My design has been a lot more refined since the Aesthetics & Alternatives post. I’ve finalized what materials to use, the logistics behind the entire project, and how I want to achieve my aesthetic.

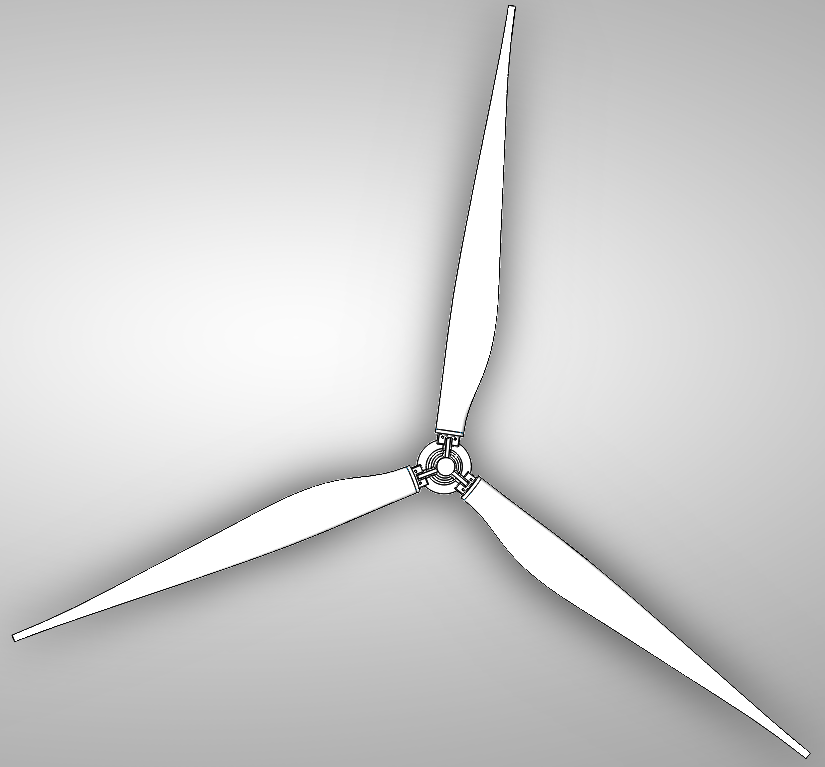

There are 3 main aspects of my project: the base structure to hold the turbine blades, the turbine blades themselves, and the motor integration with the blades/base.

I’ll start by talking about the base structure. Initially, I was planning on making this base structure out of wood to ensure that it could actually support the blades, but after realizing that wood was going to be quite difficult to mold into the shape I needed and that the wood was not ideal for the minimalist aesthetic of the whole system, I decided to move away from the wood idea. Next, I thought about using metal for the base, but again, without having the proper equipment or access to a machine shop, It was going to be basically impossible to turn some metal into the shape I needed in the small amount of time I had to complete this project. All these decisions led me to a PVC-designed base that would be easier to handle than the metal, be as sturdy as the wood, and match my minimalist aesthetic significantly more.

Next, I’ll talk about the blades themselves. For wind turbine blades to work in spinning with the flow of wind, I needed to cut them into specific shapes that had a bow on one side and a straight edge on the other so that the wind would deflect the blades in a certain direction. This meant I needed to most likely cut some material into the shape of blades. There was another idea to possibly get an old fan, use the blades that were included with the fan and turn that into a turbine, but after searching the internet, I quickly realized that getting the size/shape was really tough since I needed a permanent magnet DC motor and most fans aren’t equipped with these, so for me to be able to use the blades of an old fan, I needed the blades to have an opening that exactly fit the motor I was planning on using for the project and this was really difficult to do. All this led me to believe that I need to make the blades myself. Next came the question of what material to use for the blades. I needed to use something sturdy and fairly easy to cut and was water-resistant. This threw out metal and wood leaving me with PVC.

Finally, I’ll talk about the motor integration with the whole system. I have not finalized how to integrate the motor completely as of now, but I believe it’s going to be some sort of wooden/pipe structure that I will attach the motor to.

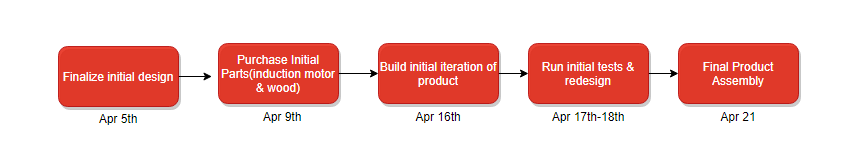

Logistics-wise, I’ve created a timeline as shown below to ensure I get all my parts/complete the project on time.

Presentation Video: https://youtu.be/_0ygNoX1yHM

Sources

2 Comments. Leave new

Sohan, I like your idea for this project and where you are going with it, especially your choice of PVC instead of wood. I think that PVC lends itself to your aesthetic a little more, and it sounds like it will be the easiest to work with. You mentioned that you also plan to have the blades be made from PVC. How do you plan on achieving the proper shape of the blades? I am excited to see the end result of this project at expo!

Hi Sohan, I know I attended the critique of your design preview already, but I wanted to reiterate how I think this design has a lot of potential to be a nice homage to the engineering side of design and how the overall aesthetic seems really cool. The PVC is also a material that there’s tons of resources for, so there should be lots of background in case you need it. Nice job!