Since the Design Preview of my project of building a wristwatch inspired by Art Nouveau and Clockpunk aesthetics. There have been a few developments. I have continued my research on learning how to build a wristwatch, and also what parts I should get to accomplish it.

I have ordered the ST3600k movement, a brass PVD coated watch case, embossed leather band, and designer watch hands.

But the brass pvd watch case is suddenly showing massive delays in delivery and might not be delivered in time for the completion of this project, so as a backup, I have ordered a simple black watch case and embossed leather bands to suit it as well. They are shown here:

Also, I couldn’t find a dial for the watch that which would be minimally obstructive yet suit the Art Nouveau aesthetic. Due to this, I had decided to build my own dial out of metallic vinyl, as it would satisfy the space requirement due to how thin vinyl are and also suit the aesthetic.

The creation of the dial can be broken down into 4 parts:

- Looking for the best available materials:

I was already able to finalize metallic vinyl as the base material for the dial due to its low thickness, but just the vinyl would not have been very ornamental. So I decided to adorn it with small blue gems as well to complement the copper color.

I was able to find metallic vinyl at Joann and found small blue gems of sizes ss6, ss8, ss10 at Michaels.

2. Designing the dial:

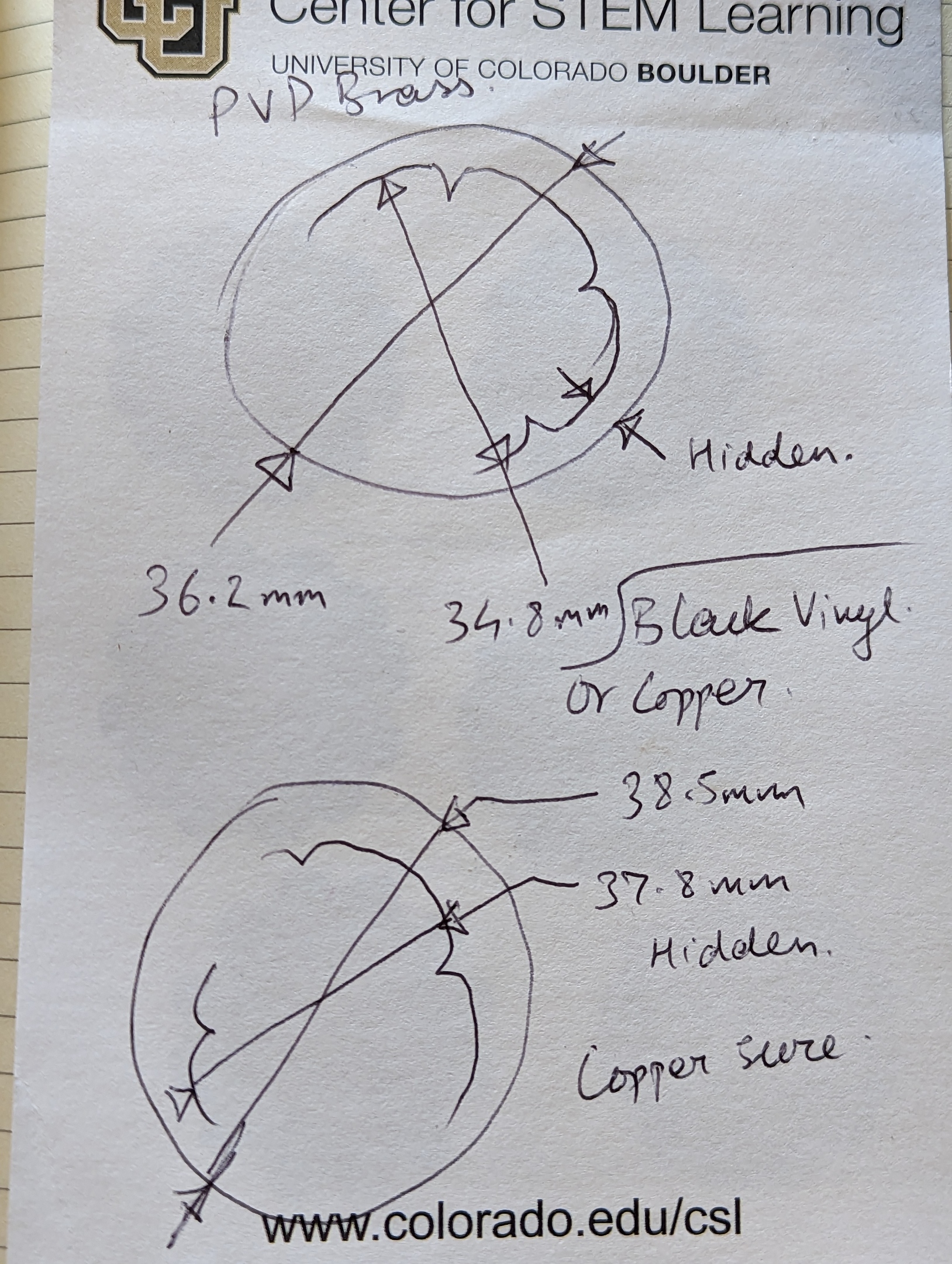

First I started with measurements and constraints for the design.

