I’ve been working on cars with my dad since highschool. Most of the work has been light modification type stuff and maintenance stuff. I wanted to start doing some fully custom work and thought I could start some of that with this project. Ever since I’ve been into cars I’ve been enamored by cantilever suspension setups. I never thought I had the ability to make anything like that until recently. After some research, I realized that you can make a cantilever suspension setup without much trouble and keep the geometry rather simple.

I wanted my design to showcase the suspension and be the centerpiece of the rear area of the car. I thought a maximalist aesthetic described this well. I also wanted the design to be functional and demonstrate an engineering approach. Many of the designs I’ve seen from hobbyists are over-built and kind of dull (for a cantilever suspension setup at least). I wanted to use the engineering knowledge I’ve gained during school to design a setup that does not look like all other setups and only utilizes the necessary amount of material to barely work safely.

Ref [1]

The specifications I chose were…

- The suspension is going to be used for street driving and racing, so it must be functional first and foremost.

- I want the suspension to be modular. I’d like to make it so the suspension can be placed and removed from a car then placed into a different car without a ton of work. I’d also like the few parts that make up the suspension to be modular as well. This requires bolted connections rather than welds mostly.

- I’d like the suspension to also be adjustable. I don’t know a whole lot about suspension dynamics right now so I want to design some adjustability into the setup. Along with the modular ability giving some adjustability, the parts themselves will have some adjustability where possible. The bell cranks that connect the coilovers and pushrods will have multiple connection spots that provide different lever arms which change the effective spring rates, for example.

- I want the design to be unique and one-of-a-kind. A lot of the setups I’ve seen so far on YouTube are very similar and a bit over-built I’d say. I’d like to try to design something that looks different from other hobbyist designs and use my engineering knowledge to make something that just barely works.

- I’d like the suspension to have a “sleeper” aesthetic while still being the centerpiece of the interior/trunk. By sleeper I mean I want the suspension to look dirty and industrial from manufacturing and rather simple design-wise but if you take a longer look at it you can see thought and engineering went into making it. I also want the suspension to be the centerpiece of the interior/trunk which I think will be very easy to do given the general geometry of my design to begin with.

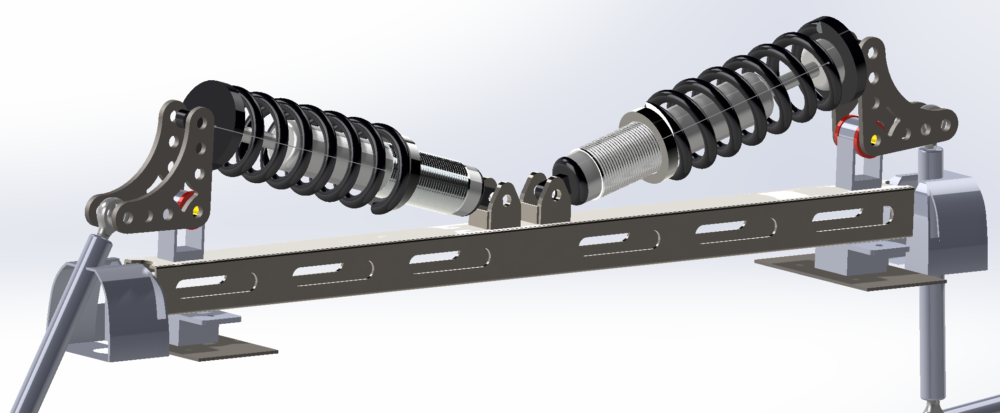

With these functional and aesthetic goals in mind, I began designing the suspension for one of my dads SN-95 mustangs. After taking most of the needed measurements, I developed the design seen below in CAD.

I believe this design has a maximalist aesthetic because it takes up a majority of the trunk area of the car and you can’t miss it. This type of design isn’t necessary for a cantilever suspension setup but does a great job at drawing any observer’s attention. I added my own personal and engineering look to it by designing bell cranks that look different from any other setups I’ve seen and iterating on their design to make them barely work within a factor of safety that should be safe enough.

