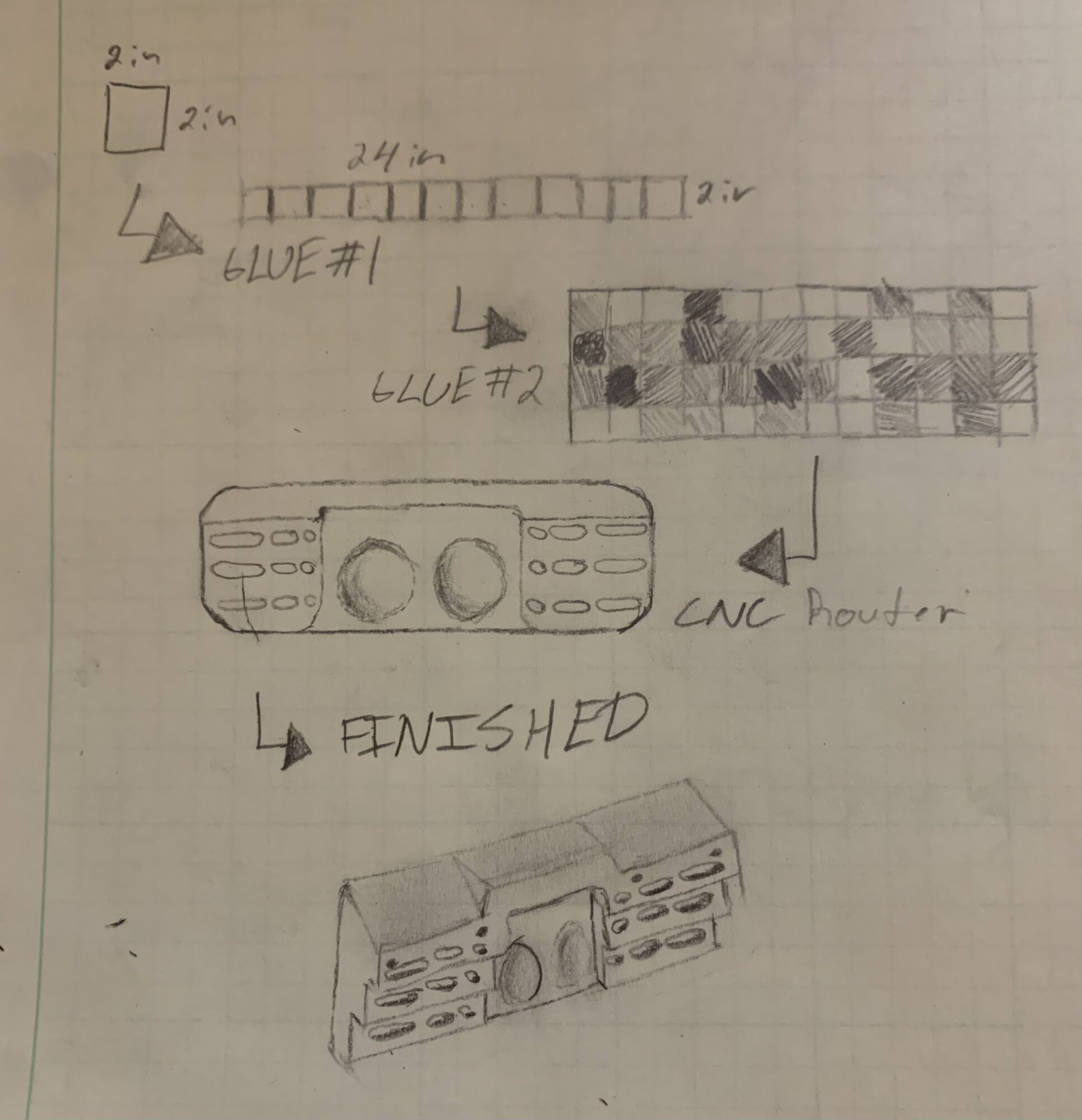

From my last posts, I am continuing with the idea of a patchwork hangboard. I am designing the hangboard as training device for rock climbing, but would like to do so following the patchwork aesthetic. This will include gathering scrap pieces of wood from various places, gluing it together, CNC routing it, and finally sanding and finishing the project.

Project Plans

The manufacturing work which will be required by this project includes the following steps:

- Gluing

- Gluing again

- CNC routing

- Polishing and finishing

The design flow above demonstrates the different stages which the hangboard will go through. The most time consuming aspects will be the glue ups of the wood, mainly due to the fact that they require waiting overnight in order to properly bond. As demonstrated as well, all of the squares are anticipated to be the same size which helps ensure the glue up goes as smooth as possible.

Materials Sourcing

Currently I have no material in my possession, however, both the ideaforge and ITLL woodshops have plenty of extra wood which I am able to use for this project.

Timeline

Thursday February 7th:

- Contact additional wood shops, suppliers, etc to gain insight into sourcing material

Friday February 8th – Sunday February 10th

- Gather materials from ITLL, Ideaforge, and other locations

Monday February 11th

- Cut down all wood pieces to a uniform sizing to allow for the patchwork creation

Tuesday February 12th

- Assemble the wood into glue up position number 1 and allow to bond overnight

Wednesday February 13th

- Assemble the wood into glue up position number 2 and allow to bond overnight

Thursday February 14th

- Bring the solid piece of patchwork wood into the ITLL for CNC Routing

Friday February 15th

- Using either the ITLL or Ideaforge woodshop, perform finishing work on the hangboard

- This includes sanding, fixing imperfections, and applying a finish to it

Saturday February 16th to Wednesday February 20th

- Extra time for when something goes wrong

Closing Remarks

Overall, I still have a lot of work to do, however, I have a solid plan in place to make significant progress on the design during the next few days and next week. I am excited to see how it turns out!

4 Comments. Leave new

Hey Ian!

This looks really interesting. I think your project is sort of similar to mine in that we’re both using reclaimed/scrap wood, but for very different projects, so it was fun to read how yours was different from mine! Definitely wonder how ours are going to differ in their final appearance due to the differences in scrap material that we end up using, but also if they’ll look similar at all since they’ll both be a patchwork-style construction. I do really like your extra time portion for when things go wrong. Definitely something I wish more people (engineers specifically, hooooly crap) incorporated into their projects. How did you decide which glue you’re going to use? Or is that something you’re still working on? Looking forward to seeing what things look like!

Josh

Hey Josh, good to hear from you! I haven’t decided on the glue yet, standard wood glue I’d imagine though? Also, funny you mention the extra time I’ve allotted because it is definitely necessary. I may end up needing to modify my project so stay tuned!

Hi Ian!

This is looking like it will be an awesome project! I enjoy rock climbing myself and I think that the scope of this project will resonate with a lot of the students in this class. The patchwork aesthetic is a really interesting choice that will be unique compared to other hang boards I have seen and there should be plenty of scrap wood around campus for you to use. The use of a CNC router will be an interesting challenge and I’m sure will result in an excellent finished product. Have you ever had experience with CNC programming or do you have a plan of how to set up the machine for this project? I look forward to seeing what you are able to accomplish in this project!

Hi Ian, thanks for your comment! I have actually used CNC machines before. Additionally in the ITLL they help you out throughout the entire process regardless of the experience you have if you ever need to use it. Unfortunately, I did run into some issues sourcing scrap wood which may require a project modification. We will just have to see where it goes!