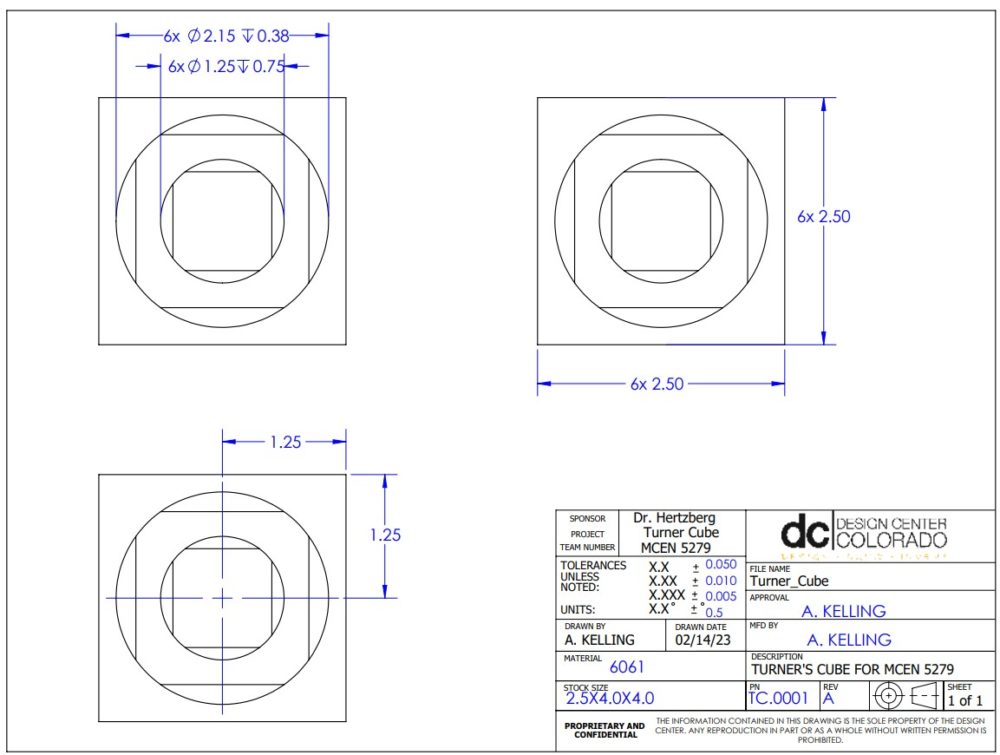

For my Upcycle project, I am making my own rendition of a Turner’s Cube out of a scrap piece of aluminum. To start, I researched Turner’s cubes online. After seeing varying designs and types, I understood the aesthetic I was going for, cubes in circles that are not free floating. I designed my cube in Solidworks. I played with several different ratios of circle size and depth of cut. I settled on a final design and made an engineering drawing.

