.

This project has had some rather severe turns and changes throughout the semester. I originally planned to make myself a pair of moccasins, but found that I had very little I was considering for that project as far as an aesthetic vision of any kind. To allow myself to consider the aesthetics rather than prioritizing function and availability of raw materials, I shifted to a project in line with my hobby as a gunsmith. I have been working for the past few semesters to rebuild an old rifle for myself, something I could use primarily for hunting. A feature of rifles that is often implemented to reduce random variability in precision is a free-floating barrel, which allows the barrel to oscillate similarly to a cantilevered beam. This could then be tuned to place a node at the end, greatly increasing precision. The rifle I have been working on mounts the front sight directly to the barrel as well as the receiver, forcing a node to be at that front sight block. My solution for this is to make a custom foregrip that allows the barrel to free float, but still connects to the receiver portion that runs above the barrel.

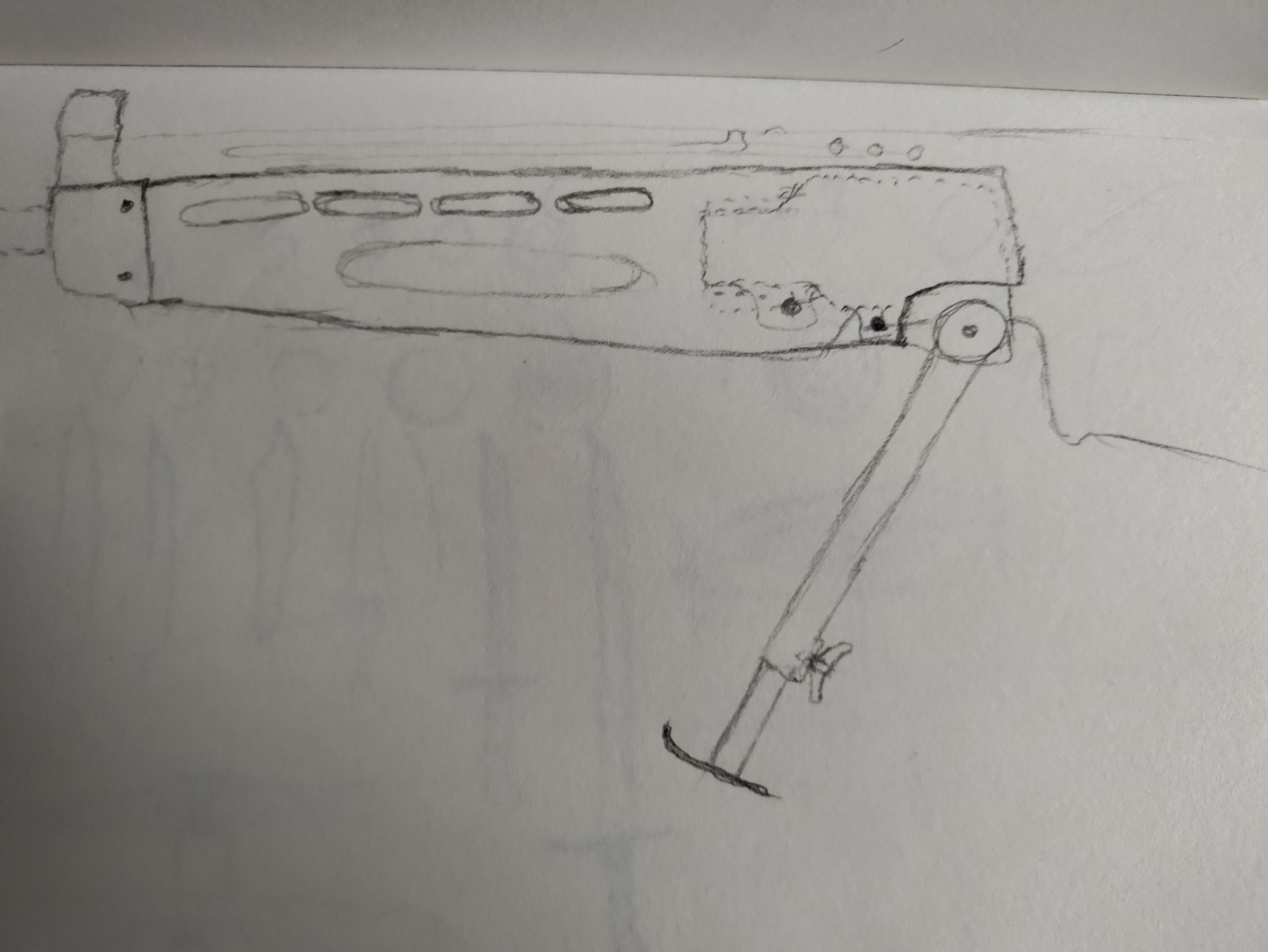

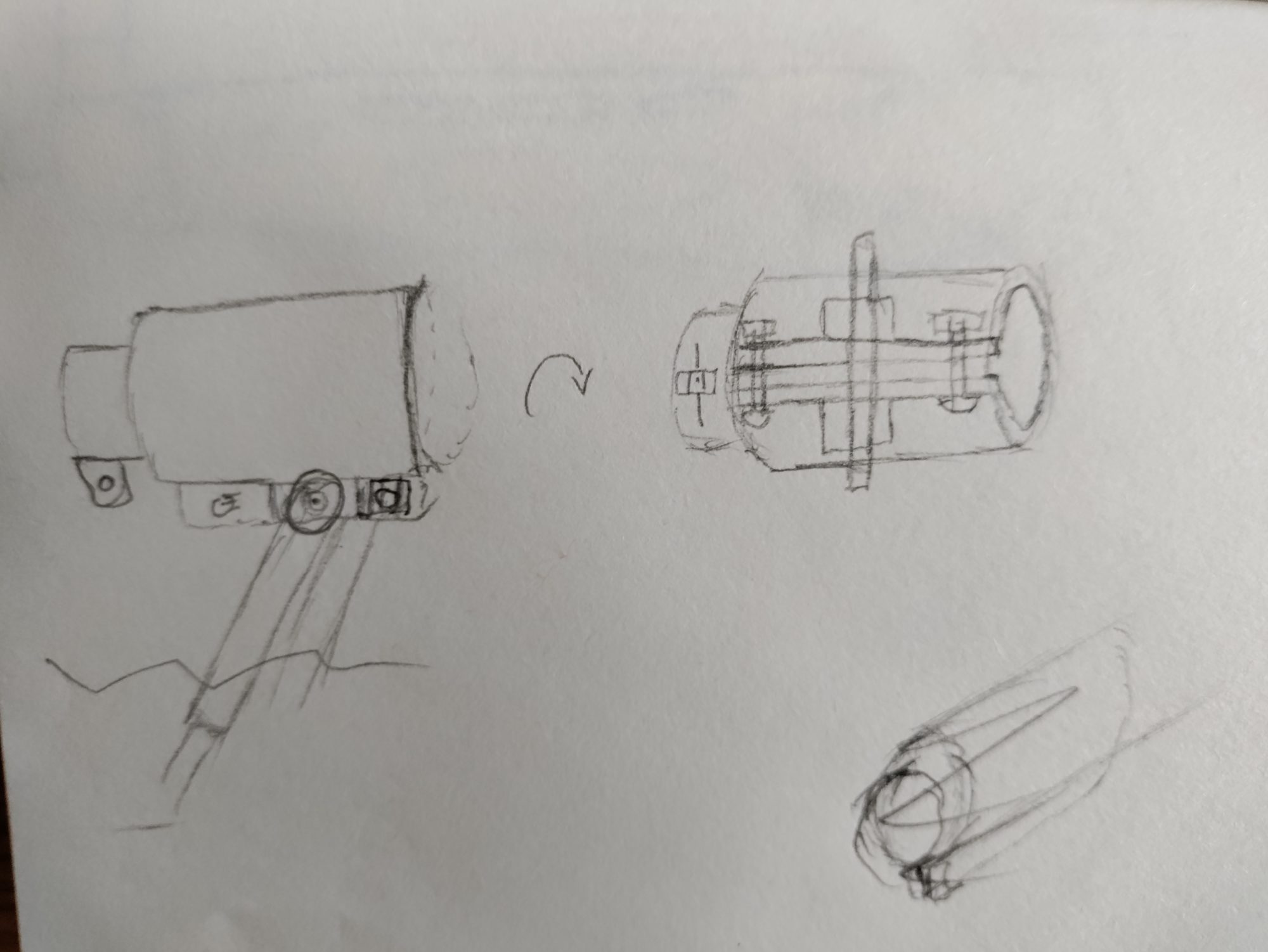

