I’ve finished most of the CAD for the project, and am now working in Mastercam to make the code for the CNC machine to run the operations on the stock metal I bought. I will be using the machine shop in the ITLL to make the parts because it is less busy and they have programmable machines instead of manual ones. The only issue with the manual machines is I wouldn’t be able to get the circles and fillet on the outside contour which is a key part of the aesthetic.

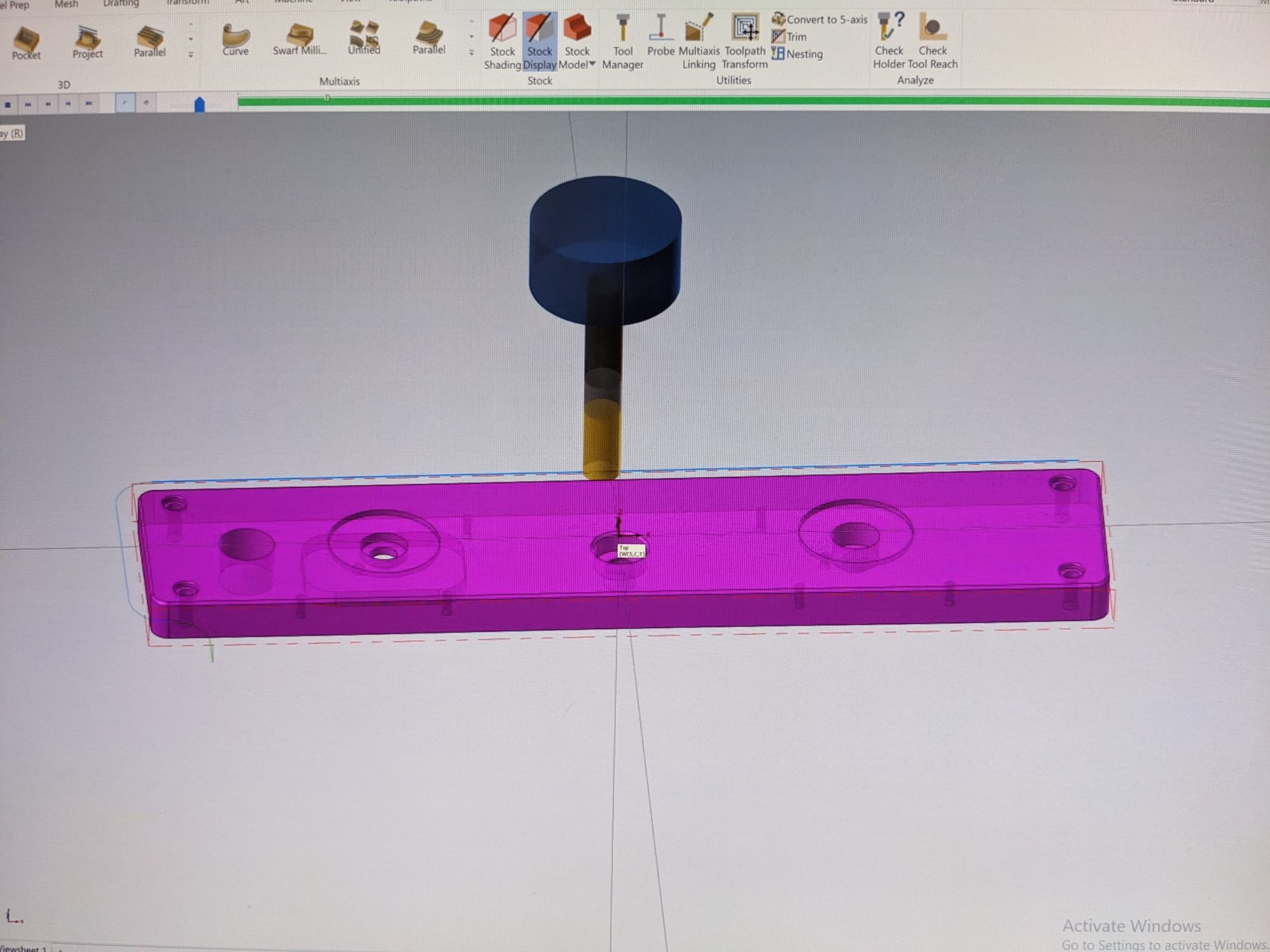

Here is a very low resolution picture I took of the Mastercam software. This is showing the tool path and the part. For each operation there is a main cut to remove material, followed by a finishing cut that removes .01″ from the surface to bring it to the final dimension and gives a better surface finish to the part. This will leave a clean machined finish on the part that I want. I still have yet to test the cote de Genève finish on the aluminum, but I will work with the machinist in the ITLL to use some scrap aluminum to dial in that finish.

1 Comment. Leave new

Wonderful design procedure, how do you think you will get the outside rounded parts?