As with my previous project, I wanted to create something that fits within the coffee house aesthetic. The earthen tones and subtle flashes of greenery are incredibly soothing, and conducive to productive work. The natural material of furniture often found within a coffee shop also has a certain appeal, and whether it be leather couches, a potted plant, or wooden tables, the subtle hints of nature and dark tones pair very nicely. An example of the coffeehouse aesthetic can be found below:

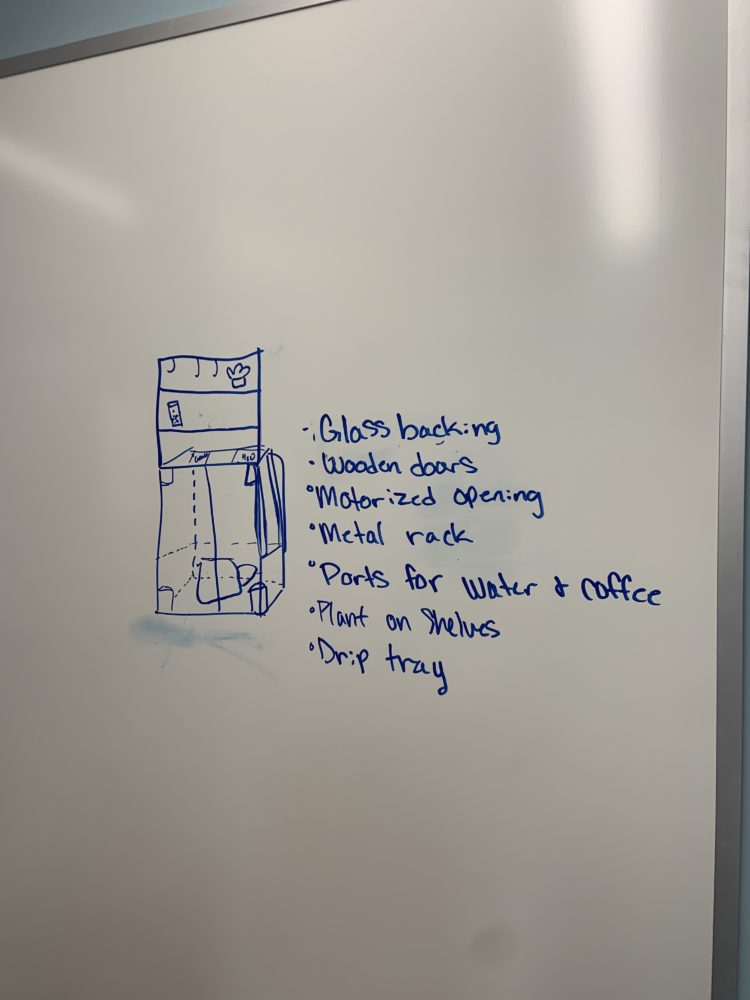

As a lover of the coffeehouse aesthetic, it felt right to create a version of the machine that inspired it all –the coffee maker– within the coffeehouse aesthetic of course. My initial design can be found below, quite an ambitious plan. The crude drawing details a plan to create an automated coffee maker, with a glass backing, metallic rails on the sides, a wooden exterior. The interior would store water, grounds, piping and a heating element, and an Arduino for stepper motors, which would power an automatic double door system. Plans for a compact-disk like ejector which would slide to produce one’s full coffee mug were also thought of too. The sketch is below:

There were several flaws in this preliminary design. First, the coffee maker was incredibly crowded inside, and the Arduino would be incredibly difficult to wire, with the 6 stepper motors needed to open the doors and slide the mug forward being extremely complex systems. Secondly, insulation was an issue. The thinnest insulation that could handle the immense heat of the heating element I could find was originally created for water heaters, and was incredibly thick itself. The internals were already getting cramped, and the mug still wasn’t inside. The solution that I best figured was to remove the “CD ejector” slide, and to simply have platform for the mug. Now, the internals are still cramped, but I believe that I can figure out a way to work around that with a trip to a hardware store to get small piping, and being smart with space.