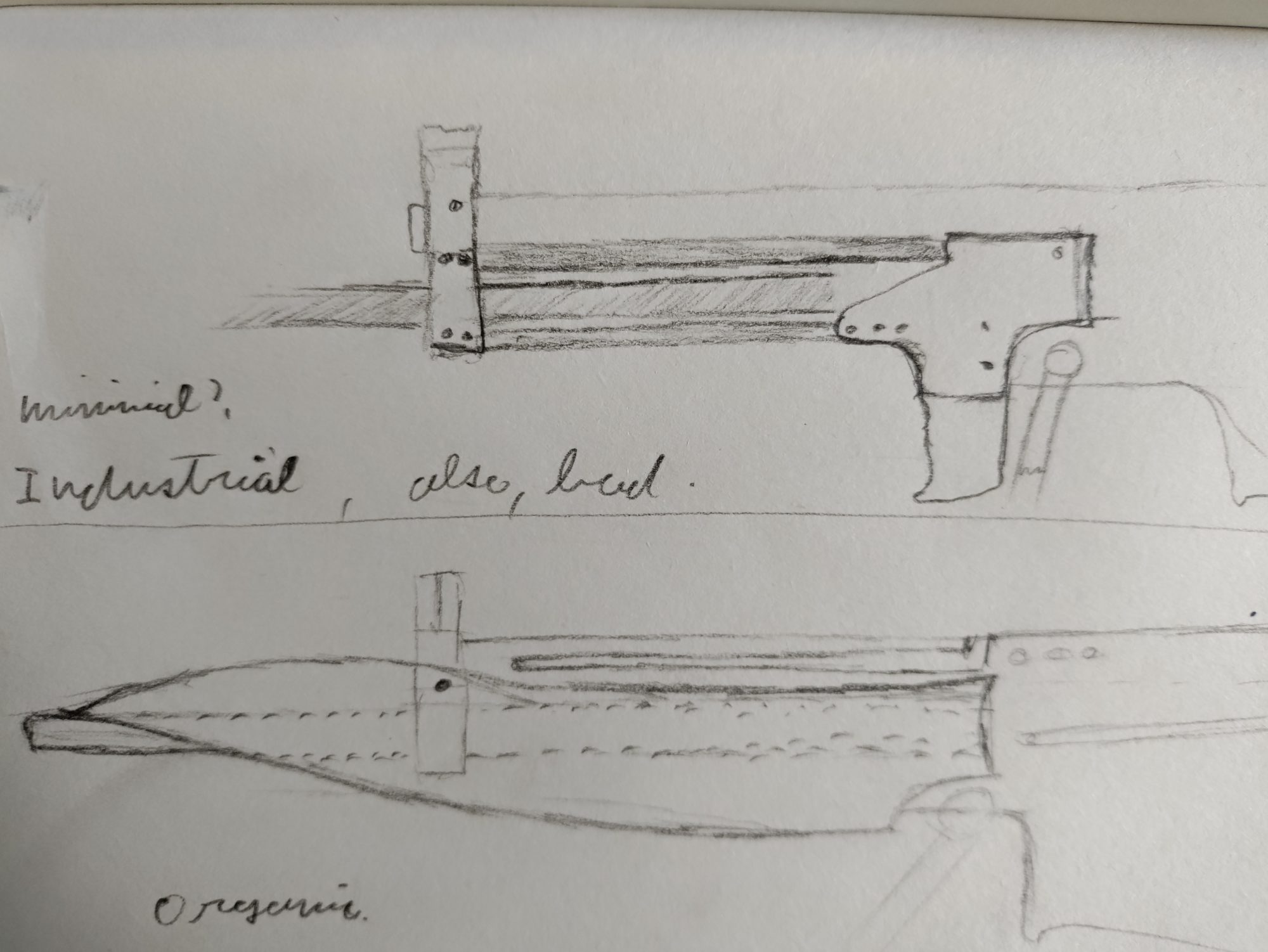

For the aesthetics I considered a few options, first thinking of matching the original cold-war aesthetic of phosphate coated steel, stained wood, and Bakelite plastic by hand carving a wooden foregrip and milling mounting blocks for the front and ends. After running through the exercises sketching different aesthetics, a more organic shaped foregrip fitting over a similar mounting block. Examples of these can be seen below:

.

Cold-War Aesthetic Sketch

.

Concept Mounting Block Sketch

.

Alternative Aesthetic Concept Sketches

.

.

