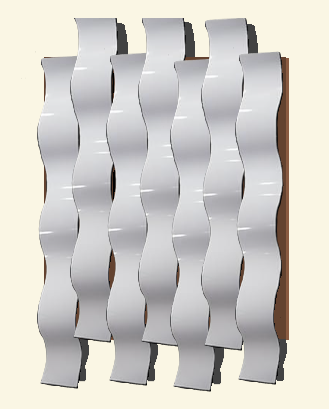

Sketch of wall sculpture

I am still planning on creating a metallic wall sculpture using aluminum cans as my primary source of material. I plan to build something similar to the sketch shown above. I estimate that I’ll need around 30 cans to complete the wall sculpture. I want my decoration to be a decent size on my wall so I am planning on making it 28″ x 21″. I have yet to find a material to use for the frame but I think that wood or metal (if I can find some) would work well.

Cut aluminum cans

I have begun collecting and cutting the aluminum cans into aluminum sheets. The aluminum sheets measure roughly 7″ x 3″. I may need to refine my cutting process or deburr the edges of the sheets because the edges are very sharp and jagged.

Epoxy on hand

In order to bond multiple aluminum sheets together and to the frame I will be using Gorilla epoxy. Gorilla epoxy is the only epoxy that I currently have on hand so I will need to be conservative in its use to make sure that I do not run out.

References:

https://www.lowes.com/pd/Gorilla-Epoxy-Clear-Epoxy-Adhesive/5002785627

5 Comments. Leave new

[…] Post #3 – Upcycling Update […]

Hi Alex,

I love the sketch and the idea and I think you will make something that is very beautiful. I was wondering if you had an idea of how to smooth the metal to remove creases. If that is something too difficult to accomplish I was even thinking of leaning into the folds and making it apart of the piece.

I originally planned to try to roll the creases out as best I can but I like the idea of keeping the imperfections in the sheets if the rolling method is not effective.

I really like your sketch of your planned wall sculpture. Despite being only made of foil, the design is really interesting thanks to the intricate form. How do you plan to bend the foil into forms you planned for?

I planned to get the thin aluminum sheets to the correct shape using the mounting positions on the base and the sheets natural flexibility.