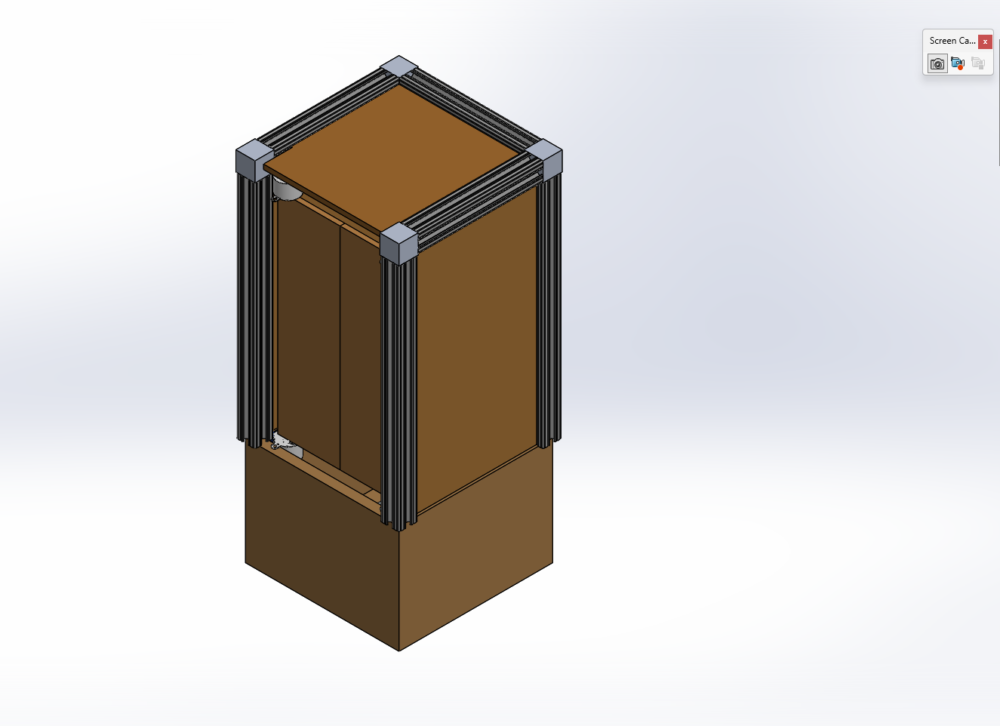

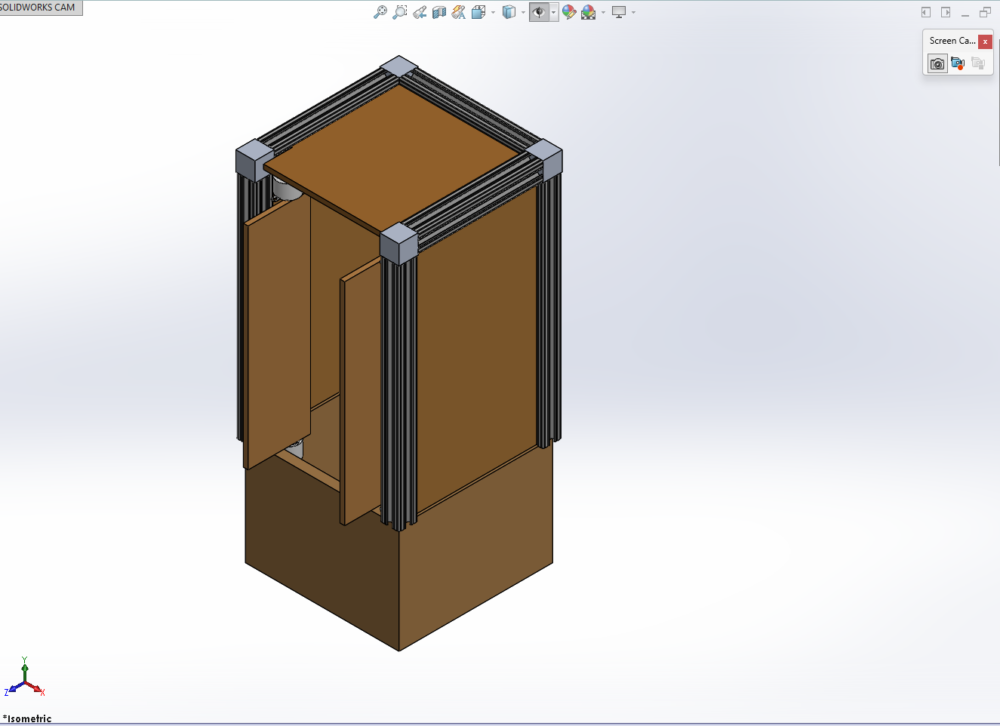

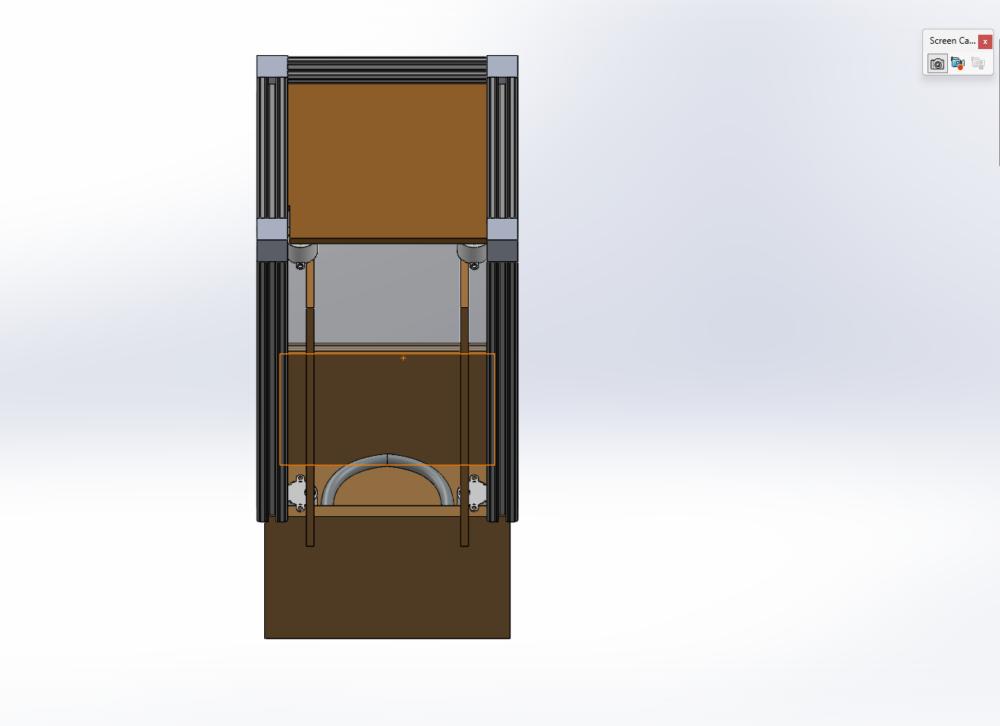

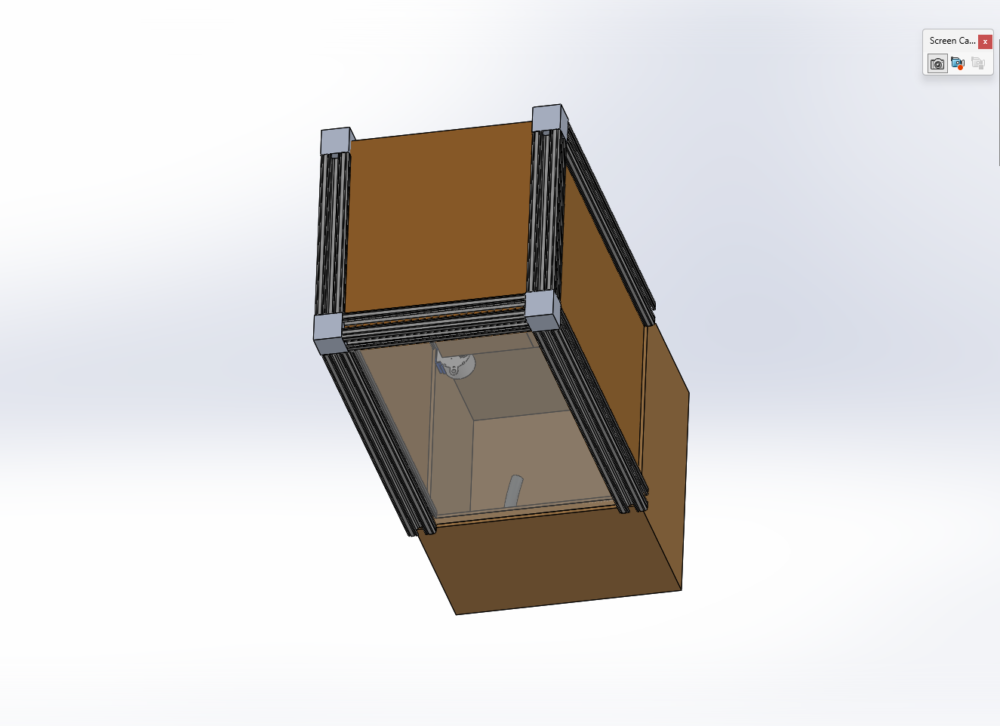

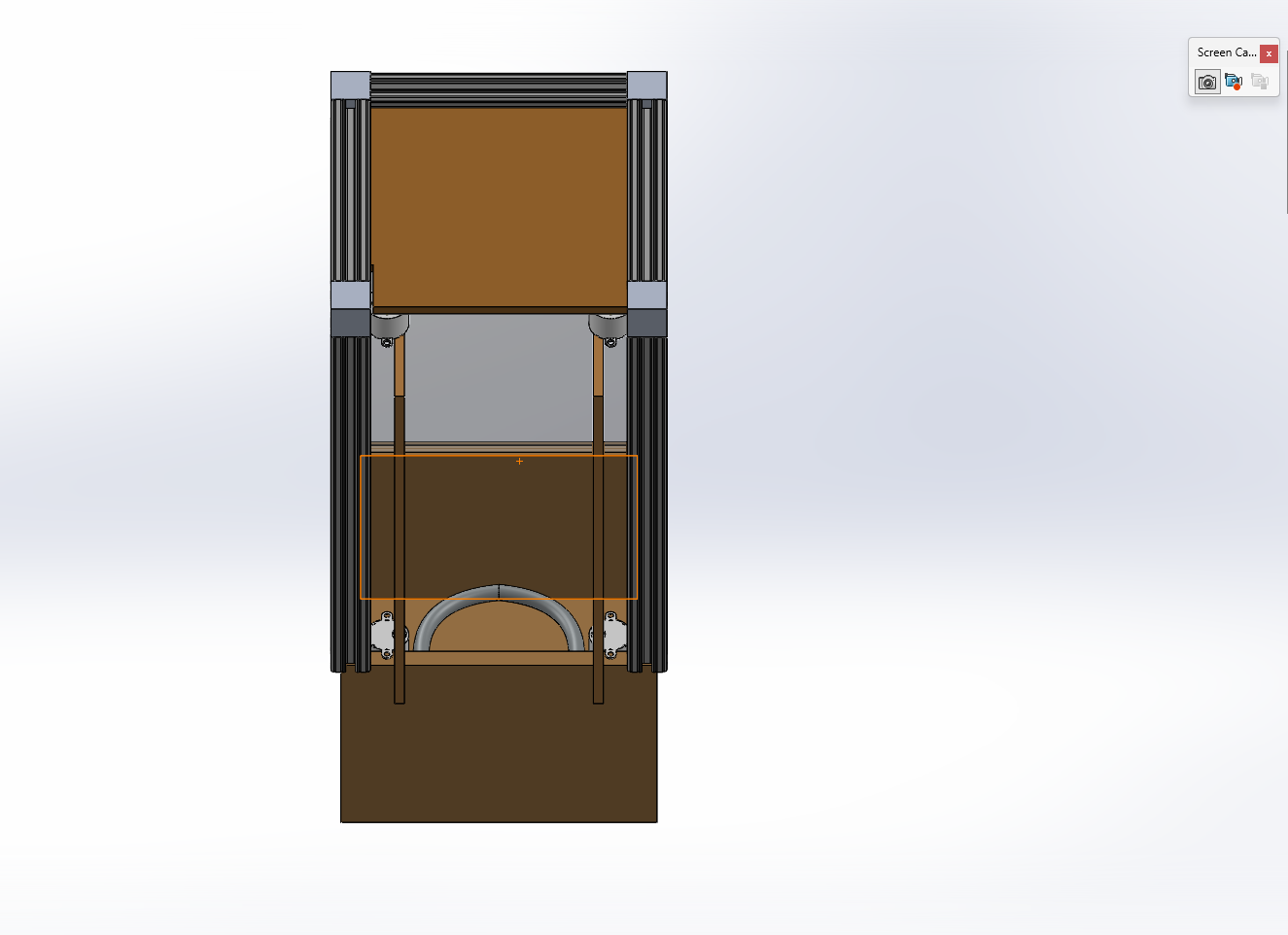

Thus far, I have created a SOLIDWORKS assembly to model the coffee maker, and have figured out the dimensions of the piece. These are below:

Within these drawings, one can see the metallic rails which line the coffee maker, as well as the wooden top, sides, and doors. These metallic rails are often used for the fabrication