.

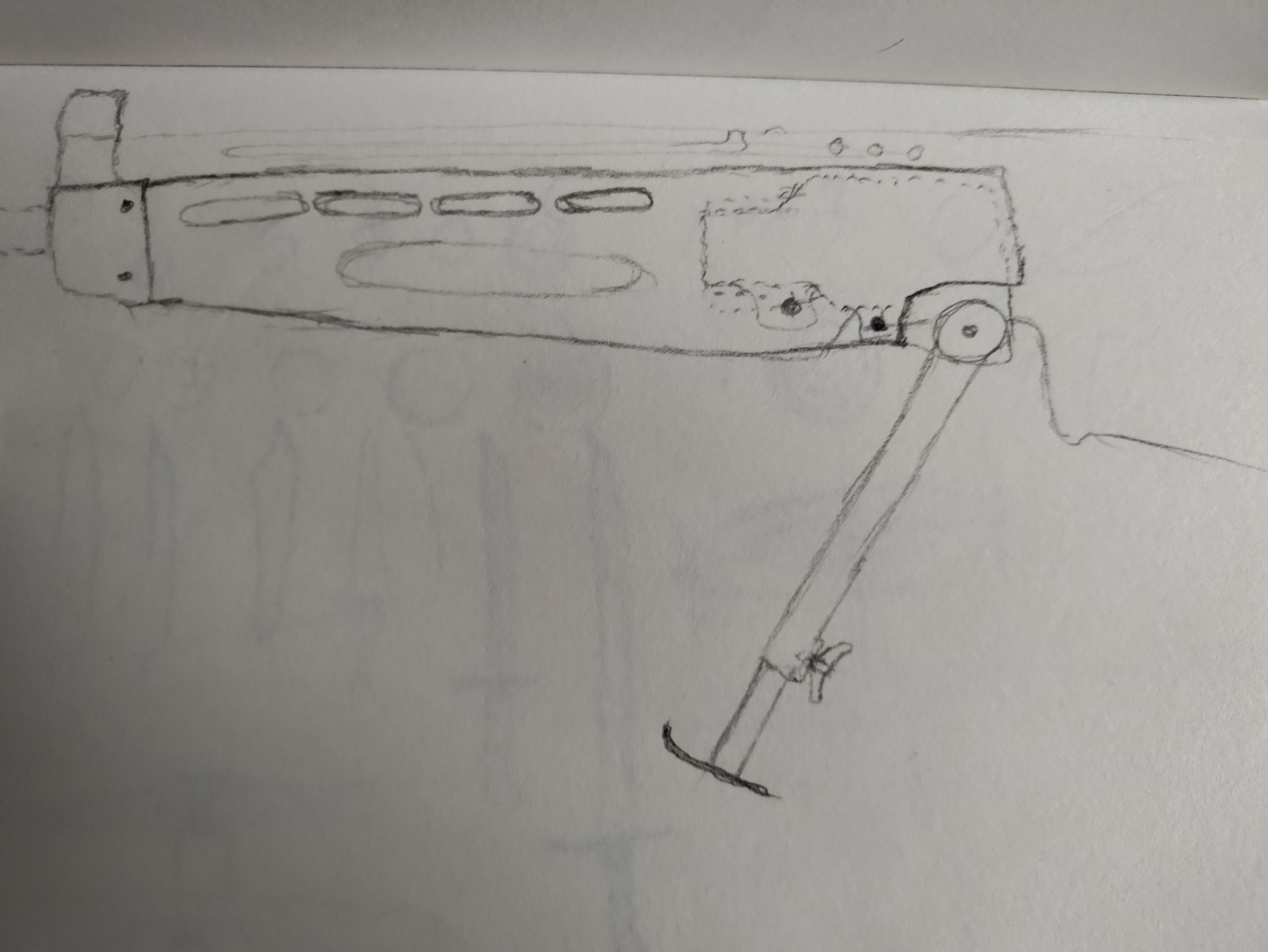

For the main project, I am designing a custom forend for a rifle I have been working on for the past few years that will allow the barrel to free float, which is a desired feature for consistency and accuracy. It will also retain the option of using a front sight, which is usually not compatible with free-floating the barrel on this particular style of rifle. For a dynamic aspect, the mount for this forend will also allow for attachment of a bipod.

