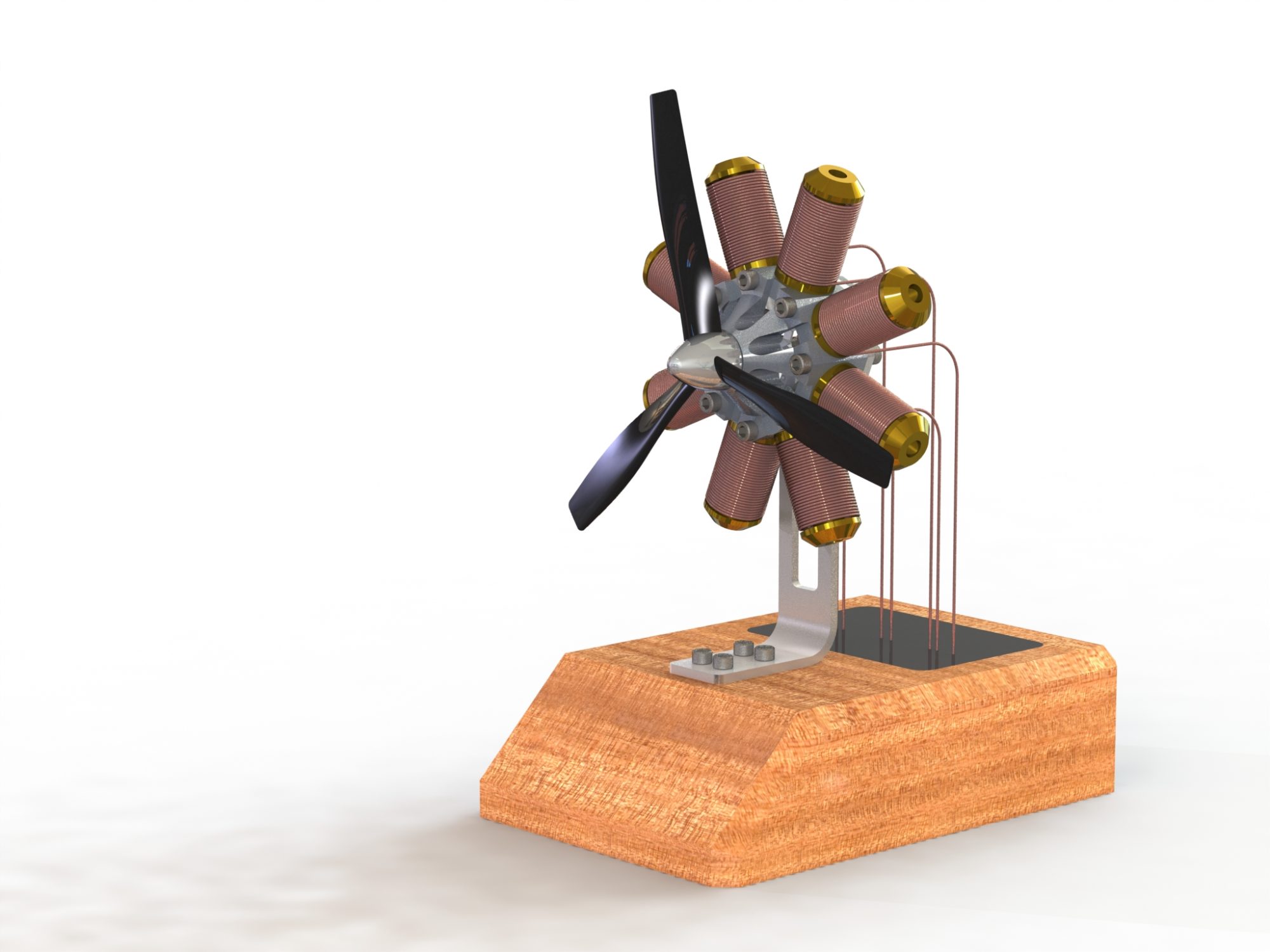

For the final project, I decided to make a radial engine powered by 8 solenoids. Before COVID-19 restricted our ability to use campus resources, I planned to machine all of the custom parts for my project. However, once we began quarantine, I settled on making a few high quality renders and motion studies of my Solidworks model.

The aesthetic I was going for was steampunk. Steampunk usually features a lot of metallic finishes such as steel, aluminum, copper, and brass. Objects that fit this aesthetic also generally have a lot of exposed mechanisms and moving parts. Both of these features went well with the choice to machine most of the parts of this project. I also wanted to make the engine appear to have pipe and cables connecting the parts to further bring in the steampunk aesthetic So, as shown in the render, the input wires to the solenoids are designed to be a heavy gauge so that they could be bent and held in place.

The top 5 constraints that I had for this project were:

- Must fit some of the qualities of the Steampunk Aesthetic

- Must be machinable geometry

- Require little to no CNC (so that I minimize my burden on the machine shops)

- Minimize Cost (Raw stock is between $150 and $200). The design was beginning to get expensive

- Must actually function

So far, all of the design is able to be manufactured with manual machining techniques and I managed to get the overall cost of the project below $200.

Here are the videos of the working CAD model

1 Comment. Leave new

Ryan,

Your project is very cool! As someone that loves aviation, I think this project is awesome. How does the engine cycle? Is it based off of a magnetic field created by the solenoids? Also, where did you get the Idea for the radial engine?

As far as aesthetics go I think you nailed it. Nothing beats a big radial