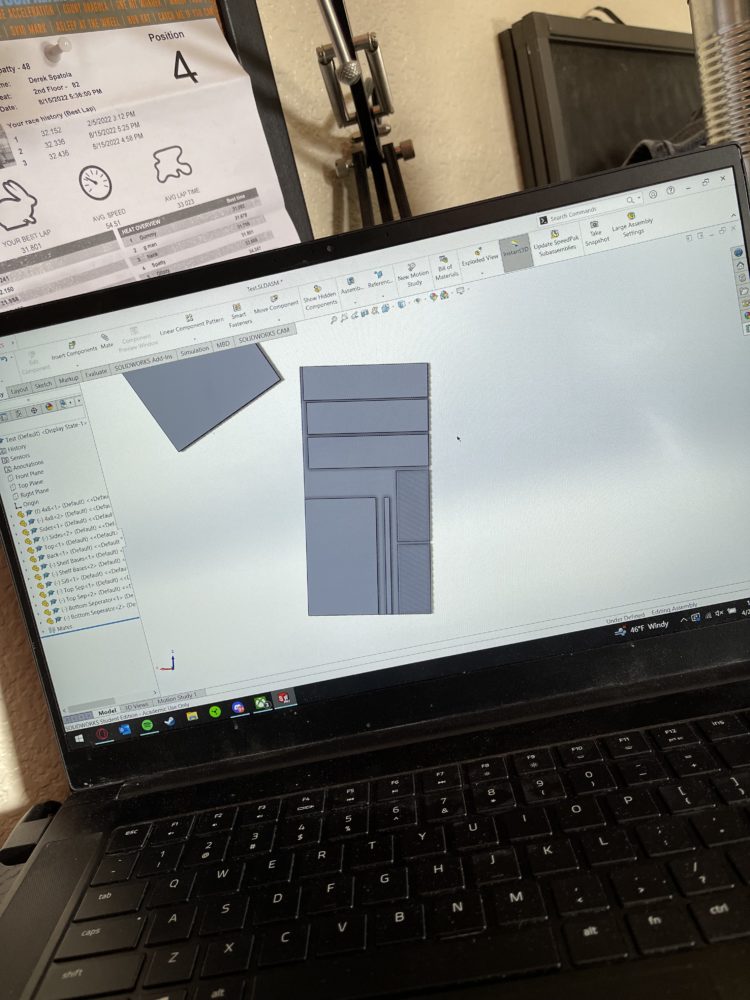

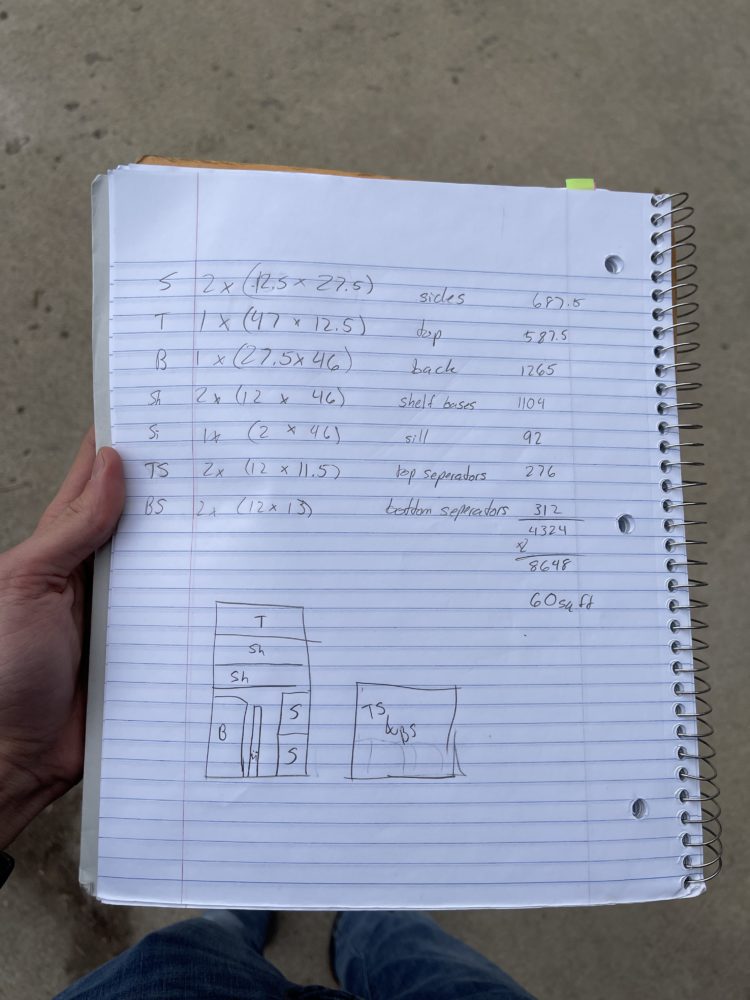

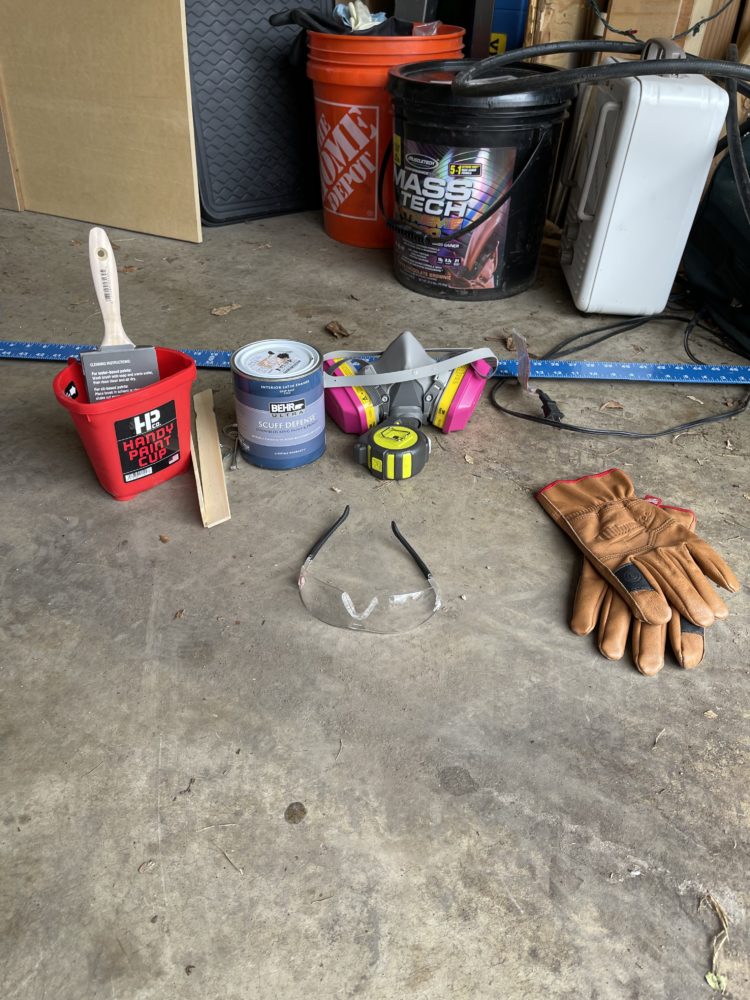

Since my last post, I have gotten less done than I would have liked, but I believe I am still on track to finish the project on time. I made a SolidWorks assembly composed of all the different-sized boards I thought I would need. The assembly was mostly for making sure that all the board sizes that I thought I would use would actually complete the shelf in the correct way. I then created another part as a 4’x8′ sheet of MDF (that I could purchase) and proceeded to overlay the pieces I used in the other assembly. This allowed me to calculate easily the number of boards I would need, which ended up being 1 full sheet of 4’x8′ and a quarter sheet of 2’x4′. I purchased these materials and some other things I would need to finish the project.

Since my last post, I have gotten less done than I would have liked, but I believe I am still on track to finish the project on time. I made a SolidWorks assembly composed of all the different-sized boards I thought I would need. The assembly was mostly for making sure that all the board sizes that I thought I would use would actually complete the shelf in the correct way. I then created another part as a 4’x8′ sheet of MDF (that I could purchase) and proceeded to overlay the pieces I used in the other assembly. This allowed me to calculate easily the number of boards I would need, which ended up being 1 full sheet of 4’x8′ and a quarter sheet of 2’x4′. I purchased these materials and some other things I would need to finish the project.

I began cutting pieces out of the large boards and time-lapsed the process, there are over 5000 photos to filter through so I will complete that for the final report, but all went according to plan and I managed to mock everything up and get a good idea of what the finished shelf will be like.

My next plans are to use a router to make the inlays for the LEDs and drill all the pilot holes for the screws. I have purchased a counter-sink drill bit so that I may use filler to mask where the screws are and paint the whole surface smooth, therefore aiding in the minimalist aesthetic I am aiming for.

I have added the mock assembly timelapse below.

2 Comments. Leave new

I think this looks really great. I always love building things and manual labor in general. It is satisfying work, and you did a stellar job. You may have already mentioned it, but does your shelf have a dynamic component? Either way, I think this is a fantastic design and project overall.

Hi Derek! Great work so far. Also kudos for the time lapse! I am curious what makes this minimalist in comparison to your everyday shelf? Excited to see the end result!