For my final design project I am going to make an aluminum amplifier face plate. I decided on this because my dad is an audiophile and has always enjoyed high end audio equipment. Since the equipment is so expensive, it not only has to sound amazing, but look and feel amazing. This means all of the cases are made out of machined aluminum that is either sandblasted or anodized and a lot of thought went into the design of the face plate which is what people see. The interface has to be flawless from a user interface stand point while also being extremely functional and no nonsense.

I am drawing inspiration from the finishes swiss watches have because they are the epitome of luxury and high craftsmanship and I want to reflect that in my design. My dad’s side of the family is also from Switzerland and it would be cool to pay homage to that. There are many different types of finishes from polished to brushed to sandblasted that swiss mechanical watches have, but at the moment I have chosen to go with a Cote de Genève finish (also known as Geneva stripes). It is a simple yet beautiful finish that changes depending on how the light reflects off of it. In order to get this finish, an end mill or abrasive disc is tilted at a slight angle and only the very edge of the is used to remove material.

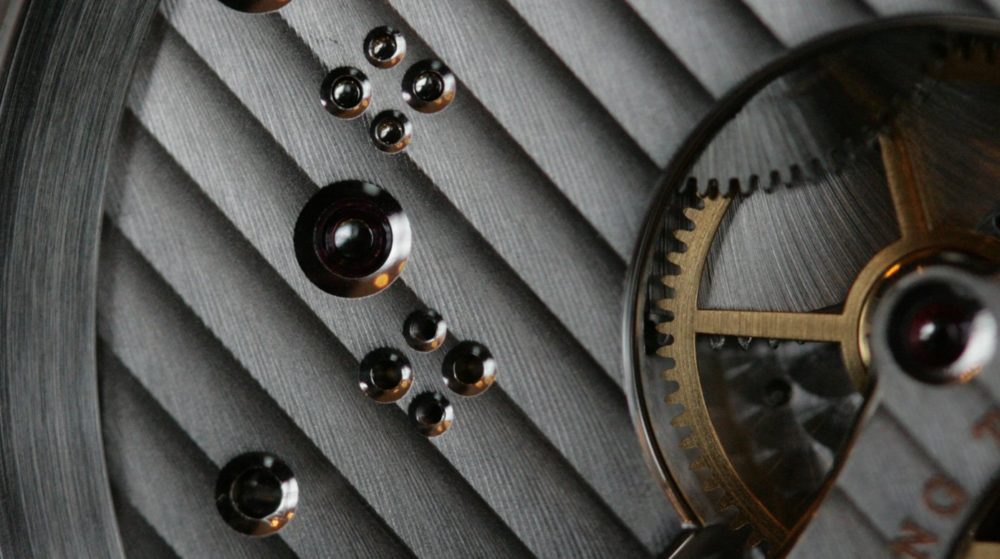

Above are examples of cote de geneve finish. It differs from a standard end mill finish and creates more depth in the surface of the metal.

On the left is a finish called Perlee which is created in a similar way to the Cote de Geneve with the difference being instead of moving the abrasive disc in lines, it is pressed into the surface to make small circles which overlap. On the Right is a polished finish.

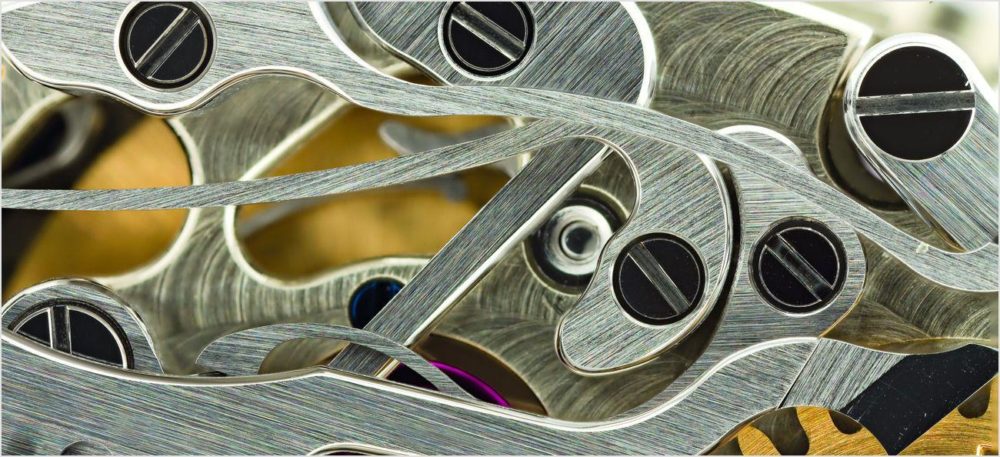

Straight and curved brushed finishes on the different layers of the internals of a watch.

For the actual construction of my project, I will either buy or make the main body of an amplifier case and remove the faceplate to replace it with the custom one with a custom layout. The minimum will be a power button, volume knob and an input select knob. My current plan is to have symmetry by placing the power button in the middle with either knob on each of the sides. Both knobs will be identical and will be made out of turned aluminum to add weight and feel to it.

A Jeff Rowland preamplifier which I am also drawing inspiration from. The finish is just a rough faced aluminum plate made by running a large end mill over and anodizing. It’s simple yet beautiful.

2 Comments. Leave new

I like the idea of drawing inspiration from the aesthetic of high end watches and think your plan seems very well laid out. Did you considered building on your clockwork aesthetic just with the form of your nobs, or also in the dynamics of the project?

I can certainly explore some more places I can incorporate the watch aesthetic into the design. Luckily we are still in the early stages of this project, so it allows for some more flexibility designing the final product.