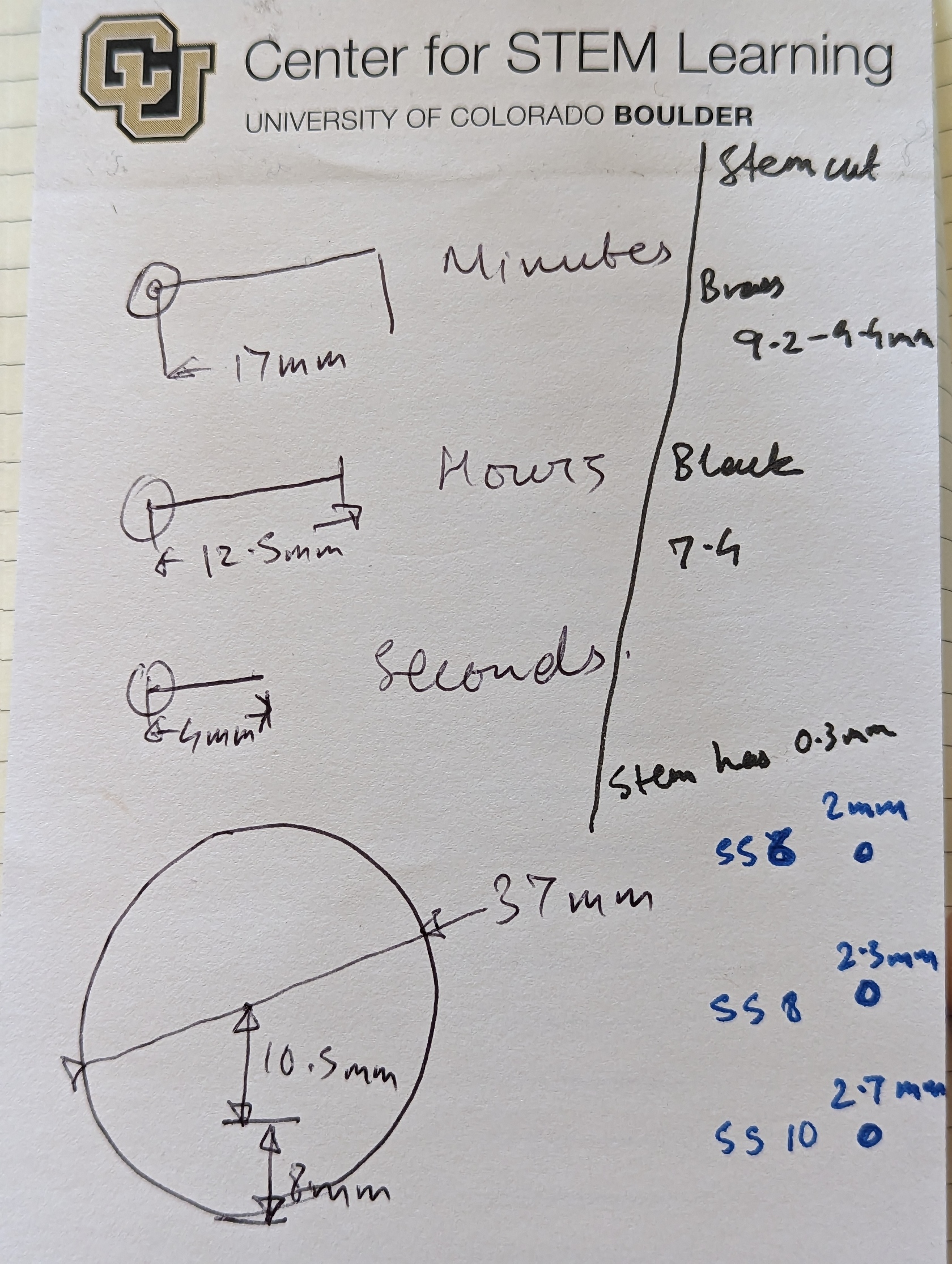

The available space for a dial inside a mechanical watch is generally between 0.2mm to 0.4mm. The thickness of the metallic vinyl is 0.1mm and would thus suit the purpose.

