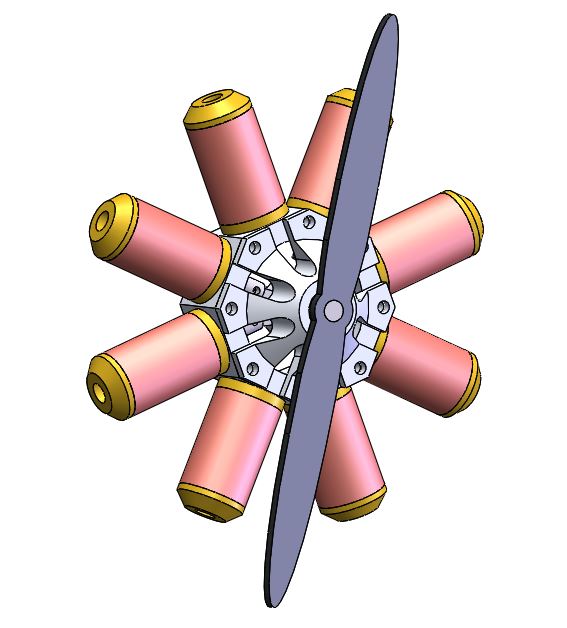

Aesthetic: This is the most obvious constraint of my project since it is for this class. My aesthetic is steampunk, So I would like the design to feature metallic finishes and exposed mechanisms.

Manufacturability: I would like to make as many of the parts of this project in the machine shop as possible. THis means that the parts must be designed such that they are machinable with conventional machining techniques (i.e 3 axis milling, lathe, saws, etc.).

Minimal CNC: Since this project is already heavy on the machining, I would like to minimize the resources that I would be taking from the machine shops. In particular, I would like to use little to no CNC so that I don’t need to take time from either Mark or Greg since they would have to create the CAM and g-code.

Cost: The cost of all of the raw stock adds up quickly since I need it in some less common shapes (Raw stock is between $150 and $200 so far). On top of this, I need to order fasteners, bearings, shaft material, etc. I definitely need to keep material cost in mind throughout the design.

Functionality: Finally, I would like to see this actual function. Ultimately, this is the main point of doing this project for me.