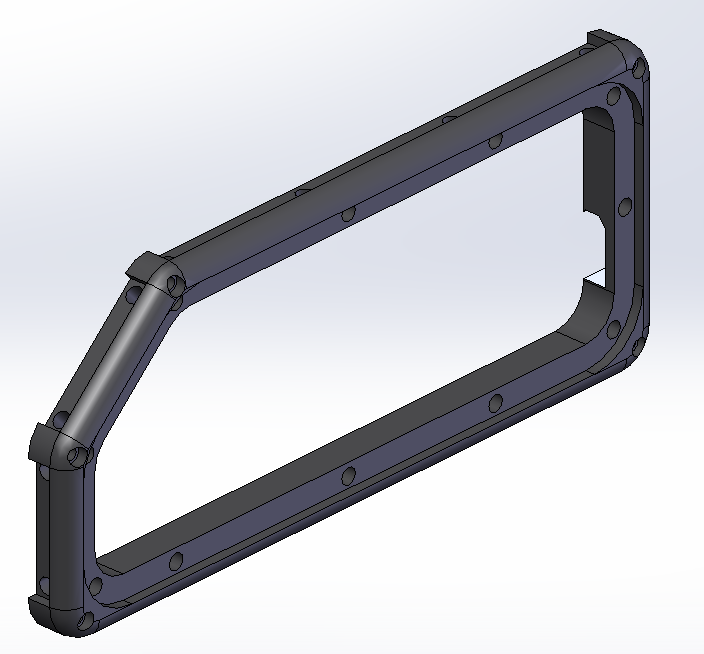

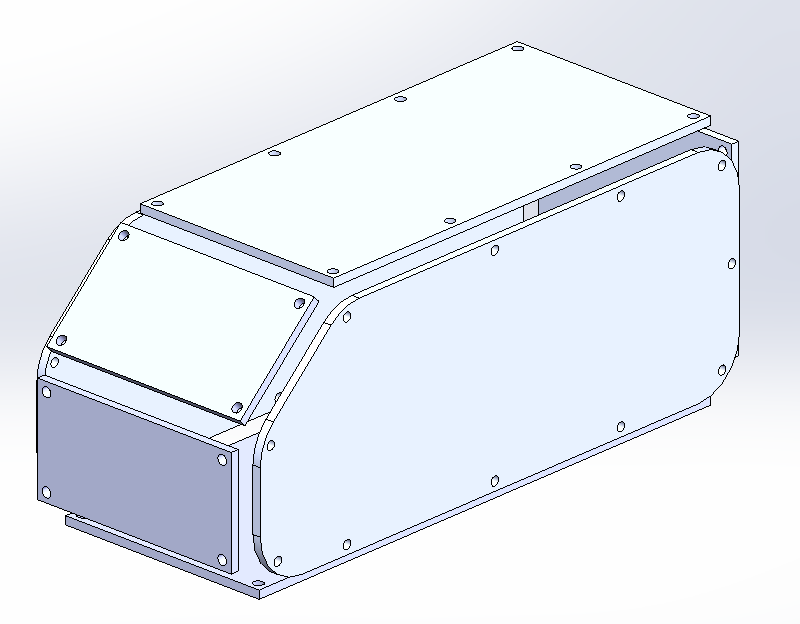

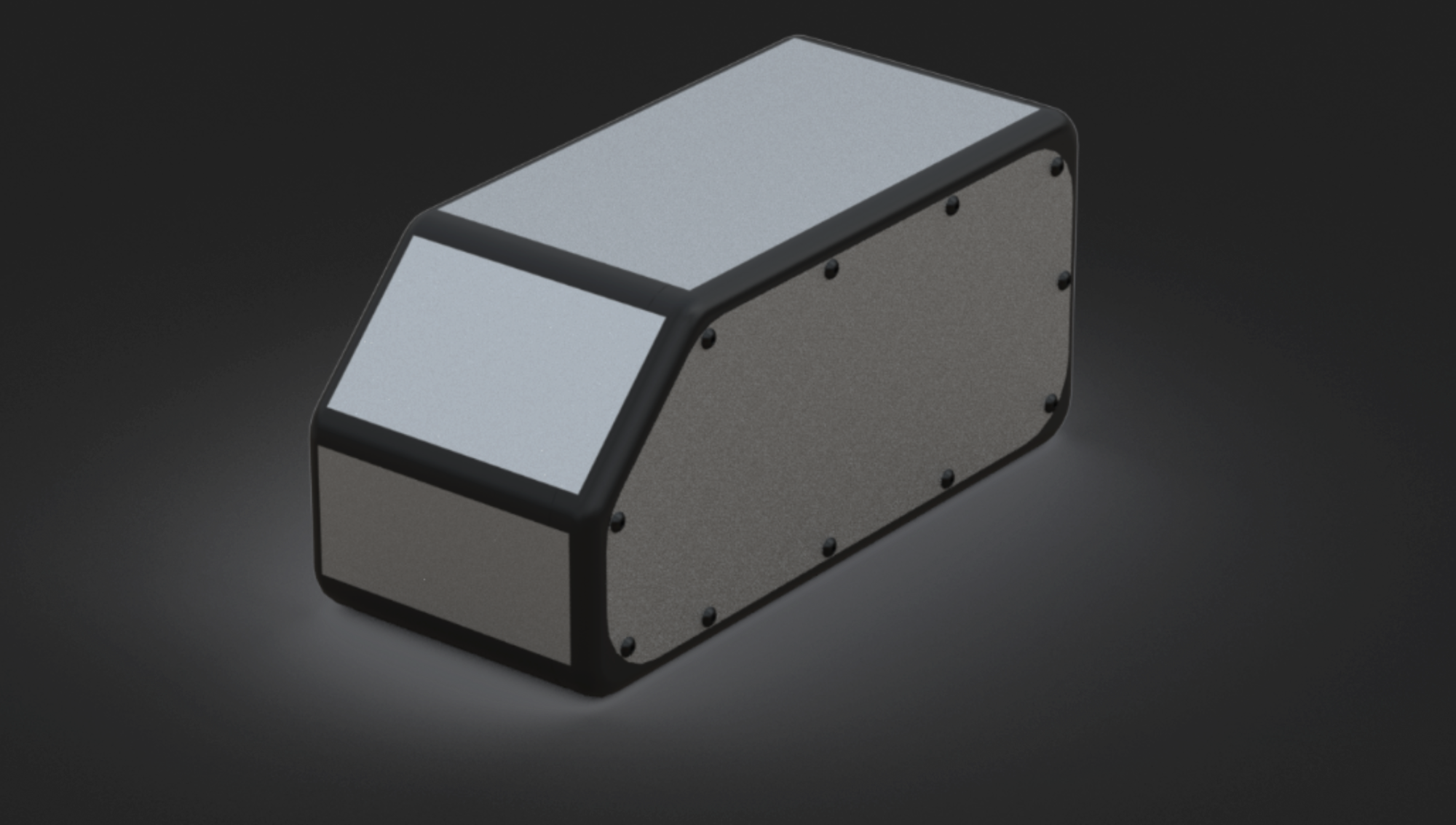

I have finished designing the enclosure for the battery and have started on the electrical side of things. As far as fabrication goes, I have had some major setbacks. I have attempted to 3D print the frame of the enclosure 3 times with each time resulting in a failed print. This is not great as I don’t even expect the first iteration of this to be fully functional and so the final product is going to take much longer than expected.

The aluminum panels I plan to inset into the 3D printed frame have also not arrived yet and at this point I am concerned I am not even going to be allowed to waterjet these parts. If I am unable to waterjet these pars, then I will have to turn to the old template and coping saw method. This would increase build time tremendously.

As far as electronics go, I am in a more comfortable spot. I have ordered a Battery Management System (BMS) and have all the correct batteries to hook up to it once it arrives.

2 Comments. Leave new

I like the look of the design, is there a specific aesthetic that you’re associating with the design?

This is a really cool project to follow and I love the work that you have put into it. Making batteries is something that I’ve attempted in the past but never gotten to work. Can’t wait to see the final product!