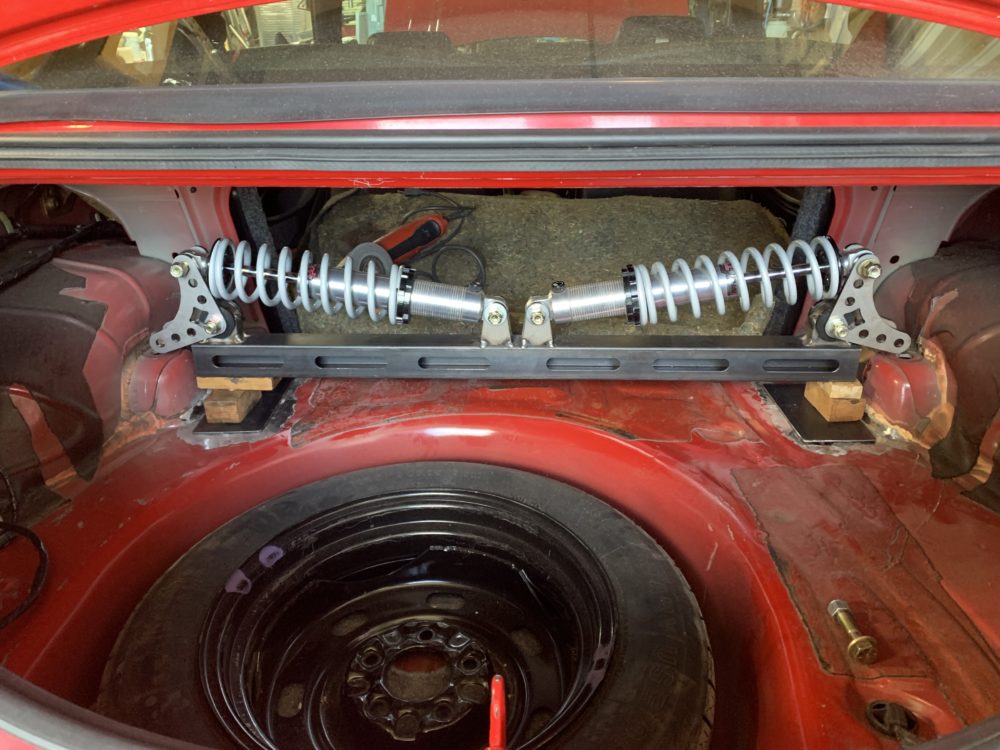

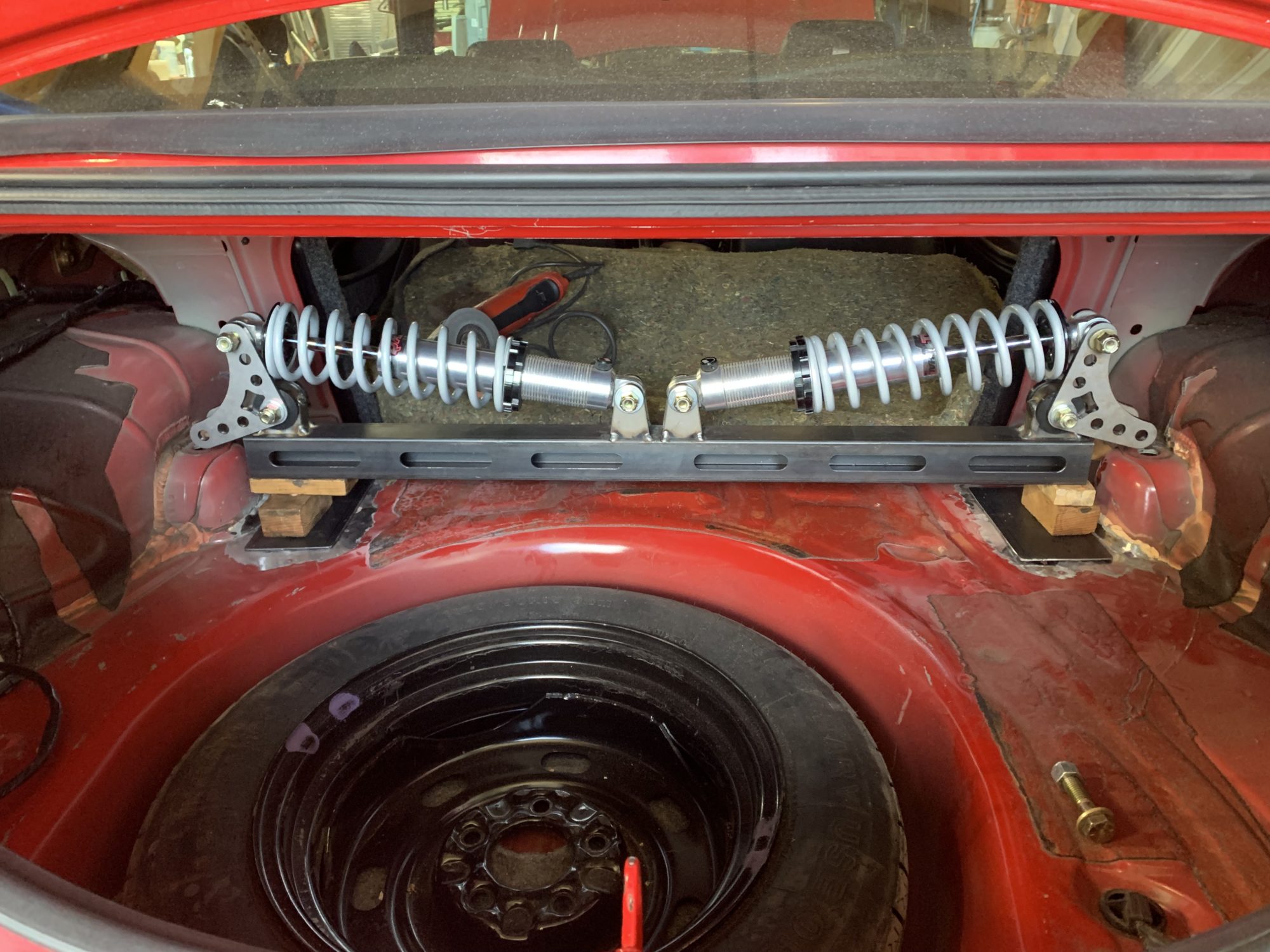

After spending the past 3 weekends trying to fabricate the suspension, I’ve been able to get a lot of work done. A picture of where I currently am in the fabrication process is seen below. As you can see, it is not complete yet, but it is close.

I’ve made some concessions in the design to try and finish it in time for this class’s project. At this point I have not been able to finish the project and set the car onto suspension. I think I could continue with this design and possibly finish it before the semester ends but I’m not sure I want to. Once the semester ends and once some other things happen, I’ll redesign/remake parts of the suspension to better fit my new needs and vision. Because of this, I don’t want to fully make all the parts and fully weld everything together just to trash it a couple weeks/months later. Having said that, I am extremely happy with what I’ve been able to get done for this project and believe that what I currently have does get the general point across of what my project is and should do.

References

- https://forums.nasioc.com/forums/showthread.php?t=2452016

- https://www.motortrend.com/how-to/131-0809-jeep-wrangler-jk-evo-lever-coilover-suspension-kit/

3 Comments. Leave new

Awesome build project!

I’m working on a similar setup for my Datsun 280zx, would you still happen to have to CAD files for the bellcrank, can you email it to me? I’ll purchase it?

Also where did you purchase the supporting parts in your post?

Thanks Terrance Thompson

Awesome build project!

I’m working on a similar setup for my Datsun 280zx, would you still happen to have to CAD files for the bellcrank, can you email it to me? I’ll purchase it?

Thanks Terrance Thompson

I’m really excited to see your cantilever suspension project taking shape! As a fellow car enthusiast, I can appreciate your desire to create a unique and functional design for your dad’s SN-95 Mustang. I think it’s fantastic that you’re applying the engineering knowledge you’ve gained during school to make a suspension setup that stands out from the typical hobbyist designs.