of optical tables, though their T-slot creates a perfect notch for the wooden siding to simply sit within. The backing, once glass, will now be 1/4 inch thick acrylic, as I can simply laser-cut the material to the right size, and I couldn’t do that with glass. The horseshoe-shaped piece in the middle is the heating element, and the rest of the interior isn’t shown.

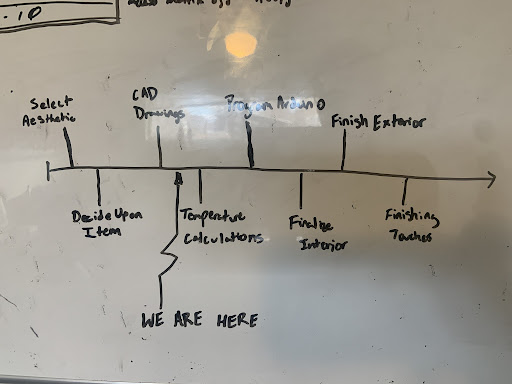

A timeline of the piece appears as follows:

The parts I need to finish the process have either recently arrived or are on their way as of 4/5/2022, and I believe that once everything is here I can make fairly quick progress. I have worked with Arduino stepper motors before, and the thermodynamic calculations I need to complete to ensure the box won’t burn down shouldn’t be too hard. The last step will be the exterior, which is simply tapping holes and connecting all of the pieces in the right way.

With luck and careful focus, I believe I can finish well within the deadline.

A video of my presentation from Monday is below:

2 Comments. Leave new

That is a very ambitious project, and the design looks to fit the aesthetic you are going for very well, with the wood paneling and extruded frame. Have you any plans to add cosmetic decorations to the paneling, or keep it clean as in the reference image for the aesthetic?

I think removing the cd platform was a good call because the project is already pretty tough. Also, by any chance would you have a small bit of extra acrylic I could buy off you? I need to make a small screen cover for my project that’s only a few inches big.