In Part 1, I explored the inspirations, vision, and design process behind the Interactive Geometric Rock project. Now, in Part 2, let’s dive into the ‘how’ of the project, discussing the manufacturing process, challenges encountered, and the final outcome. Additionally, I will cover the experimentation with light panel prototypes and the use of wooden filament for the rock’s structure, as well as provide a project timeline.

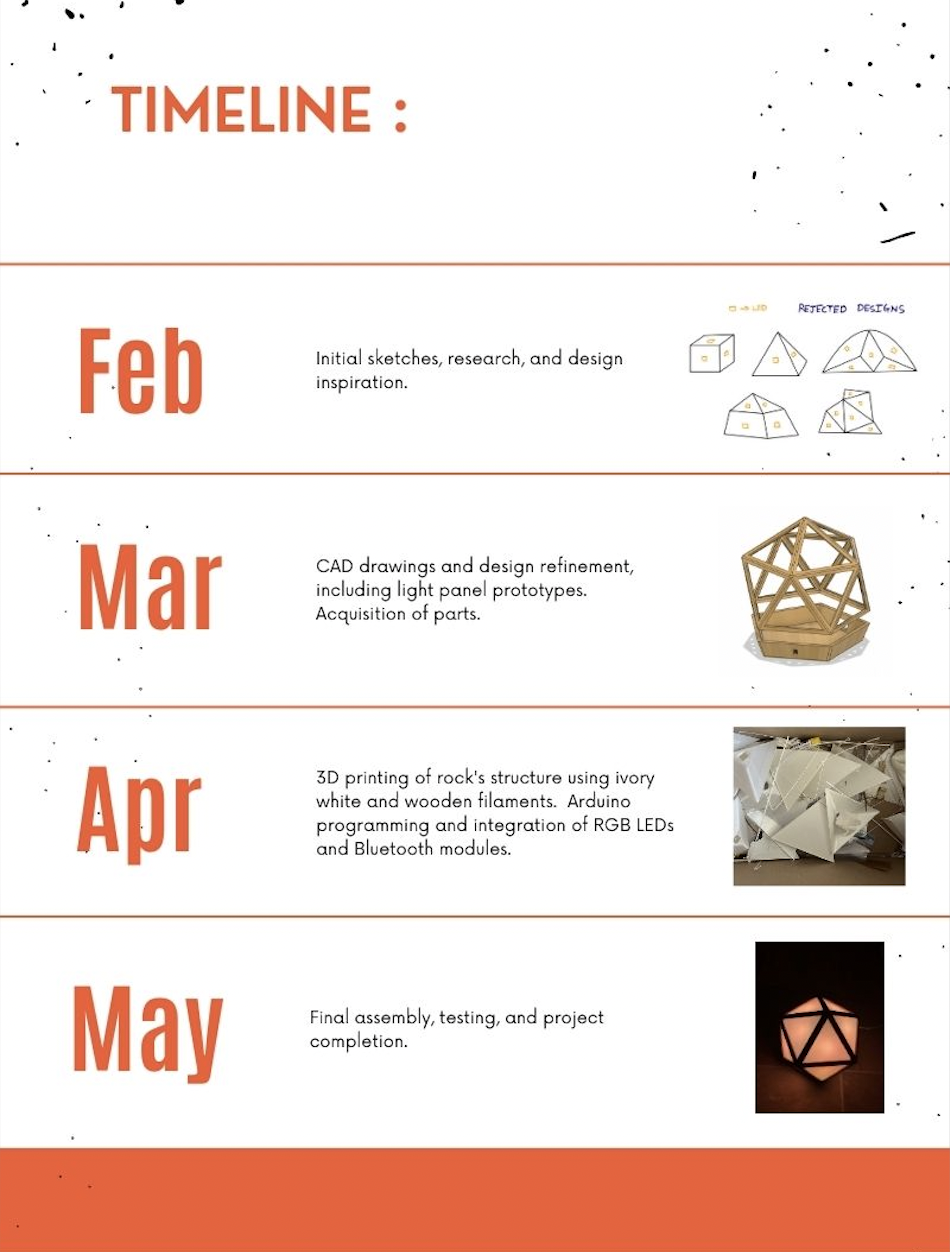

The timeline for my project is as follows –

The intricate fabrication process commenced with the creation of the light panels, which were designed to seamlessly integrate into the external rock structure. Utilizing 3D printing, seven distinct prototypes were developed before finalizing the optimal light panel design. To achieve the desired frosted surface on the light panel, a custom 3D printed bed was also manufactured.

Careful attention was given to the light panel thickness and the distance between the LED and the screen, as these factors were crucial for delivering an exceptional lighting experience. For the external structure, wooden filament was employed in the 3D printing process to impart a natural aesthetic that enhanced the overall visual appeal.

The Arduino IDE platform facilitated the coding process, enabling wireless control of the rock structure. NEOPixel LEDs were utilized, allowing for precise control of each individual panel. The assembly process was completed by securely adhering the light panels to the outer rock structure using a strong superglue, ensuring a durable and cohesive final product.

In conclusion, the journey from initial plans to the final product has been a fulfilling and enlightening experience. The initial vision aimed to blend technology and natural aesthetics to create a captivating, illuminated rock structure that would both intrigue and delight. Through perseverance, experimentation, and learning from various prototypes, I successfully crafted a seamless fusion of the natural and the technological, achieving our desired aesthetic goals.

While the final product showcases the intended natural aesthetics, reflecting on the process reveals opportunities for improvement. In retrospect, a more in-depth exploration of materials and finishes could have further enhanced the overall appearance. Additionally, more emphasis on the integration of organic forms into the design might have resulted in a more harmonious marriage between nature and technology.

Link for the final presentation :-