As those of you who read my blog post last week know, I have decided to construct an air intake system for my car that consists of an intake tube and air filter enclosure. I am aiming to make a design that simplifies the engine bay while also conforming to the minimalist aesthetic. However, I want to add features that are reminiscent of the other components in the engine bay like the fuse box and the valve cover on the engine. I feel that by designing my airbox with these constraints in mind, it will create a simple elegant look, almost as if the manufacturer intended it to be there. The airbox can be seen in the cover photo, it is a large black plastic box with a red air filter inside.

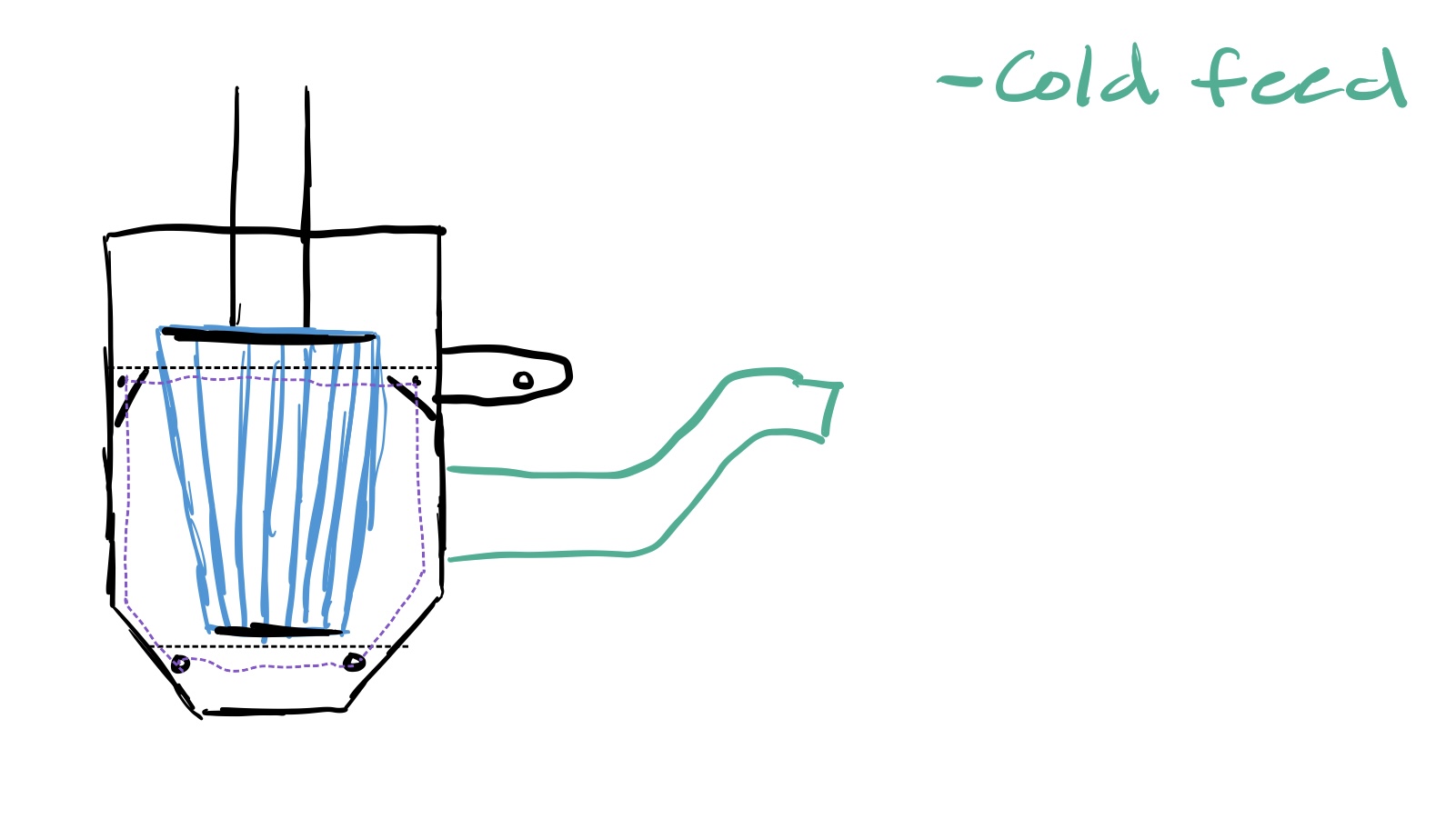

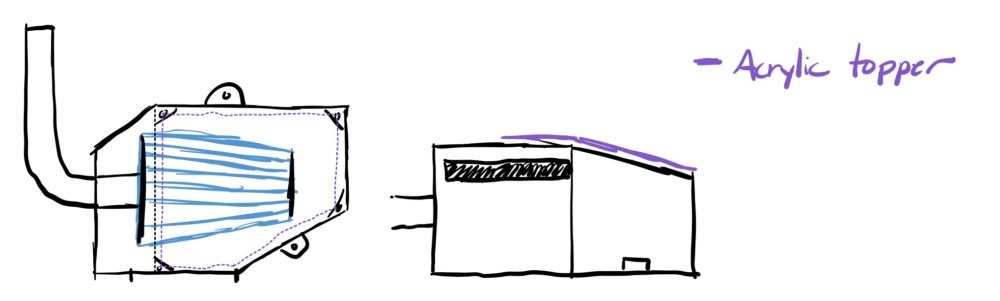

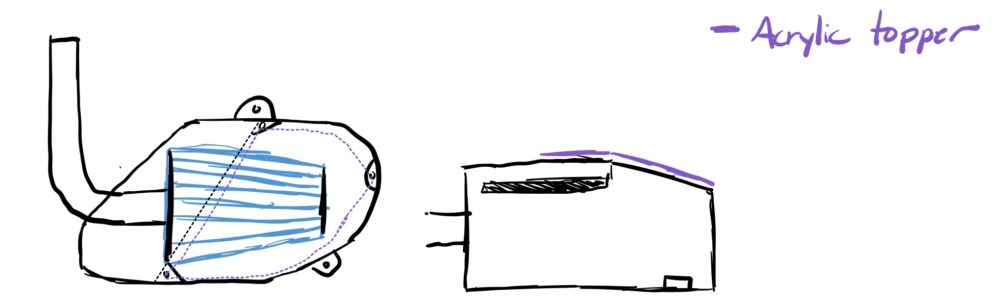

I am limited by the available space I have to work with and by the size of the air filter I have decided to use. Otherwise, I have some flexibility as to where I place the air filter enclosure and how large I make it. I have a few design ideas that conform to these constraints but would look dramatically different in the engine bay. All three of my ideas involve a top cover made from a transparent material, likely acrylic, to show off the filter inside. My first design fits in the same location as the factory air filter enclosure but is relatively small and the space that it must fit into will greatly affect the aesthetics. This is the easiest intake system to make because the intake tube would be the shortest and the enclosure would have the simplest bends. However, this is my least favorite design because I feel like it would be difficult to apply an appealing aesthetic to it and there is some empty space very close to this area that could be utilized.

My second design incorporates a much longer air intake tube with a 90 degree turn in it. This design has the advantage of being farther away from the engine and therefore the radiant heat coming from it. It also has more available space to make a larger enclosure which would be beneficial for the airflow through the air filter. If you examine the cover photo you will notice a black plastic cover panel towards the driver side of the car that can be removed to accommodate the larger airbox. This is my favorite design because I think it matches the existing aesthetics of the components that are already in place while also improving performance.

