With finalized plans for my final project design and some good strides in fabrication, I’ve been able to think quite a bit about the key specs and constraints of the wall plant wheel that I’m making. Five specs of my project are as follows:

- Outer dimensions

- Number of plants to hold

- Smooth / uniform rotation

- Locking mechanism

- Weight

The first spec listed, outer dimensions, is a key spec of my plant wheel. I want the wheel to take up a decent amount of wall space in my dining area, which is currently the least decorated room in my home. The overall outer diameter of the wheel will be approximately three feet, which should provide sufficient spacing between plants to avoid collisions during rotation, while nicely filling wall space.

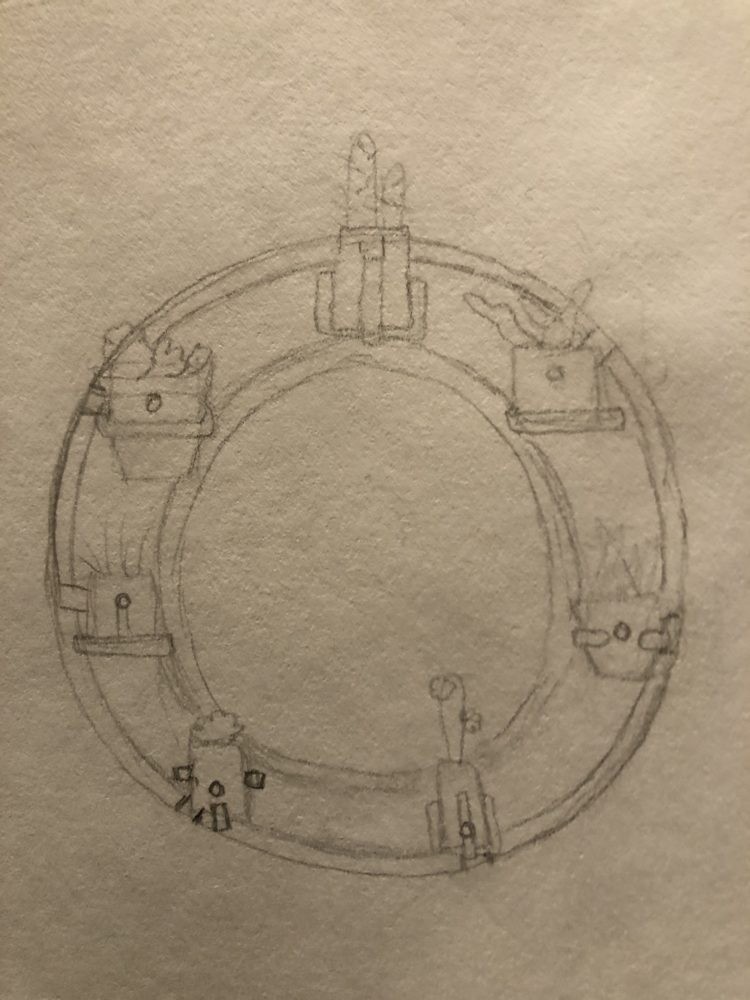

For the second spec, I’ve designed the plant wheel to hold seven different plants. I want to use an odd number of plants to avoid having the final product look too symmetrical. Odd numbers seem more dynamic to me, which applies to the primary requirement of this project: to create a dynamic artifact.

This brings me to my third spec: the ability to rotate smoothly and uniformly. Rotation of the outer wooden circle around the inner bike wheel is the key dynamic element of my project. Being able to rotate smoothly and uniformly is essential to the overall stability and success of the final product.

A variety of plants, each of a different size and weight, will be used, meaning that the overall weight balance of the plant wheel will not be equal throughout. This will likely result in one plant always being positioned at the top of the wheel, as the heavier plants will rotate to the bottom. In order to change or set which plant will be at the top of the wheel day-by-day, a locking mechanism will be implemented, which is the fourth spec listed.

Finally, the weight of the final product is the fifth spec I considered in designing my plant wheel. Because the plant wheel is meant to be mounted to a wall, it needs to be light weight enough to successfully hang on the wall without applying significant force or causing damage to the wall. As such, I am implementing a 20 pound limit on the final product.

There are also five key constraints of my project, including the following:

- Rental home

- Mounting method

- Equipment / tools

- Plant sizes

- Cost

A big constraint of this project stems from my current living situation. I am renting the townhouse that I’m living in, so I need to ensure that the plant wheel can be successfully and stably mounted without causing too much damage to the wall.

This leads to my second constraint, which is a mounting solution. I want the mounting solution to minimize damage to the wall, while also staying somewhat hidden behind the plant wheel. Thus, I am limited in the size and implementation of a mounting method.

Another constraint is my access to equipment and tools to fabricate the plant wheel. I still have the tools that I borrowed from the university’s wood shop for the upcycle project, which have been very useful in the fabrication I’ve completed thus far. However, I do not have access to a proper drill to apply uniform holes in their necessary locations. My fabrication plan is constrained overall by not being able to access some of the larger equipment in a legitimate wood or machine shop.

A fourth constraint is the size of the plants I’m using. I selected specific plants to help minimize weight and to minimize the amount of effort I’ll need to put into caring for my new plants. The plant sizes I selected are constraining the overall outer dimensions of the plant wheel, as I want the plants to be spaced enough not to collide with each other during rotation, but I don’t want there to be too much space between plants such that the final product looks underwhelming.

Finally, cost is somewhat of a constraint. Attempting to make the plant wheel on a budget, I have mostly tried to buy materials from Eco-Cycle. In doing this, I’ve been able to find some fun, unique materials to use, but there’s a lack of uniformity in some of these materials, which has put some design and fabrication constraints on the project.

With a clear understanding of my design specs and constraints, I’m in good shape to finish fabricating my final project on time and in line with my vision for a well put together plant wheel.

2 Comments. Leave new

Hey Natalie

I think you’ve done an excellent job outlining your specifications and constraints. It’s awesome to see the progress you’ve already made on your project and I’m excited to see the final result. I’m also concerned about how you’re going to mount the wheel to the wall while minimizing damage. What is your plan to accomplish this?

Hi Natalie,

Great job with your specifications – it is clear that you have a well-defined path towards successfully completing this project. I was excited to see images of some of the components laid out as they will be assembled. Do you see any potential issues with being able to rotate? And, if some plants are heavier than others, do you expect a steady-state configuration and is that okay with you?