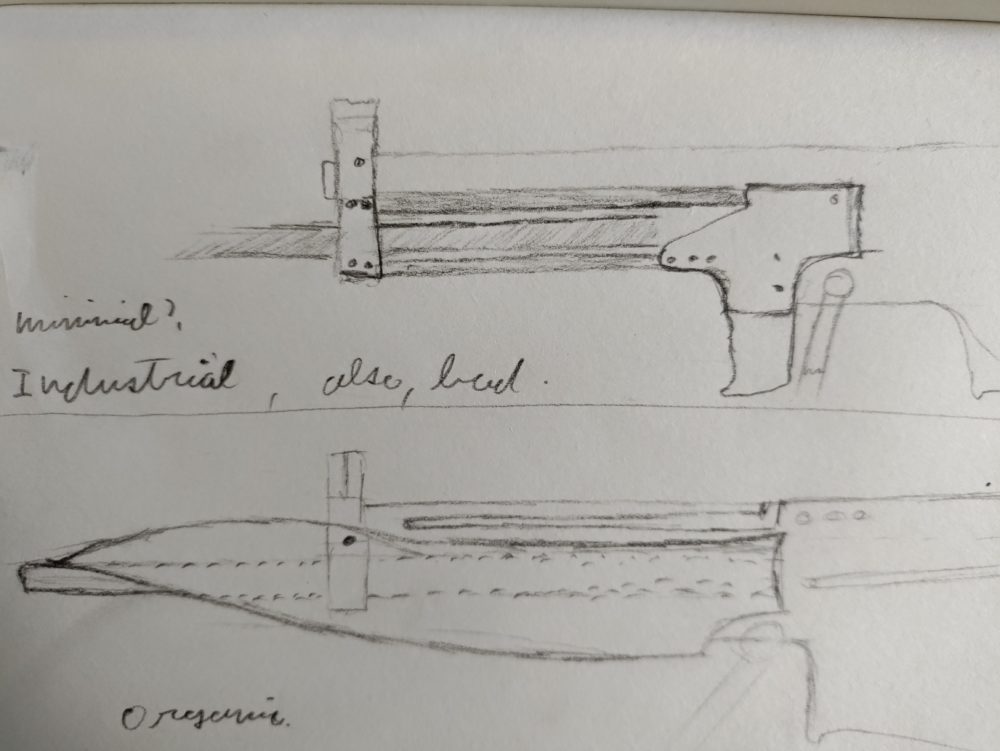

With regard to aesthetics, I have been considering options, and decided to follow a mix of the two aesthetics I sketched out as an exercise, shown below, as opposed to trying to match the existing cold war aesthetic as seen in the featured image above.

.

.