Next, the gem sizes of ss6, ss8, and ss10 had an approximate diameter of 2mm, 2.3mm and 2.7mm.

Then I measured the watch hands to determine what should be the inner diameter of the ring dial.

The watch hands of hour, minutes and seconds had radial length of 12.5mm, 17mm, and 4mm.

The outer diameter of the ring diameter would be determined by the inner size of the case where the dial would be installed, it was 36.2mm for the originally ordered watch case and 38.5mm for the backup black watch case.

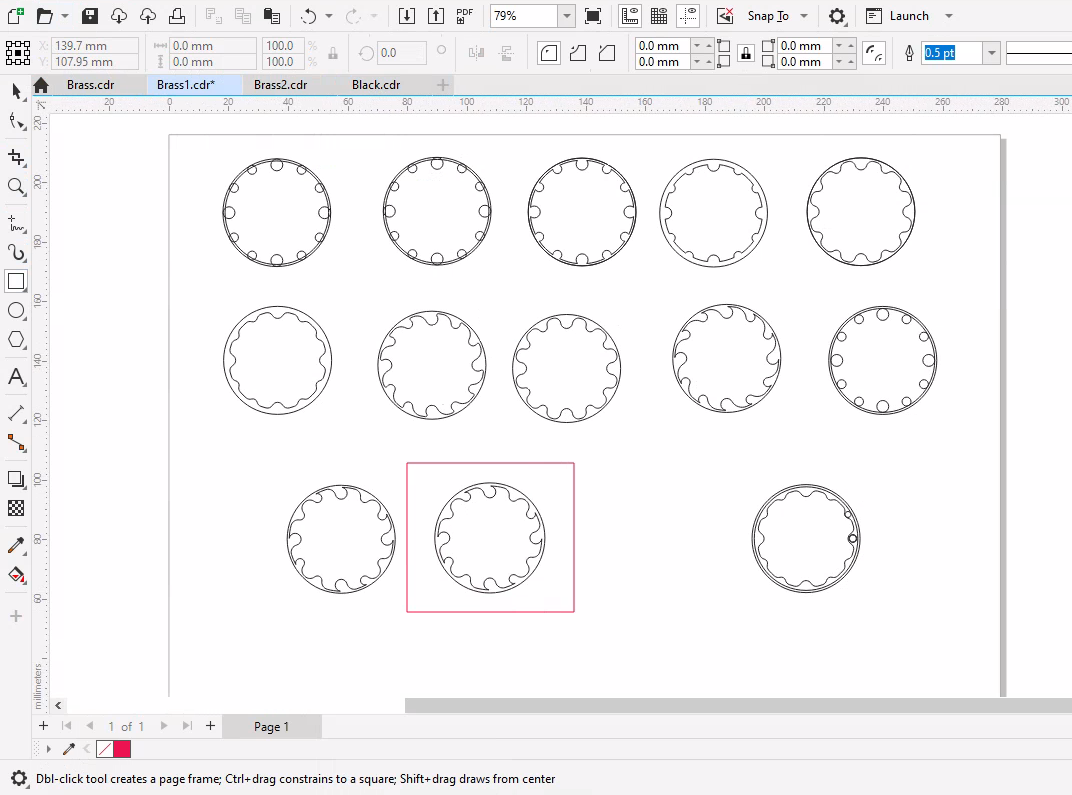

On to creating the CAD for the cutting. I had to use CorelDraw as it is available through the University OIT and a vector file is needed for the vinyl cutting software. I referred to a lot of tutorials for CorelDraw as I didn’t knew how to use a software and couldn’t properly perform simplest functions like how to do fillet at corners. My referred youtube videos are in the references.

