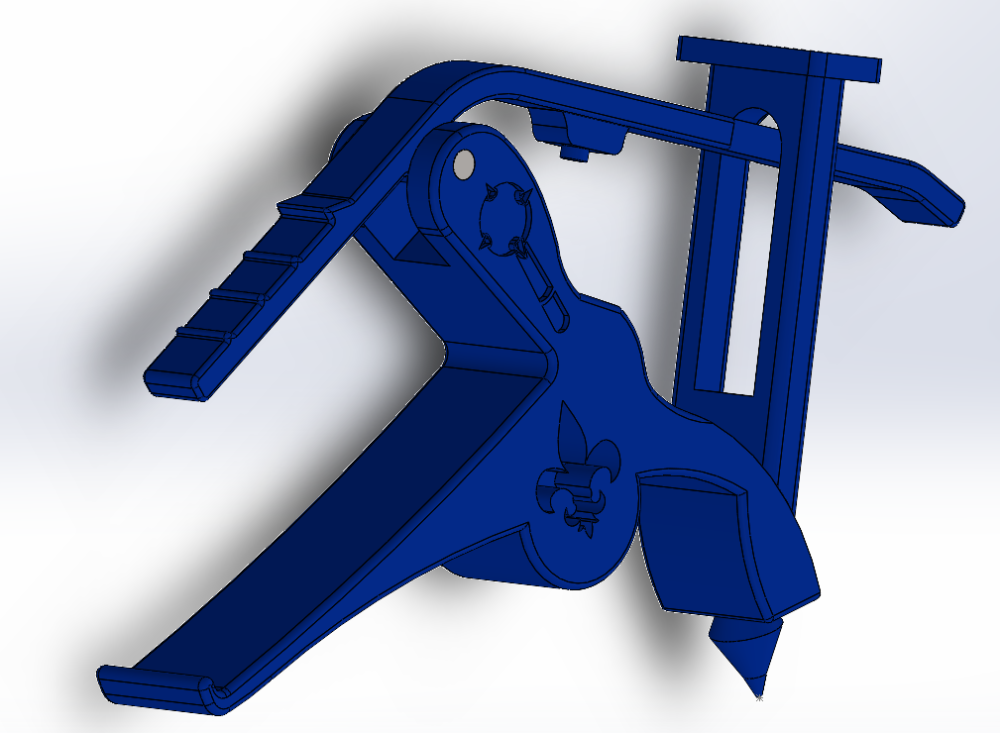

For my final project, I am 3D printing a capo. When I set out to design it the number one specification I had is that it must apply pressure to all six strings of the guitar. This is the only function of the capo, so it can’t be considered one unless it can do this. Another specification for the capo is that it must have a renaissance aesthetic in as many places as possible, except the jaw. I believe it accomplishes this because of the symbols and the renaissance gate.

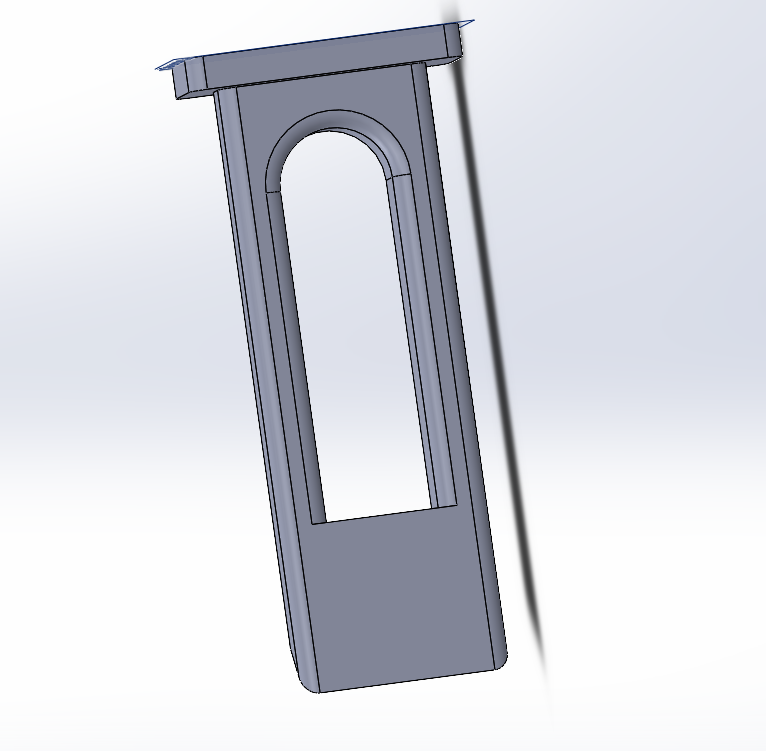

Speaking of the gate, it specifically has two specifications. The first is that it must contain the clamp lever arm within it. By this, I mean that it has to keep the lever arm from flying off the capo assembly from the spring force. The second specification it has to have is that it must stay attached to the main capo assembly. This maybe easier said then done with glue, but I am unsure of what pressures it will be under when I try to put the capo on the guitar. The last specification for the capo is both aesthetic and functional, and it has to do with the ergonomics of the assembly. The capo has to comfortable to my hand when I’m applying force to it to press it onto the guitar. Those are the top five specifications for the capo.

The top constraint that I have for my project is definitely cost. I already spent $30 on a filament roll I can’t use, so I am now very conscious of what I am spending on this project. That being said it actually doesn’t cost anything to print from the University because my parts are so small, so that helps me out in a big way. I am also constrained on time, but it is less of a concern then money. The only worry that I have is that I will break a part and the University will not be able to fabricate it in a timely enough matter for the final presentation. However, there is only a small chance of that happening. Another constraint I have is size, which helps my cost out, but hurts my aesthetic. Capos just don’t have a lot of surface area in general, and my design limits it even more. I went with having a unique lever stop for my aesthetic, instead of having sculpted molds like I wanted because it made sense with the size of the capo.

My last two constraints are similar, but both have to do with the jaws of the capo. The first constraint with this is the material of the capo itself. It is made of PLA plastic, which is not as strong as plastic used with industry capos. The final constraint for the capo is the size of the jaws. I had to base this off an existing design so that I wouldn’t hurt my guitar, but I have to base the assembly of my capo, and the aesthetic around this measurement. If I could change it to be thicker or wider, I would, but I can’t. Those are the top five constraints and specifications for my capo.

1 Comment. Leave new

I really liked the design of the capo and the easy manufacturability of it. Does it have any strength specifications?