I have made a lot of progress since my Design Preview. At the time of the preview, I had cut all the individual pieces for the mold and worked on making them fit nicely together. I have finished modifying individual pieces and now have the top and bottom sections of the mold glued up. The next step for the mold is to use an orbital sander to smooth out any edges present from assembling individual pieces. The bottom half of the mold looks very smooth and continuous. I don’t expect to need to touch up the bottom much. However, I had some trouble gluing my top half together and there are some significant high and low spots. I will sand down any high spots and use a fiberglass filler to fill in any cracks or low points. After the fiberglass filler has dried, I will once again sand the top half to a smooth and continuous state.

Additionally, I created the press using some spare scrap wood I had in my garage and some threaded rods purchased from McGuckin’s. This task was very simple and was a nice break from the methodical iterative process of creating the mold. The press is held together by 8 spars and 1/2″ threaded rods.

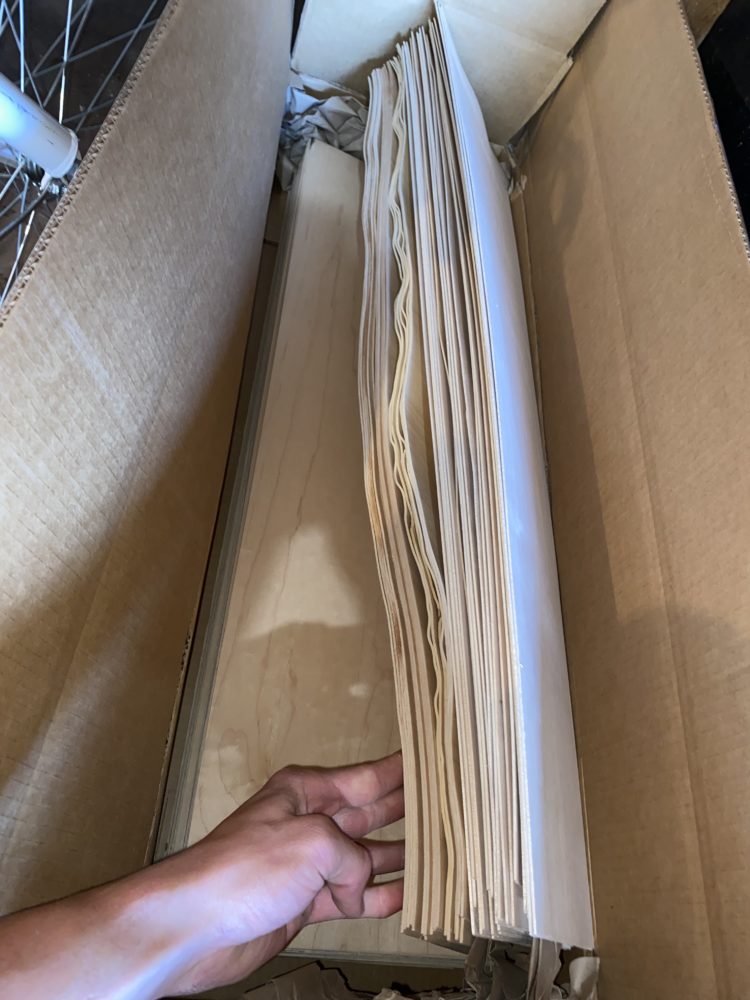

Last but not least, my maple veneer arrived! I had trouble finding an affordable option for veneer in the size that I needed and ended up purchasing a bulk quantity to get the most bang for my buck. I currently have enough veneer for 10 decks and plan on slowly using it all as I will inevitably break each board after enough use. I also purchased two long sheets of cork to place between the mold halves and the deck veneer. This cork will help to evenly displace the force applied by the press. Finally, I found a website that specializes in skate deck construction and ordered a few sheets of dyed top-sheet maple veneer. While I do not have enough dyed veneer for every board. I think it will be a nice special touch for the deck I create during this project.

3 Comments. Leave new

The mold looks super solid! The fact that you aren’t just making the skateboard but the infrastructure and press to form it is super cool. That def takes a lot of skill and investment to create!

Have you considered making your own skateboard brand and potentially manufacturing on a larger scale to sell them?

HI Lucas, it looks like the project is coming along. I am excited to see the final product. You should take a video of the pressing, I think that would be very cool.

Hi Lucas! This looks like a pretty intense and time-consuming project. At one point I had the dream of creating my own homemade snowboard and building a press but it is incredibly complicated and time-consuming so good for you. I am curious how you made the mold and if you based it on an already existing skateboard deck.