My final design is a derivative of the previous design in that it fits in the same space and utilizes the same air intake tube. This design utilizes a lot more curves and has a more organic shape. While I do like this design, I think it would be more difficult to manufacture and it might not match the rest of the vehicle as well. I can also use some tricks to combine some features from this design into my second one like grinding down the welds or bending a single piece of metal in order to give the enclosure a smoother more finished look. My next step will be to remove the current intake system and 3D scan the engine bay so that I can start the design process in CAD and determine the best design. If you have any suggestions or prefer one design over another, let me know in the comments below.

Cover Photo: https://www.reddit.com/r/Volvo/comments/gb9sv4/cleaning_up_the_engine_bay_stage_3_s60r/

(Other photos are my own work)

3 Comments. Leave new

Very excellent idea. I am also very interested in engines. visit this for reading more about engines https://mechanicalboost.com/fuel-pump/

Zack, I am not a car guy, but I think this is a great idea for a final project. I think that the second option matches your aesthetic the most, and I appreciate that it will also have a functional purpose and boost the performance of your car. What are you looking for in the 3D scan of the engine bay when you make your final decision on the design?

Zach, as a fellow engineer and car guy, I am super excited to see where you take this. I definitely did not expect that anybody would be designing their own intake for this project, and I think it’s an awesome idea. As far as your three ideas, I think I like the second option the best. It feels like it has a good balance of form and function, and will hopefully will be a bit easier to do than the third option. How are you planning to do the fabrication? Are you planning to do the cutting/bending/welding yourself? If you plan to use aluminum, will you be doing the welding? I know from experience that TIG is pretty tough. Overall, I think this is an awesome idea that could turn out very cool, but may require a lot of trial and error and tough manufacturing processes.