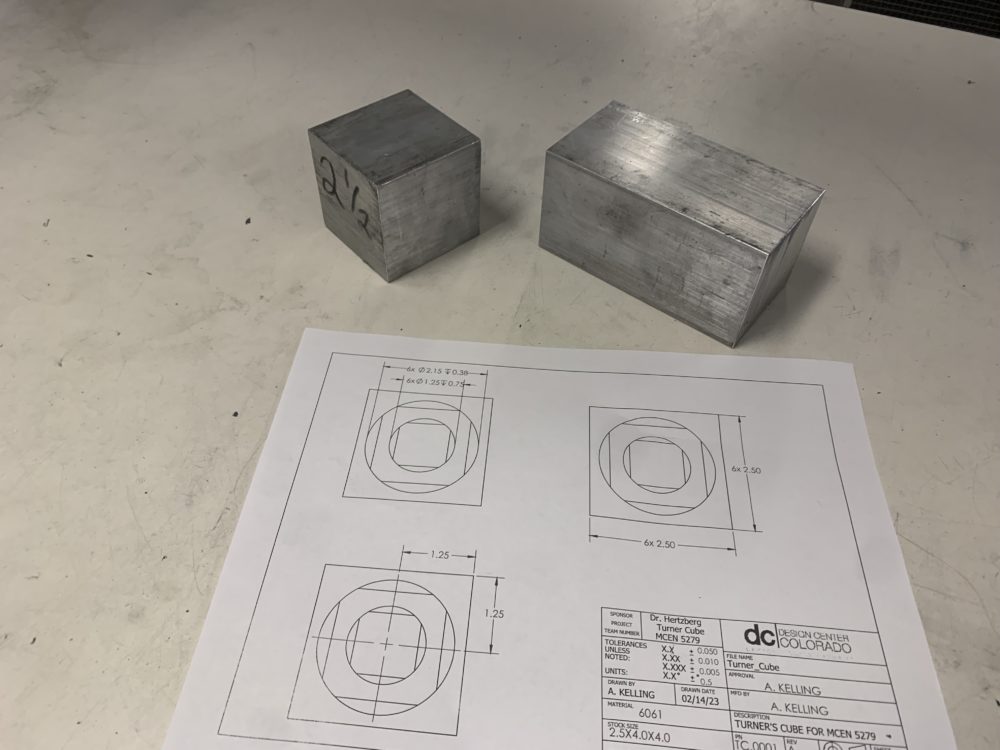

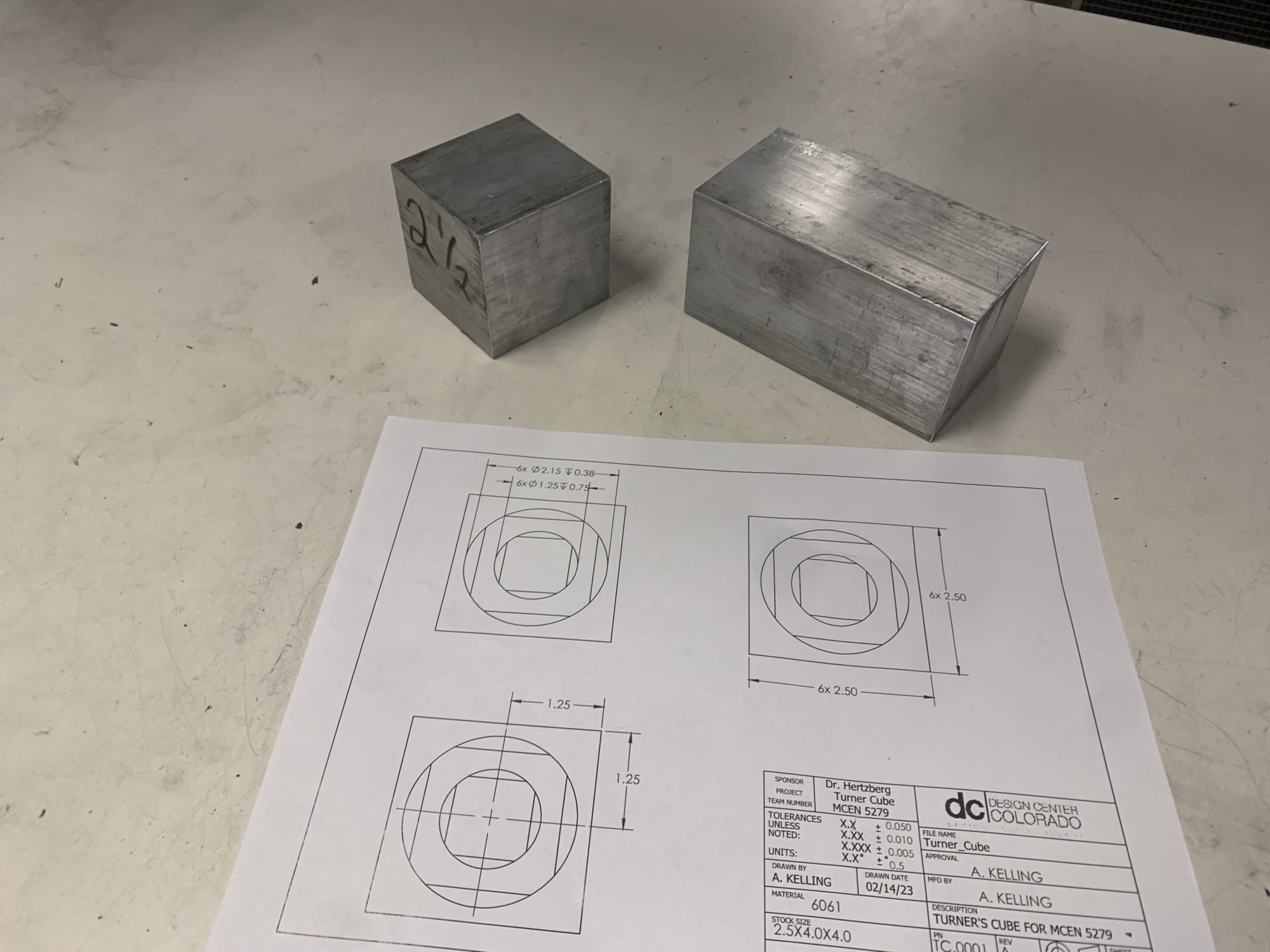

Using this drawing, I used the IdeaForge machine shop to begin my process. My steps so far include:

- Cutting barstock to length.

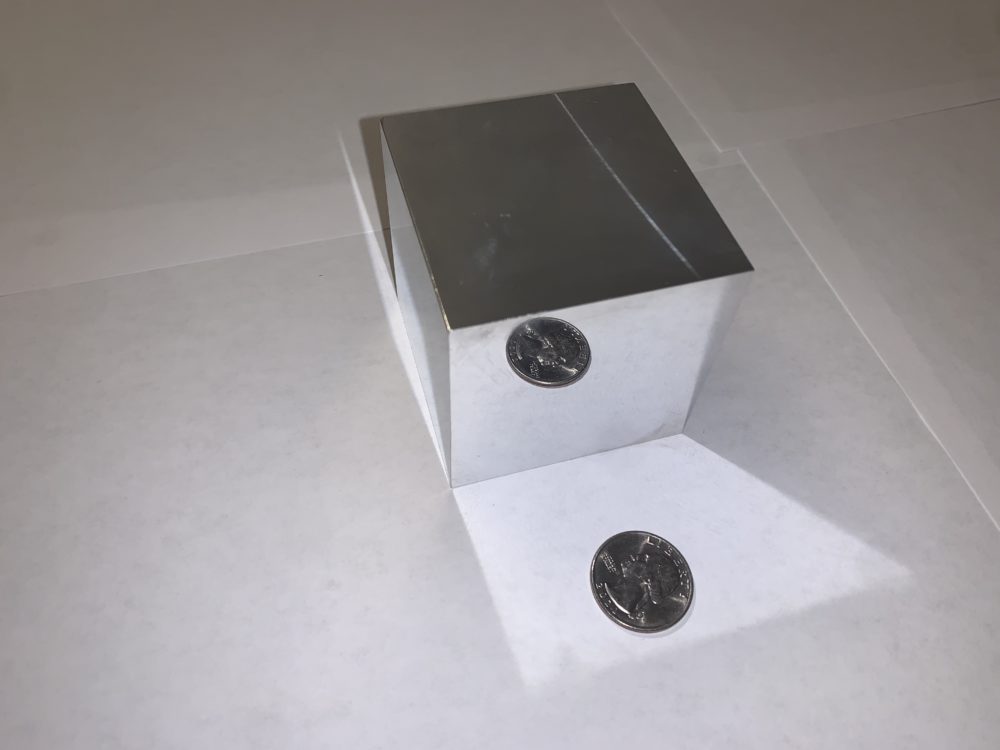

- Machine all six faces to be parallel and have an acceptable surface finish.

- Test polish a side.

- Bore four of the small holes to depth.

My work to be done to finish the project includes:

- Bore remaining two small holes.

- Bore six larger holes.

- Polish until very shiny.

So far this project has been very enjoyable. Machining is a fun and exciting way to manufacture, and I enjoy doing it. It has been satisfying to have ownership of a part and its design. I look forward to finishing it in the next week.

2 Comments. Leave new

That is looking great so far, and ought to be decent mill practice as well. Are you considering any secondary finish, or simply a polished look?

This is a great idea for a project and I’m sure it has been an excellent experience learning to machine something that complicated. I love the idea of just having it as a desk ornament and I am doing something similar in my project. How are you planning on achieving that super shiny surface finish? I think it is going to turn out great, good luck!