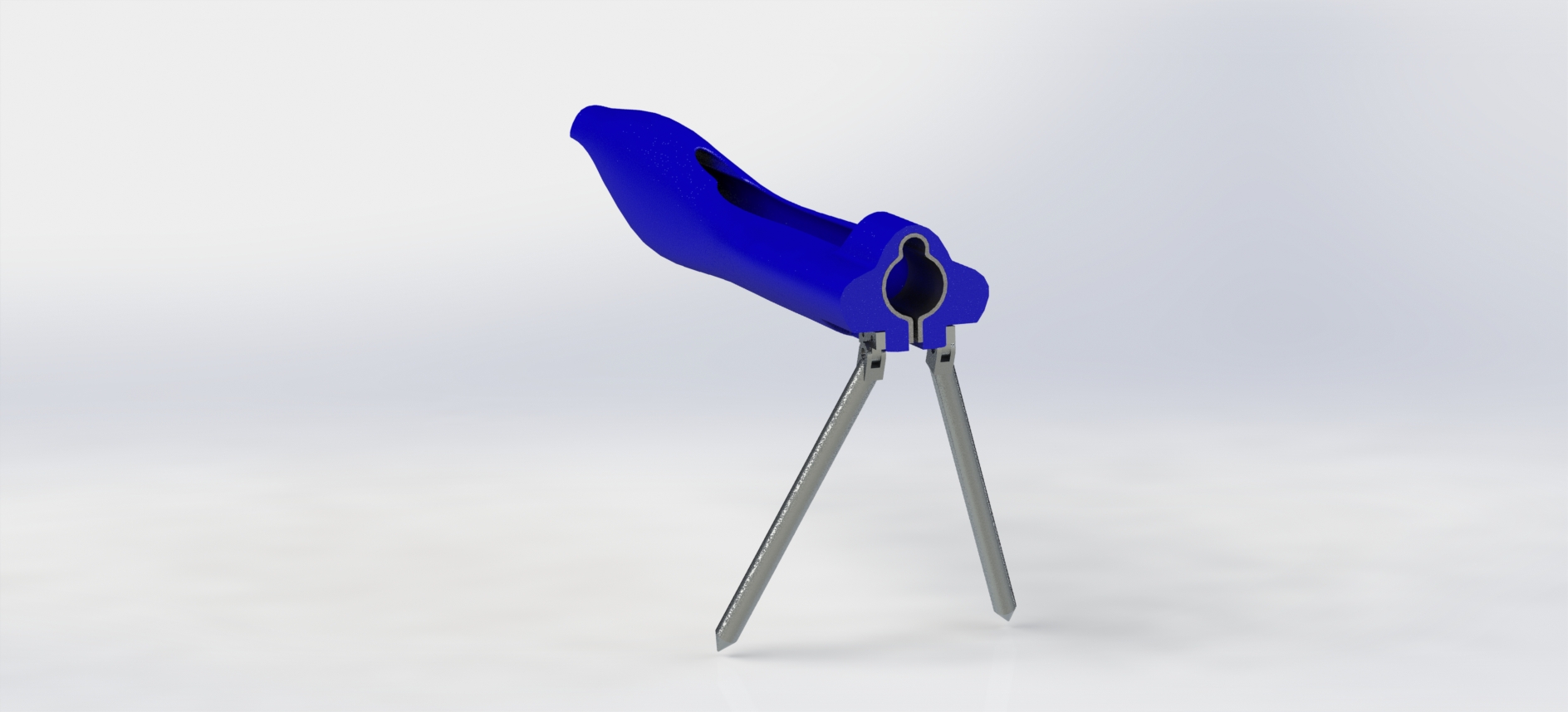

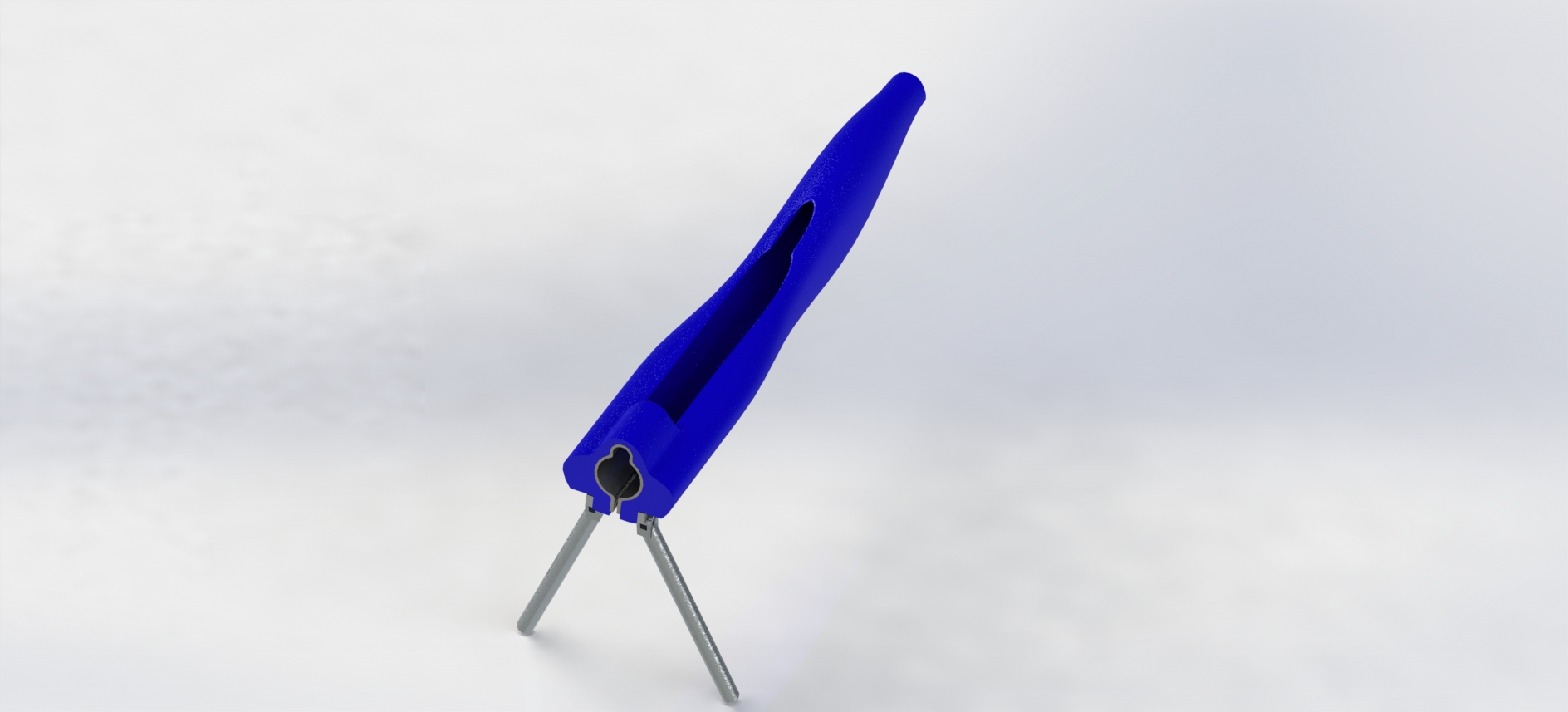

The organic design above I adapted into a rough 3D model, a few views of which can be seen below. The profile is not exactly the same as my initial concept sketches, but I believe it provides a geometry that can be gripped once mounted to a rifle and still generally fits the smooth and organic, if still a bit unnatural, profile I was looking for. Originally I had intended to include a mounting solution for a front sight, and this I may still include in a future model as it does not appear in this one. The dynamic element is the collapsible bipod seen mounted to the rear of the foregrip, that would be bolted on through both the plastic grip itself as well as a metal mounting block that in this example is designed as if made from bent sheet metal.

.

.

As one could imagine looking at the renders above, I have not had the chance to prepare to fabricate this product yet, but have considered the manufacturing. Currently the plan would be to either mill or bend the mounting block and an adapter from this block to either an off-the-shelf bipod or a custom one I mill and turn down myself. The bipod in the models above is not a manufacturable or well designed part, but simply a placeholder to demonstrate the functionality. Also bolted to this mounting block would be the body of the foregrip, made of 3D printed plastic, likely PLA+ or an engineering grade SLA resin for a later model. Given the limitations of print bed size, I would consider printing in sections and combining them with adhesive, reinforced with thin steel rods that could be heat fit if a thermoplastic was used. Depending on how horrifying the rest of this semester is, I may be able to get around to printing a model of this to verify fit, and especially ergonomics.

References:

SolidWorks

1 Comment. Leave new

Hey Ivan!

Your 3D model is beautiful. Really well done.I really like how thought out this idea is, even if you won’t be able to bring it fully to completion.