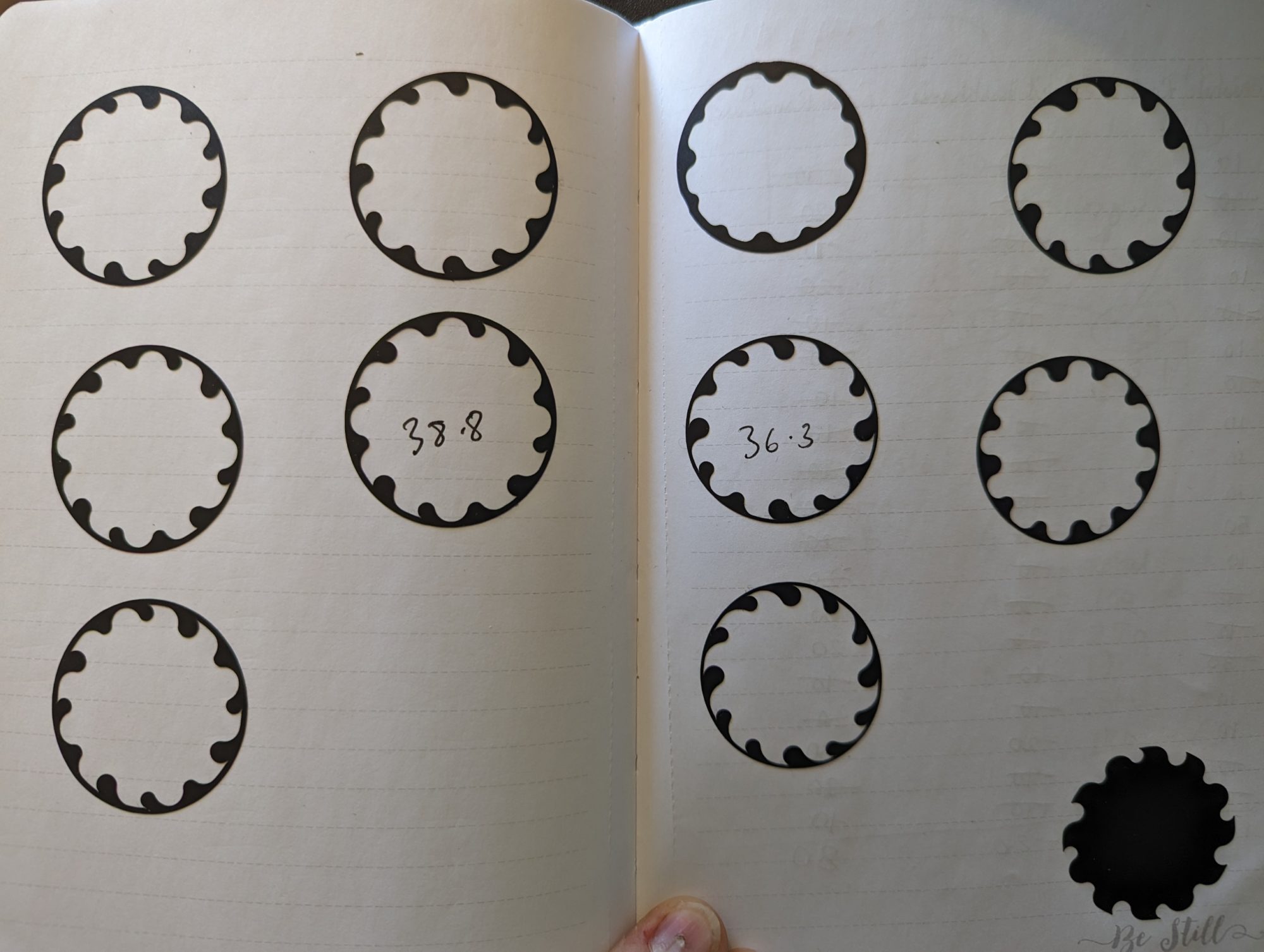

I went through iterations of the design where I also had to change the sizes to fit the watch case snuggly. I was dry fitting different sizes of a black vinyl which was used for testing.

The 12, 3, 6, 9 hour markers were going to be of the ss10 gems while the other 8 would be of ss6 gems, so each had different size. I finalized on the dial design that was asymmetric and looked unique.

3. Cutting the dial

After finalizing the dial design after test, I had to take some quick tutorials on how to use a Roland GS 24 vinyl cutting machine and using the CutStudio for it. The university provided resources were referred for this as well as a couple of youtube video tutorials.

Here are the final vinyl cuts.

