One of my favorite hobbies is dirt biking – I ride a KTM 300cc (seen in the featured image) two-stroke that has been an absolute blast to ride for the past several years. One of the aspects of two-stroke engines that make them so fun is the simplicity of the engine itself. A two-stroke engine, as the name suggests, has two strokes to provide power to the transmission: an intake/compression stroke and an ignition/exhaust stroke. Because of this, two-stroke engines have an extremely simplistic design – a mock-up of the two-stroke engine cycle is shown below:

My initial ideas lead me to want to replicate this motor in some way for a desk lamp. I’m still in the brainstorming process, but I think a desk lamp would be the perfect opportunity to model this while having a cool dynamic desk toy. First off, however, I want to make this engine look more similar to the one on my dirtbike. My engine does not have the heat sinks seen above, as it is liquid-cooled. I’m wondering if I can find a cheap, liquid-cooled two-stroke engine to make this from – it would be so cool to have light bulbs attached to where the coolant hoses enter the engine. An example of coolant hoses coming out of a two-stroke engine is shown below.

Obviously, I wouldn’t necessarily want the bulkiness of having an entire engine on my desk, so I’ll have to decide whether I want to make some pieces of this out of metal, or, alternatively, 3D print custom-designed parts. I’m personally leaning towards 3D printing my own custom-designed parts to get the dimensions exactly how I’d like. I can, however, use heavy duty hoses like those seen above, to hold wires for the lamp.

The crux of this project, to me, is having both a functional desk lamp and a cut-open mockup of a two-stroke engine that is actually able to rotate. If I choose to have one part of the lamp that is not custom-designed, it’d likely be a piston from a real engine. Although this project was slightly inspired by the upcycling projects, I think custom-designing this lamp can allow me to express creativity regarding what aesthetic I’d like to showcase. I can go the route of a steampunk-esque route, using lots of gears and fine details, or I can take a minimalist approach, which seems more inspiring to me. The minimalist approach seems more useful to me since I am designing the parts, it’s easier to design parts that are less complex, but focus on the material used.

