After deciding that I would be creating a light fixture for my final artifact, and finding inspiration to drive the progress of my design. I was finally able to start detailing the necessary pieces and materials needed to construct the fixture.

Since a lot of the inspiration for my project came from the studio Luke Lamp Co in NYC, I decided it could be helpful to reach out to them and see what kinds of processes and materials they use in their designs. What I thought would be a desperate call for help actually turned out to be a flattering compliment. Luke, the principal at Luke Lamp Co reluctantly got back to me, thrilled that I was using their studio as inspiration for my project. Because of this, Luke was happy to help and even gave me an abundance of resources and websites where I could find all the needed materials to make a light (including all the parts and pieces he used when first starting to make these light fixtures). While he did not break down what exact parts and attachments I would need, he ultimately opened up new resources for me to access, which was more than I could’ve asked for.

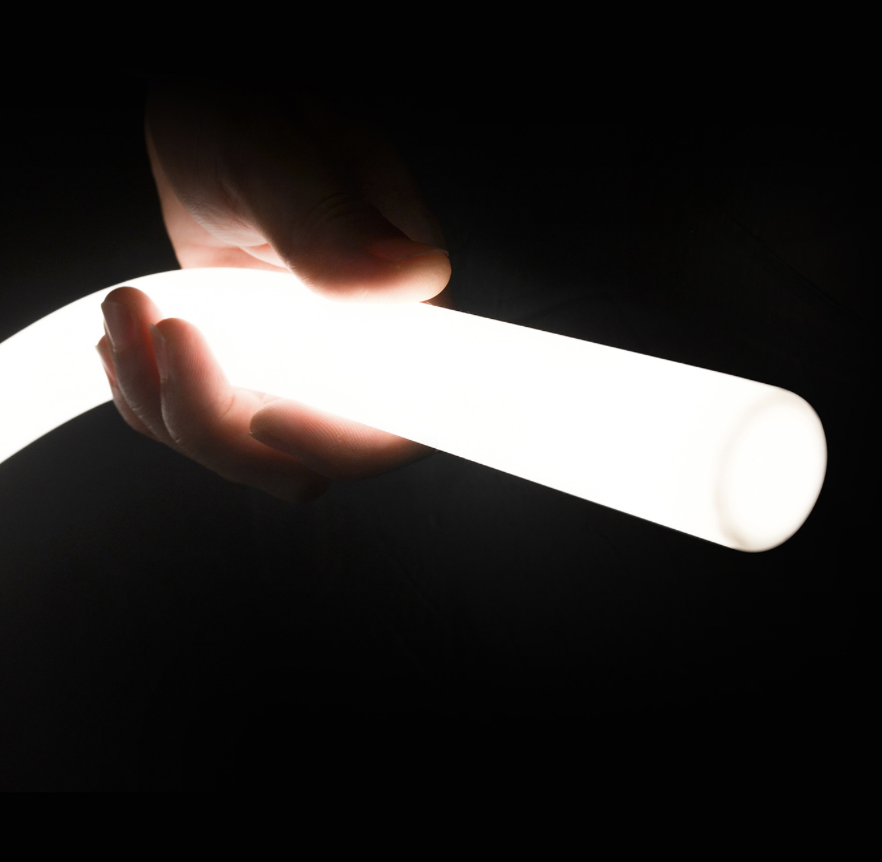

Now with a greater understanding of the materials and parts I would need, I began my search online to start pulling together each component. The most significant part of this light I am designing is the actual rope-like luminaire section that will be illuminated. Since this is the most important and the part I want to be the most accurate, starting the design there would be very useful.

I started by buying two 6ft lengths of LED strip lights, which would be inserted into a silicone diffuser that I found on the internet. The specific silicone diffuser that I chose ends up being 15/16 of an inch so I know that with a white polyester sleeving that I’ll add, I will be right around an inch in total width. I plan on one end of this flexible part being connected to metal piping that will function at the stand or structure of the floor lamp. Metal end-caps will attach each of the metal pipes to the base along with capping off the free end of the rope light. The base will be made of metal as well and will have a 1″ diameter for the pipe to pass into.

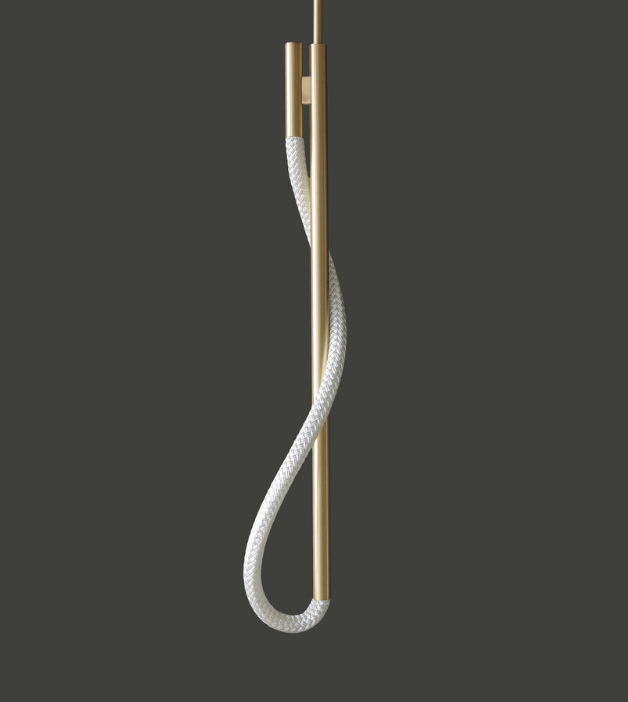

Hopefully, the craftsmanship will come together with this project, that seems to be my biggest concern at this point because everything should at least nominally come together perfectly. Ideally, mine will look like the fixture seen in the feature image above but upside down due to it being a floor lamp. As well as having a free-ended rope instead of it being connected back to the main structure.

Links

- https://grandbrass.com/1-8ips-center-hole-10in-canopy-flat-base-without-wire-way-black-finish/

- https://www.homedepot.com/p/STZ-1-in-x-5-ft-Black-Steel-Sch-40-Cut-Pipe-PDB-P1X60/316939787#overlay

- https://www.mcmaster.com/products/wrap-around-sleeving/wrap-around-sleeving-6/

- https://www.superlightingled.com/%CE%A624mm-silicone-bendable-led-channel-tube-360-emitting-for-8mm-strip-p-5265.html?gclid=Cj0KCQjwuLShBhC_ARIsAFod4fKNGjOuf9xeQrgR8YwZCv2t1P69Px0oVfDu12pYfcA48V7ruKhPg-EaAkXFEALw_wcB

- https://www.superbrightleds.com/led-strips-and-bars/flexible-led-strip-lights/custom-length-single-color-led-strip-light-eco-series-tape-light-24v-ip20-250-lmft-stn-x-b6a-08c1m-24v

- https://www.lukelampco.com/viewall/3-5ftsurreypendant

2 Comments. Leave new

A fine project, and good thinking asking the manufacturer of a similar product about their processes and materials. Do you plan to run it with a simple on-off, or are you considering more complex control systems?

Love the idea of a light source for the project. I am also using LED strip lights in my project, have you considered how you will integrate the power to make it look clean and well crafted?