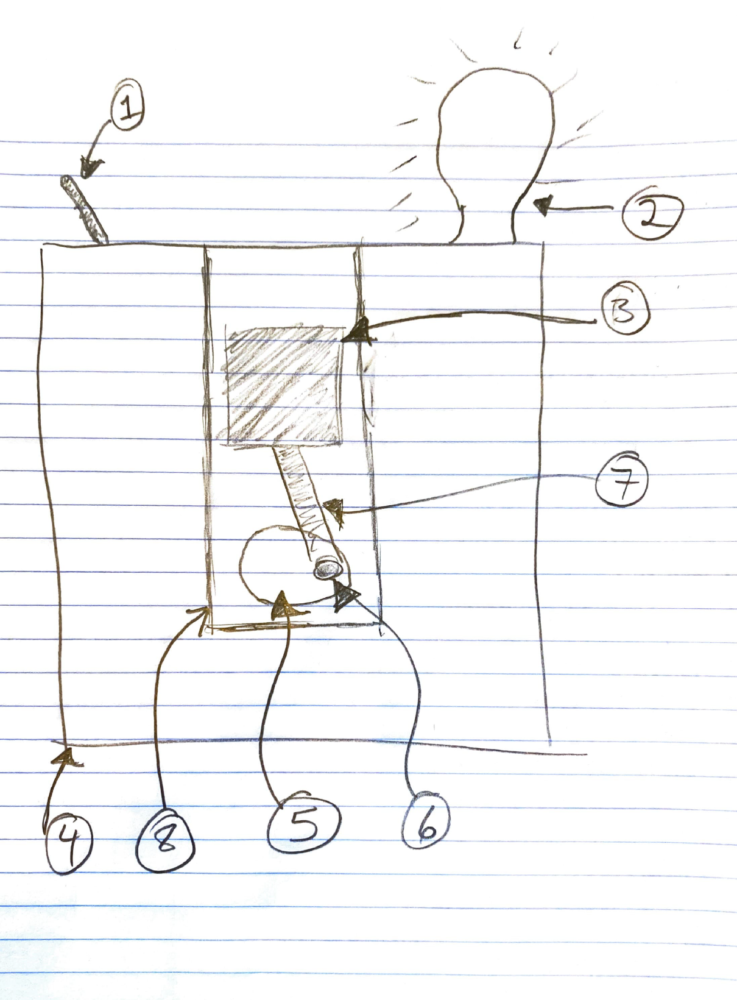

For this blog post, I will be outlining some of my top project constraints and specifications. Due to the open-endedness of this project, much of these constraints and specifications are open to change as I see fit. Below is an image of the front view of the design for reference if you haven’t read my previous posts.

The parts for the associated labels above are as follows:

- Spark plug switch

- Light bulb

- Piston

- Overall lamp base

- Cam attached to the motor

- The connecting point between 5 and 7

- Connecting rod

- Extruded edges to hold piston vertical.

The specification and constraint lists come as a result of having completed the design preview for this project:

Top Five Specifications:

- The product should not exceed a 4″x4″x8″ volume. Since this lamp is expected to go on my desk, I don’t want it to take up any more space than it needs to.

- The piston should not be cylindrical. Since this project is going for a minimalist aesthetic, the cylindrical profile of the piston is not necessary. I have designed the piston to act as a rectangular prism that moves up and down.

- Assembly: All mating components in this project should have connections that are not visible from a front or top view of the lamp.

- Lack of readily visible complex design: Since I’m going for a minimalist aesthetic for this project, it does not make sense to have complex parts that are readily visible. I want it to be as low-profile and sleek as possible.

- I want the light and the motor to both be activated by a single switch. This is accomplished by using a sparkplug that will activate the switch on an extension cord that powers both the fan motor and the lightbulb.

Top Five Constraints:

- Time: This project needs to be completed by April 28th or earlier. Currently, I’m on track to finish early, but I need to maintain my pace in order to ensure that the timely process of 3D printing doesn’t take up too much of my schedule.

- Electrical Cohesiveness: In other terms, I need all electrical components to work together successfully. Since I have all of the components, as of today, I can test this in the upcoming week.

- Mobility of Moving Components: This is a tricky one since almost everything for this project will be 3D printed. I can’t rely on the 3D printed parts to act as bushings, thus, I have found links for tutorials to learn how to design and print bearings. A link for the video can be found here.

- Modern/Minimalist Aesthetic: This constraint is driven by the selection of materials as well as component design. I want all components to be made out of a choice of two different 3D printer filaments: white and orange. This will ensure that the color scheme matches a minimalist aesthetic. Additionally, components should not have an overly complex design in order to ensure sleekness.

- Cost: As of right now, the cost of this project should not exceed $40. Should I need to get some parts outsourced (for example, the base of the lamp might need to be laser cut out of acrylic or 3D printed elsewhere), I should maintain that my project budget does not exceed $100.

Please let me know what you think and if you have any suggestions!

Sources:

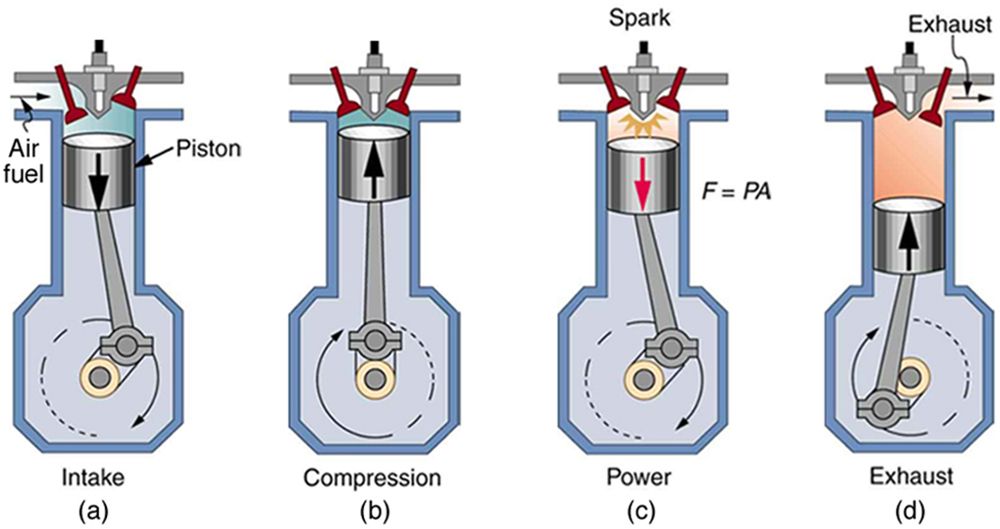

Featured Image: No copyright violation intended. This is not my image.

3 Comments. Leave new

Very Cool!

It could also be an interesting Idea for a clock.

You might want to change your explanatory graphic to a two stroke.

Hey Chris, I like that you chose specs that were either quantitative or like yes/no checkboxes; I think that sets you up for hitting those targets easily, it’s important to be specific and I think you recognize that! It sounds like none of your constraints are deal breakers for your project either, so that’s great. To me it sounds like the moving components one might be your most difficult challenge, but it sounds like you’ve got a good plan of attack for it! Good luck- I am excited to see how this turns out.

Hey Chris, its great to see your project all planned out. I think your specifications and constraints are all manageable and the more pivotal ones, it seems like you have plans for. I am really curious to see how those 3D printed bearings turn out. The final project will look amazing!