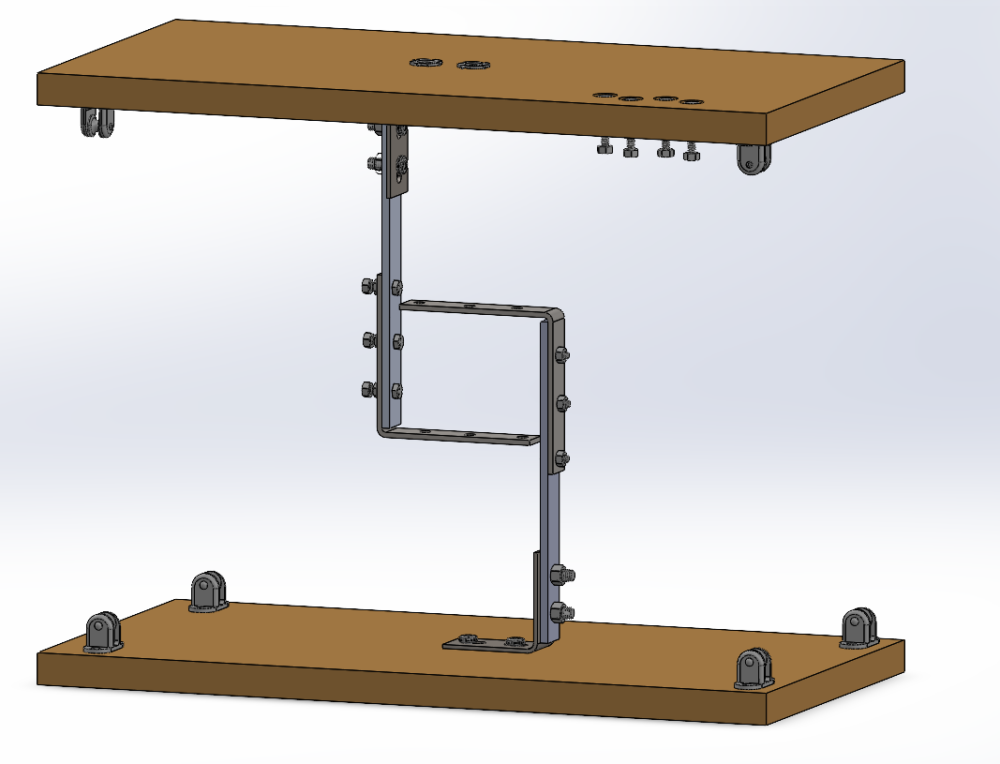

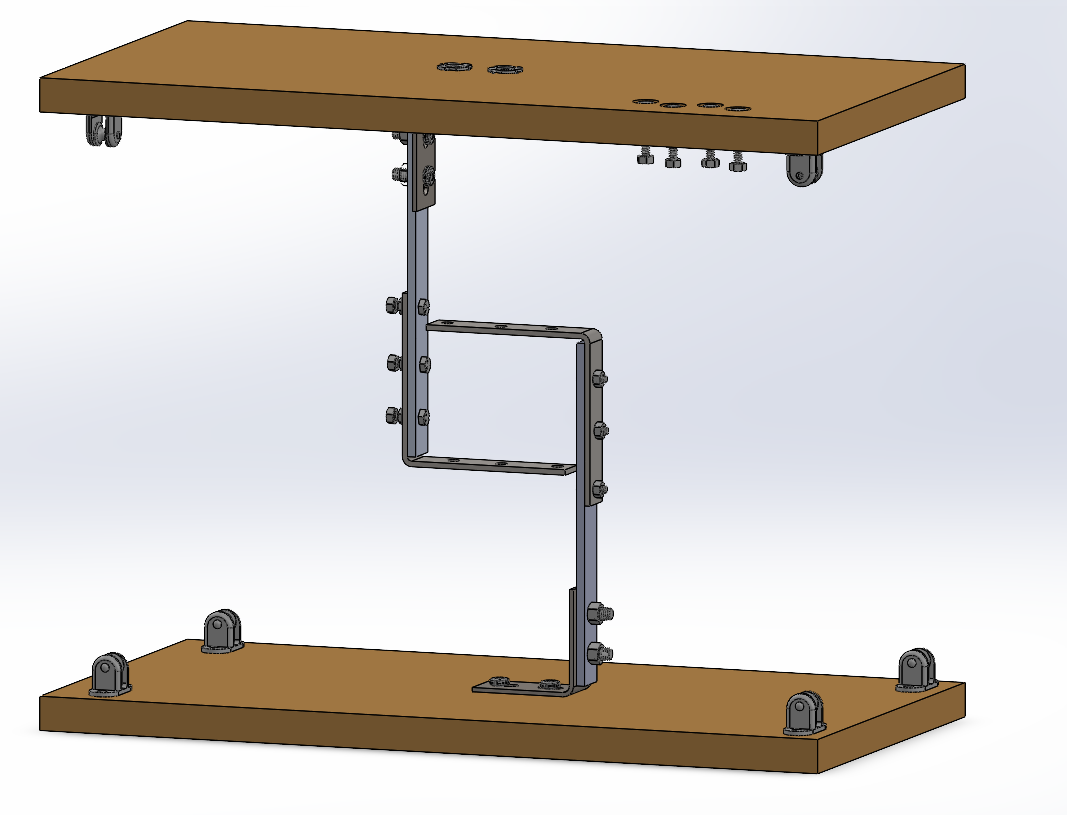

To date, I have purchased the majority of my materials needed with the exception of a cable which I plan on sourcing from a bike shop to use a strong breaking cable which will allow me to bend the wire well around the pulleys and wire securing areas. I have also purchased and cut my wood surfaces to size, gotten 7 pulleys, and some “L” brackets due to a design change. My current CAD assembly can be seen below.

As you can see above, I had to change the design from the initial where the two center bars were one bar that bent at both ends. However, after some testing I realized the material I bought (Aluminum 6063) is unable to bend to 90 degrees at a quarter inch thickness. So, I replaced those with two L brackets that I will fasten to the aluminum bar which will be about 10 inches long.

I currently have the wood purchased and cut to size as you can see below.

The last thing I need to purchase to begin building the table itself is the wire. I also may play around with some wire clamps like the two photos below, but they will be something added in if possible. These would help with precision when determining correct lengths, but aren’t crucial to the design themselves.

2 Comments. Leave new

It’s excellent to see that you’re making work on your project and have already acquired the majority of the necessary components. Your attention to detail is remarkable, and it’s great that you’re making changes as needed to ensure that the final result matches your specifications. I’m excited to see the finished table.

Hi Ben, it seems like your project is coming along. I am very excited to see the final product. How often do you think you will adjust the table?