As my coffee maker is meant to be used regularly long after this project is finalized, I hope that it is a primarily sturdy piece, one that can withstand regular wear and tear that comes with its use. As I am fabricating this piece in the coffeehouse aesthetic, I have several other wants and needs that the piece has to meet aesthetically.

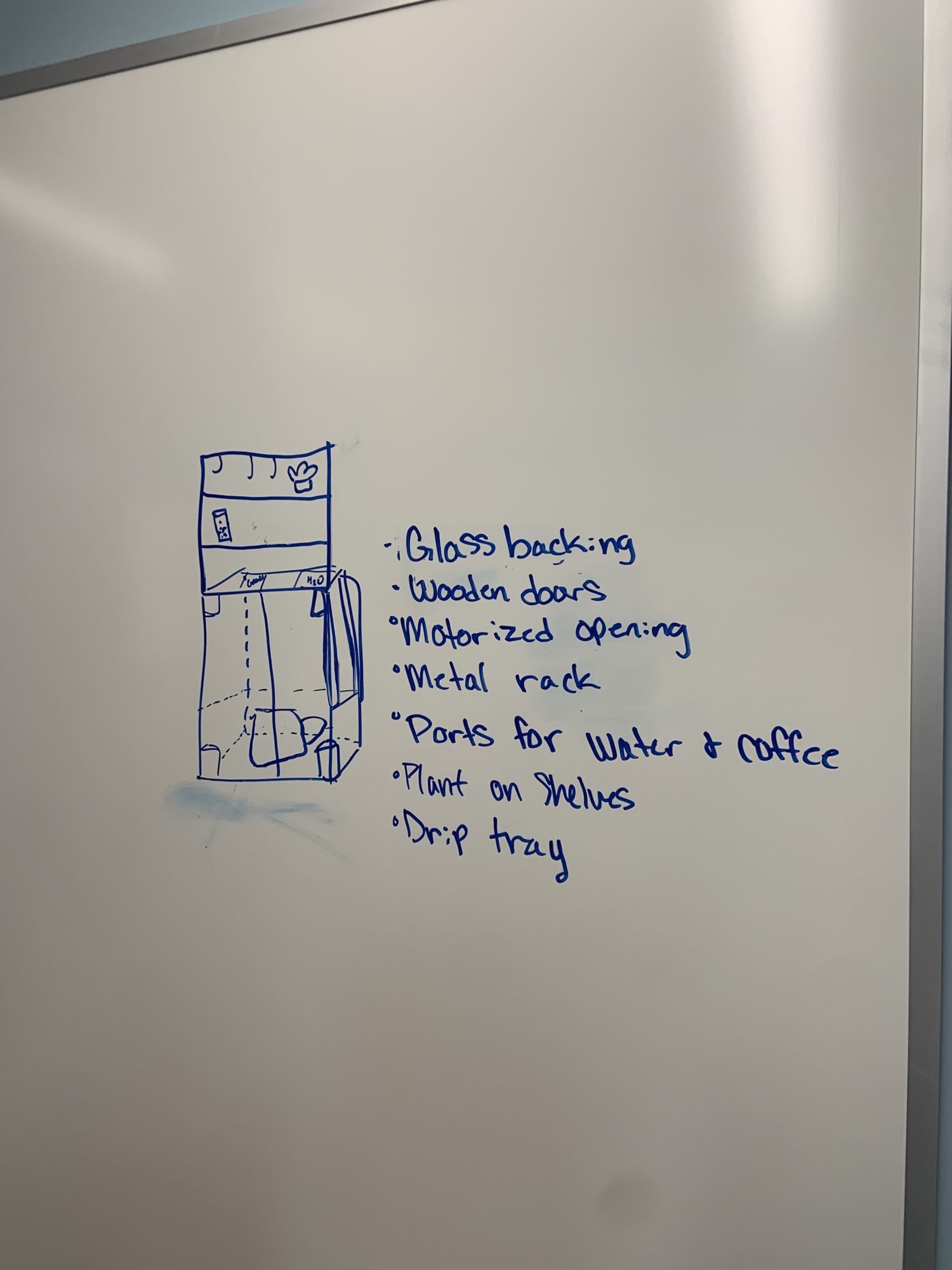

First, it has to be sleek, and compact. This is largely due to function, as I have very little counter space, and I plan on using this well into the future. I want the piece to have a welcoming feel to it though, with natural and earthy tones, yet a hint of sophistication. I plan on incorporating automatic doors that swing out and open to reveal the internals of the piece, and I would much like for these to have motors hidden inside, as to maintain an outward appearance of simplicity. I believe that having a glass backing, with metal beams up the side of the piece will look incredibly nice, as well as give the user a peak inside, to both witness the “behind the scenes” of the machine, but to ensure that no problems have arisen. A well-made that is integrated into the machine above the actual brewer itself would be nice, as it adds to a sense of class, but allows for added storage as well. Finally, the machine should be unassuming, having a feel of both class and comfort. Specifically, I wish to have the outside internals blend seamlessly into the wood of the piece, making it look far less pedestrian than one’s average coffee maker.

When the final design is sleek, comforting, and most importantly, functional, I will know I have succeeded. Currently, I am prioritizing working with the internals and constraints of the piece.

Aside from size and dealing with a compact space, my coffee maker has several big constraints I have to work with and around. One of the larger issues is temperature. The coffee maker uses a heating element from an old Mr. Coffee machine, but this component gets incredibly hot; and heat and a wooden casing don’t often mix well. I went and purchased water heater pipe wrapping insulation for the machine to stop fires from starting, but combatting this is going to an interesting task. Next, I face the issue of internals within the machine itself, as I need to cram an Arduino board, a mug or pot, water storage, grounds storage, and heating elements, motors, and wiring all within an extremely small space. I am still working out the best way to move forward with this, but my most practical solution is to use SolidWorks to gain accurate dimensions of the piece, and play with configurations until I achieve success. My two final constraints are time and money. As an engineering student, I am not rife with either of these luxuries, though with discipline and a clear head I believe I can work around these.

Ultimately, the internals and small size of the piece will be the hardest to work around, though I believe that with luck, I will be able to do so.

1 Comment. Leave new

Hi Riley, I love the practical direction you are taking this project. I actually thought about a similar project for a different class, but ultimately I shied away from it. My main concern was Arduino controlled water pump, I’d love to see how you tackle this issue!