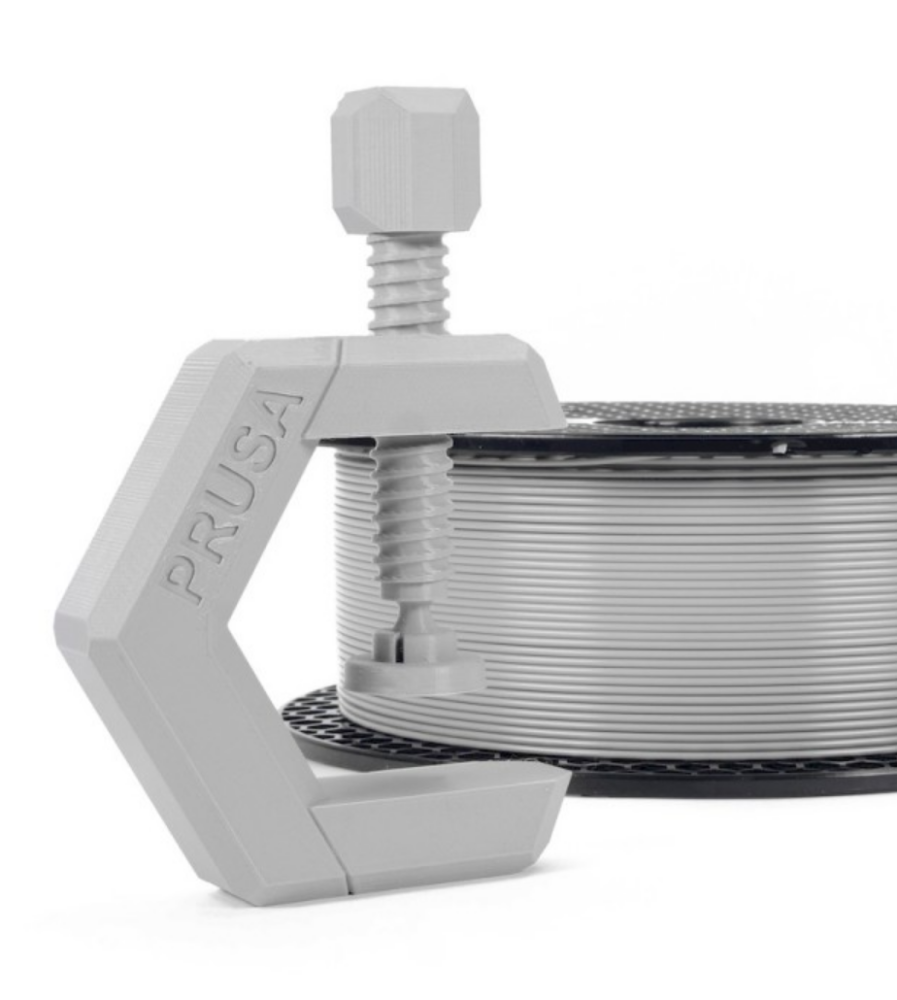

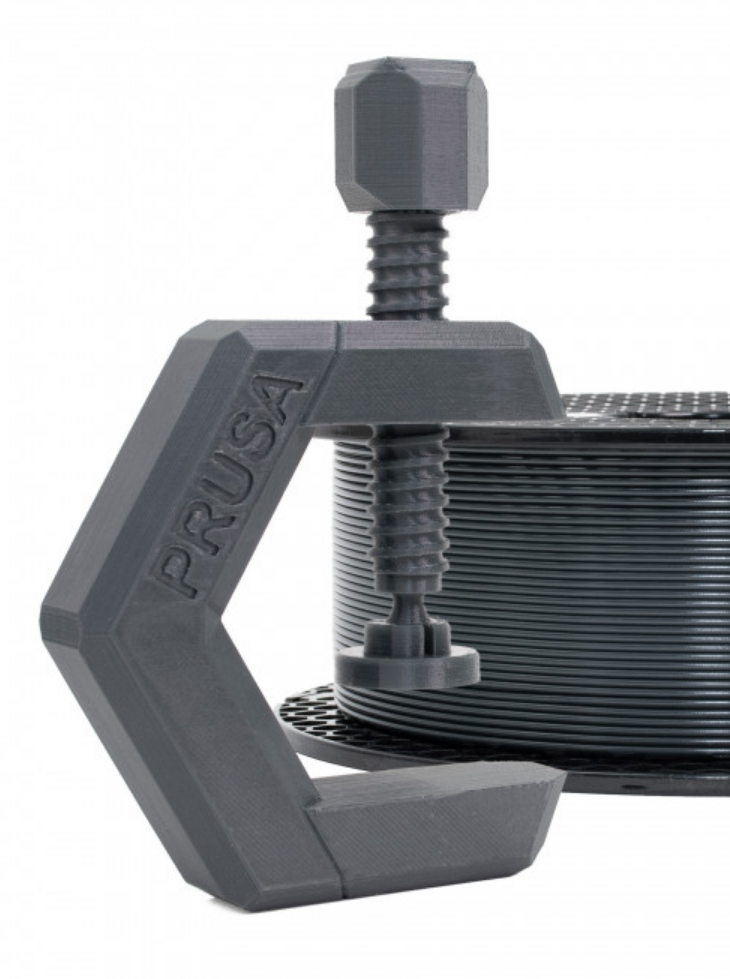

Regarding material, I have tons of different 3D printing materials: white PETG, orange glass-filled nylon, black nylon, etc. I’d love to explore more 3D printing materials that could give the engine a simple, yet beautiful appearance. An example of some materials I’d consider using are from a famous 3D printing company, Prusa3D, which makes some beautiful filaments such as Galaxy Black, Urban Grey, and Anthracite Grey. Examples of those colors are shown below, in the order in which they were presented.

I feel that utilizing some of these colors, using simplistic design, can capture the beauty of aluminum cast parts, such as engine cylinders used in two-stroke engines. I think two ambitious goals that I can achieve are: having a moving piston when the lamp is activated and using a sparkplug as the lamp switch. I’m completely open to suggestions for what else to build on for this project.

Sources:

Featured Image: Image taken by myself

3 Comments. Leave new

Hey Chris!

This seems like such a great idea, I love the idea of the engine lamp. This idea almost makes me think of a steampunk sort of aesthetic, which is super cool and unique. I was wondering if you have considered some things about the light that the lamp projects. I think that whatever lighting you end up going for will have a large impact on the overall aesthetic of the piece (i.e. yellow, white, LED, blue…). I was thinking it could be potentially interesting to implement some color changing LED’s or choose a color of bulb that really reflects the aesthetic you’re going for. Thoughts?

Hey Chris, this is a super interesting idea. One of the questions, I had was how are you going to ensure the motor can rotate. I know 3D Printed shafts and holes can often time not fit as in CAD. Do you plan on using other Mechanical Components like bearings? I ask because I also plan on having a rotating 3D Printed component in my project and am curious as to what your solution will be.

Hey Michael, great question. I believe I will be using bearings for this to ensure rotation. I’ve printed parts to act as bushings before and they just don’t really work that well. One of my initial developments on this should be to determine the tolerance on my printer to ensure a press-fit between parts interfacing with the bearing.