In order to better understand my project I must consider the driving specifications and constraints that will be behind the design. In terms of specifications, I aim to have my piece protect the cards it encloses, fit easily in a backpack, appear like a blooming flower when actuating, be easily operable, and look exciting. In terms of constraints, I must consider my manufacturing tools, time, my CAD skills, the ability of the project to actuate, and through documentation.

My main specification is that the box must be able to protect the cards it encloses, as this is the primary function of a deck box. This includes being thoroughly sealed from the surrounding environment, not being able to open on accident, and not compressing or bending the enclosed cards.

Figure 1: quantity of cards contained in average deck box

My second most critical specification is that it should be easy to fit in a backpack, as the box will not only be used to store the cards, but also transport them. This may prove tricky, as the shape required for the box to feel like a lotus blossom will make it notably larger than the actual volume of the cards it will contain.

Another important specification is that the box opening should feel like a flower blossoming. This is the purpose of making my own custom card box, is to give it a unique and aesthetically pleasing opening experience.

Despite the grandeur of the opening process, an easy opening experience is also among my important specifications. In order to make sure the box can be conveniently accessed by myself or anyone else, the actuation method needs to be simple and intuitive.

Finally, it is important that the design looks and feels exciting. The custom nature and unique opening experience lend themselves well to this specification, but it is still important for me to consider this as the experience of opening and using the deck box can have a positive impact on my excitement to play the deck it contains.

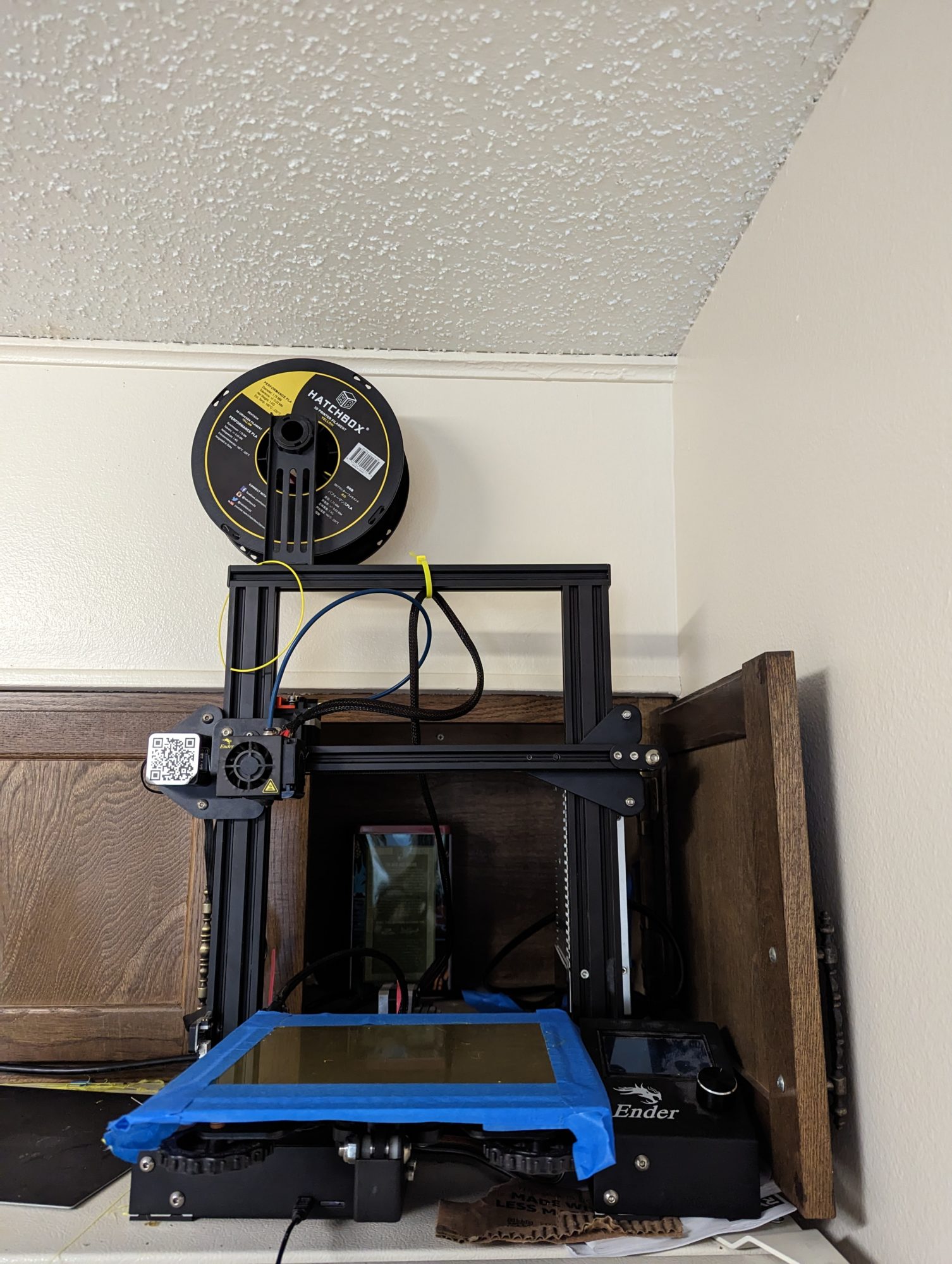

My greatest constraint will be the manufacturing methods used to create the deck box. This is a self imposed constraint to ensure that manufacturing is not impacted by potentially unseen issues. To ensure this I will be manufacturing the final product on my own 3D printers at my house. This limits me in material, form, and the time it takes to manufacture parts, but is not subject to issues such as long wait times and potential overcrowding such as can happen in the machine shops at the end of the semester.

Figure 2: available printers for manufacturing

My second largest constraint is simply time. I foresee the design of the actuating apparatus and the aesthetic form of the product to take a lot of time and as the semester progresses I have increasingly less time to complete this.

Another critical constraint is my CAD skills. Although I am thoroughly versed in Solidworks, a more organic form such as a flower might best be modeled, at least in part, in a mesh modeler such as Maya. I have limited experience with such modeling software, so I will either need to figure out how to express my aesthetic goals parametrically or learn how to integrate mesh modeling into my design process.

A constraint placed on this project by my specifications is that I will need to design each piece for movement and actuation. I anticipate this further adding to the time it takes to design and test my project as well as the materials required to make it.

Finally, one very important constraint is that the project must be well documented. I have often struggled in the past, especially with creative projects to take adequate documentation as I design my projects. Since this is a critical part of the final report I must make sure that opportunities for documentation are built into every part of my design process, not just the mechanical aspects.

1 Comment. Leave new

Alexander,

Your lotus deck design is inspired, though seems incredibly complex. With time as one of your constraints, I think it’s a great sign that you’ve started now. The same goes for documentation, you’ve done a great job thus far. With the organic shape and lack of experience with software programs that create organic meshes, I suggest Rhino. I am not too sure if it is free for us CU students or not, but I do know that it is used often to create organic shapes in professional settings (as an important side note, I’ve never used it myself), just thought I’d suggest it.

I think that you’re doing great, just keep it up.