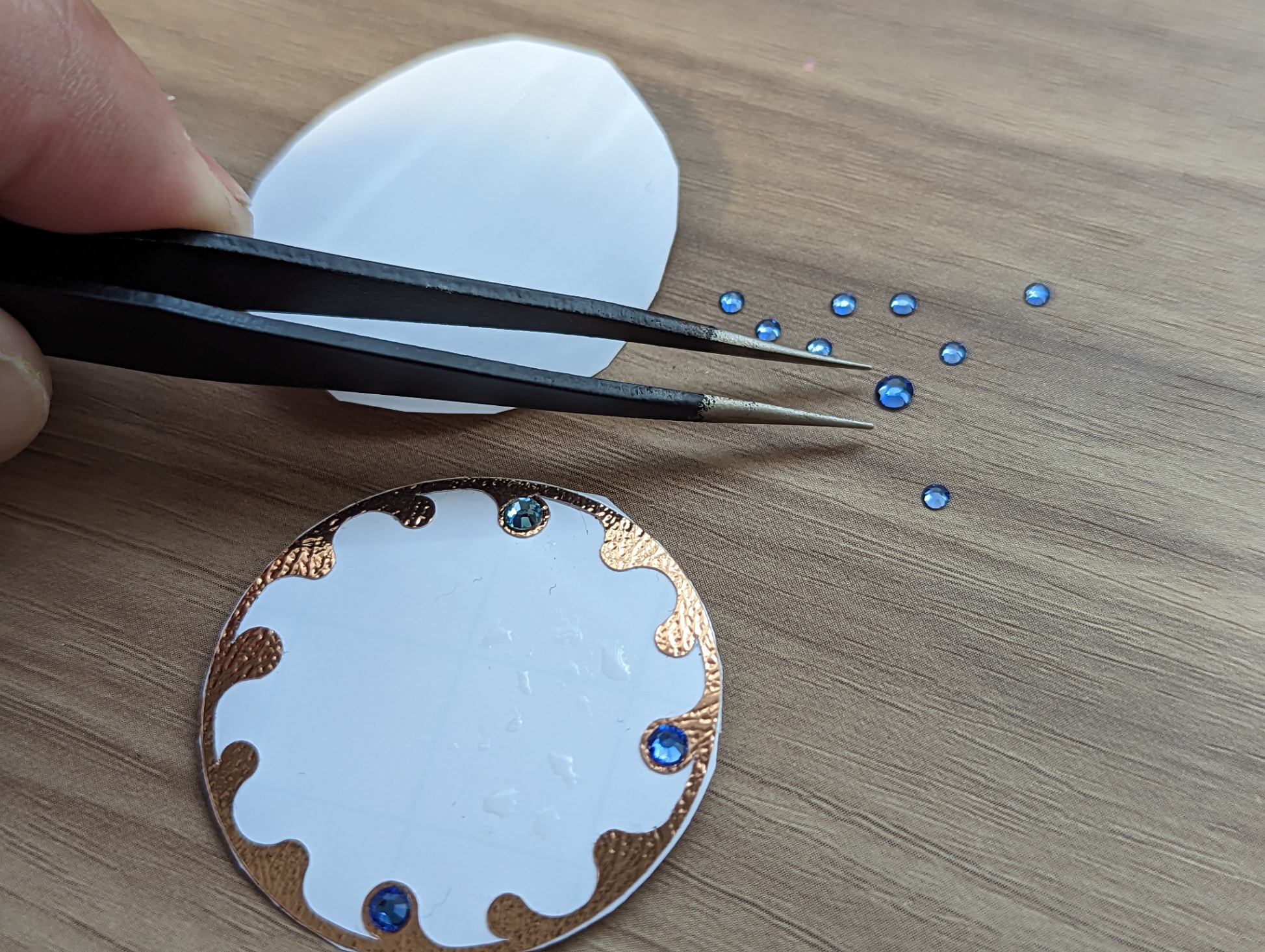

4. Assembling the dial

After having the vinyl cuts, watch building toolkit, and gems in hand, I started to stick the gems on the dial using tweezers and a minute dab of superglue. I intentionally kept the color of the 12 hour marker different to provide significance and directionality while installing.

I have also checked the compatibility of the parts I have received and haven’t found any discrepancies yet.

References

Coreldraw and Vinyl cutting

- https://www.youtube.com/watch?v=d-BV4BZf1ZA

- https://www.youtube.com/watch?v=6Sq29e1dBYs

- https://www.youtube.com/watch?v=2U_7KhmTBDI

- https://www.youtube.com/watch?v=-7Dk_n6XhfI

- https://www.youtube.com/watch?v=1XpimtOTiik

- https://www.youtube.com/watch?v=eNyuAu7OGhc

- https://www.youtube.com/watch?v=vIW1wwvdYf8

- https://www.youtube.com/watch?v=nF8gr9VNdrw

- https://www.youtube.com/watch?v=Vu29KeLVDD0

2 Comments. Leave new

Your final project progress is so intricate and beautiful just as your intended product aesthetics. Hands down, my personal fav project among others. Also, I would like to place a custom watch order, pls? Haha!

It seems that you’ve made quite a lot of progress on your watch! It’s looking great so far, and I love how you’ve thoroughly documented your construction process. Best of luck on the rest of your project!