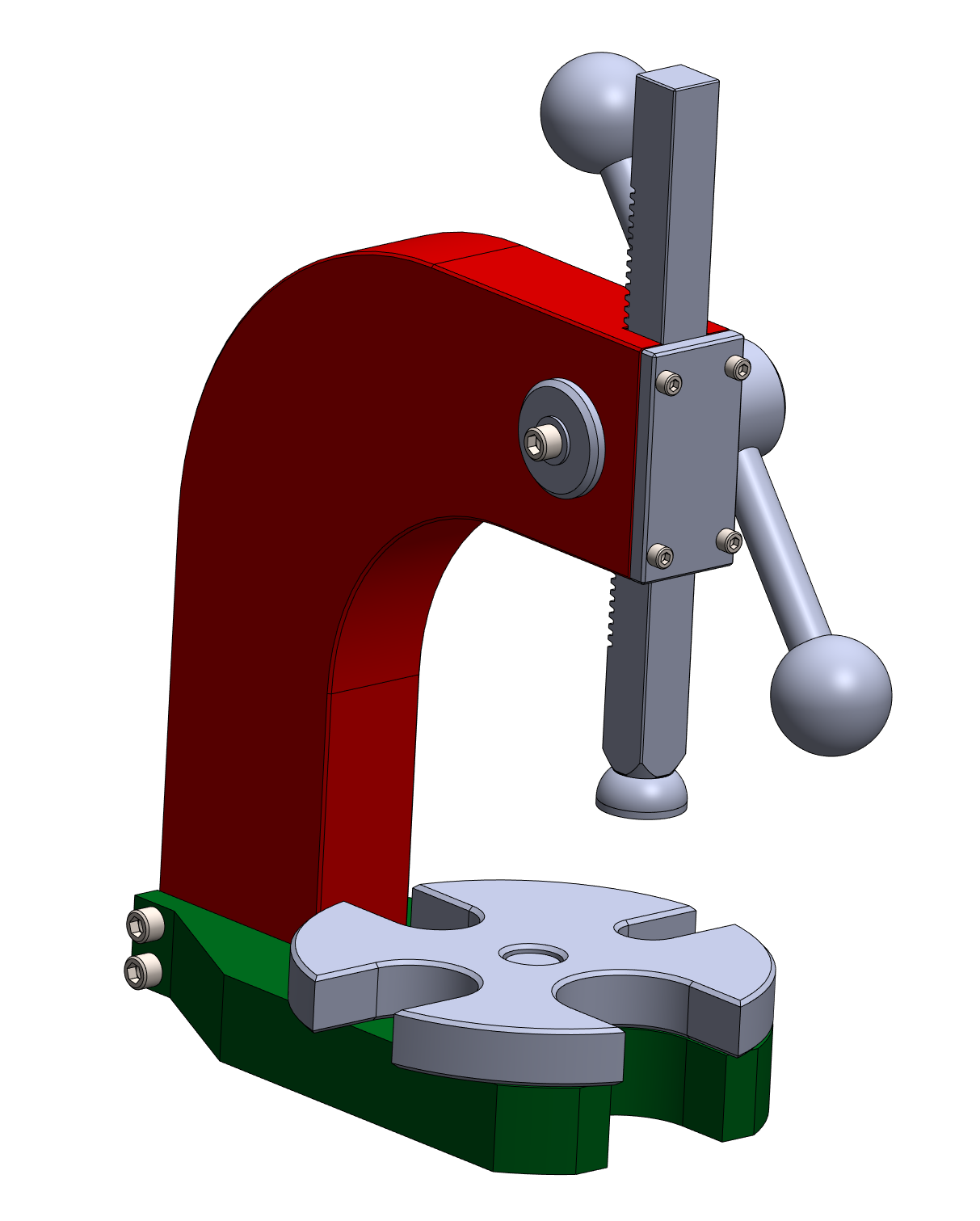

As stated in other posts my main project consists in designing and building a manual press with organic shapes. By now I have designed the CAD model without the generative part done. That is due to the fact that my laptop is not powerful enough for handling such a topology optimization, so I will use the University ones that migh be more powerful. At the moment, as I haven’t been able to finish the CAD I haven’t started building or protoryping anything.

One I finish de CAD design I will proceed to 3D print it, it is likely I use PLA because is cheap and abundant but I am not sure yet. After I have printed all the parts maybe I consider post processing them or directly assembling them to finish the build of the project.

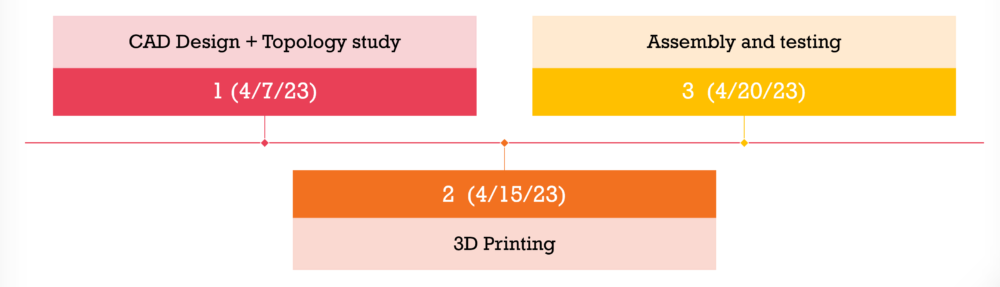

Here is the timeline of the project:

https://www.forbes.com/sites/forbestechcouncil/2020/10/01/10-exciting-ways-3d-printing-will-be-used-in-the-future/?sh=29dd5c75c7f6

2 Comments. Leave new

This is an awesome idea, and I bet the final product is going to look amazing. Using organic and flow-like geometry for something robust like a manual press is a very cool idea, and I can’t wait to see how it turns out! Where will you be putting your project once it’s finished? What materials are you going to press with it?

The study of topology is a very interesting incorporation into this process, and will definitely help your project to differentiate itself. I also love the juxtaposition of machining tools, which do not typically feature organic forms and flowing curves, and natural organic shapes. I would be interested to see how material properties and strength capabilities compare for your materials and design. I am excited to see where you go with this!