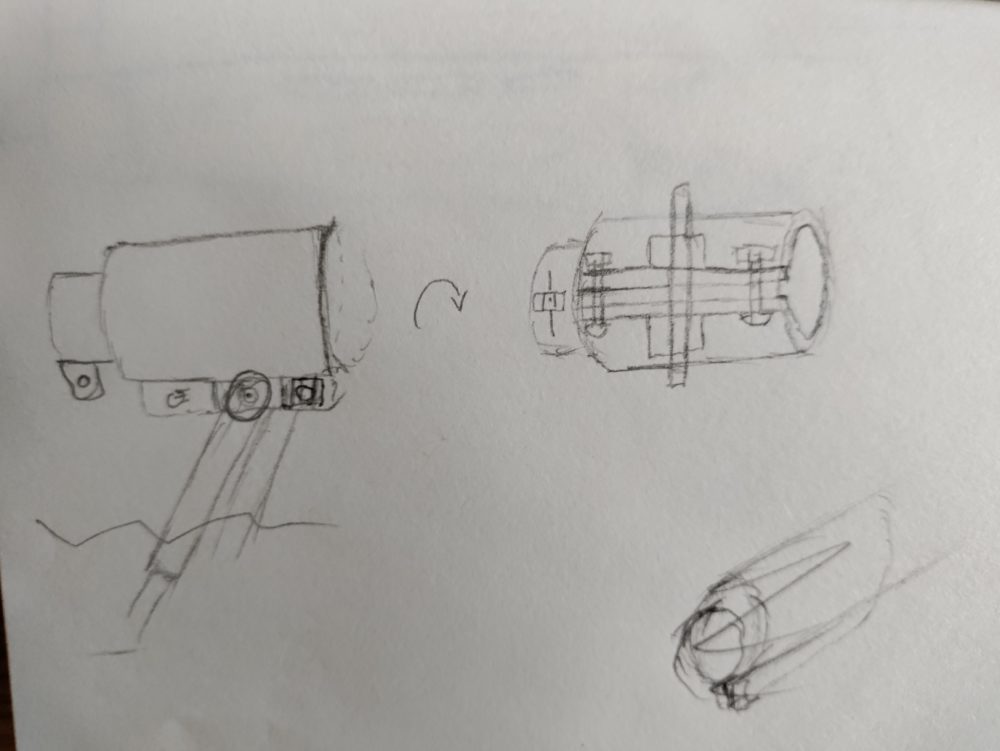

To combine the industrial and organic, this forend will have two parts, primarily a utilitarian rigid metal mount that clamps to the receiver about the trunnion, as seen in the lowest image above, that has mounting points for a potentially more ergonomic organic shell that could be changed at will. This more organic shell is remarkably at odds with the original aesthetic of the rifle, being designed at the beginning of the cold war, and this dichotomy will make for an interesting look to be sure. Whether this will be aesthetically pleasing, however, is another matter entirely.

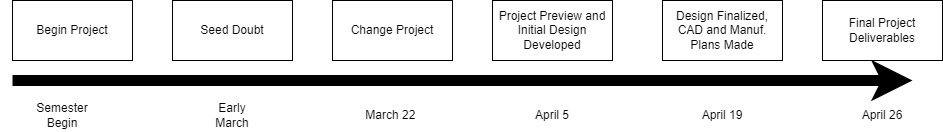

Below is a basic timeline, outlining what has been accomplished, and where I intend to go. From this design preview, I will begin to develop a more detailed design in Solidworks, with manufacturable geometries and respectable renders as equal goals. As for how far I could push this project before the semester ends, it would be just shy of a miracle if I managed to find the time to make so much as a wholly 3d printed mock up, let alone properly milling the mount and bipod. With this in mind, I plan for now to hold good 3d renders that demonstrate the function and aesthetic as the final deliverables. If I manage to find the time, I will try to 3d print a mock up to better demonstrate the wildly different aesthetics by mounting it on my unfinished rifle.

.

.

For manufacture of the first model, I intend to make the mount or clamp as milled from aluminum, with steel bar stock or rods, perhaps threaded, connecting front and rear milled blocks as well as the bipod. The shell will be 3d printed, likely PLA, for ease, affordability, and variety of color and finish. For later models, a stamped sheet metal mount with steel rods welded between would be much lower profile for the same strength, and a cast (or injection molded if production is considered) high-temperature plastic for the shell would far surpass printed PLA.

.

1 Comment. Leave new

Epic project. You caught my interest. Props for doing this, as I shied away from anything 2A related. I wonder how far the 3D printed version could go? FossCad has exploded the last couple years. It makes me thing of the “Modern-Sporting-Rifle 15″‘s handguards, which are lined with aluminum heat shields. Free floating the layered 3D print would be pushing the durability. You could potentially reinforce with metal bars/pins/etc. For the attachment of the bipod, are you going direct to a sling-stud type, or picatinny rail? I’ve printed picatinny rails before, and I think it would be far superior than the stud, unless you used an off the shelf part for that.

If I were to undertake something like this, I’d focus on streamlined and narrow. Quad rails, Magpul, etc. are all bulky. Reject Modernity, embrace tradition. Classic M16, Garand, M14, Mosin-Nagant, mauser, etc. all have relatively streamlined and thin front handguards, although the miss the flexibility of today’s QD world. If you haven’t/aren’t aware, FossCad is a budding community and has great ideas on how to push the 3D printer to the 2A limit. I’m playing with a twenty-two 1911 slide in my free time. It’s a long way off, but some fun CAD work.