This post is designed to summarize my final project from the beginning, so if you did not read previous posts, this should give you a clear idea of what I am doing and how I am doing it.

For my final project, I decided to make a coffee capsules holder for my Nespresso original coffee machine. The reason I decided to do this particular project is because I have been wanting to make a coffee capsules holder before I signed up for this project, so I took the opportunity to hit two birds with one rock.

The following describes the general steps I have gone through with this project with more details under each step:

-

Step 1: Brainstorm for the project I want to make

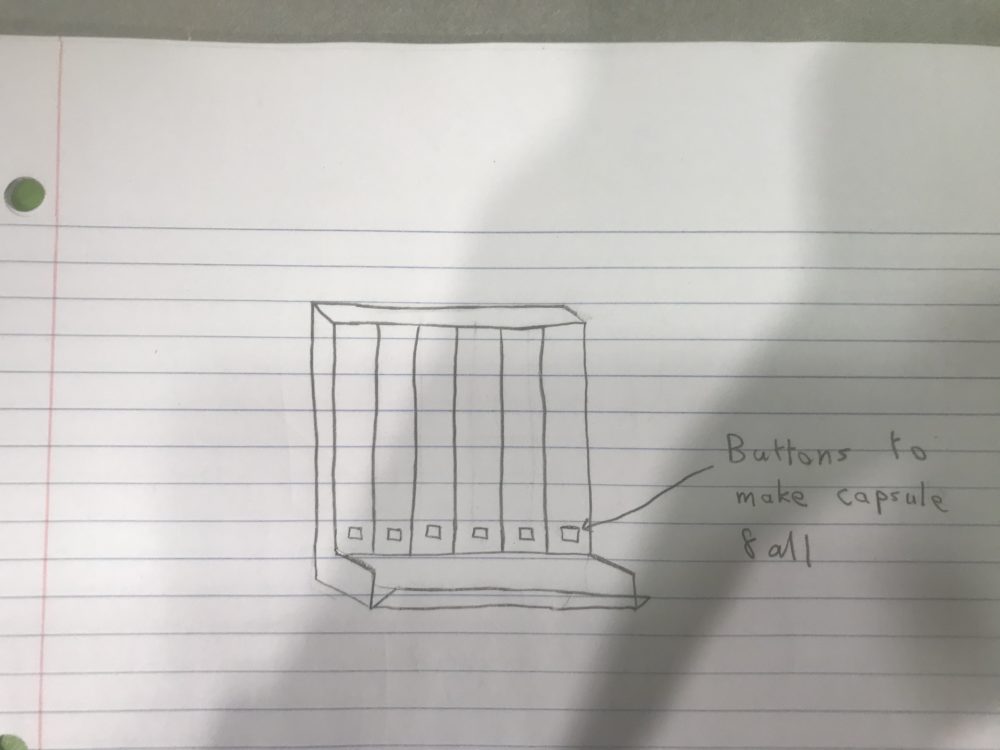

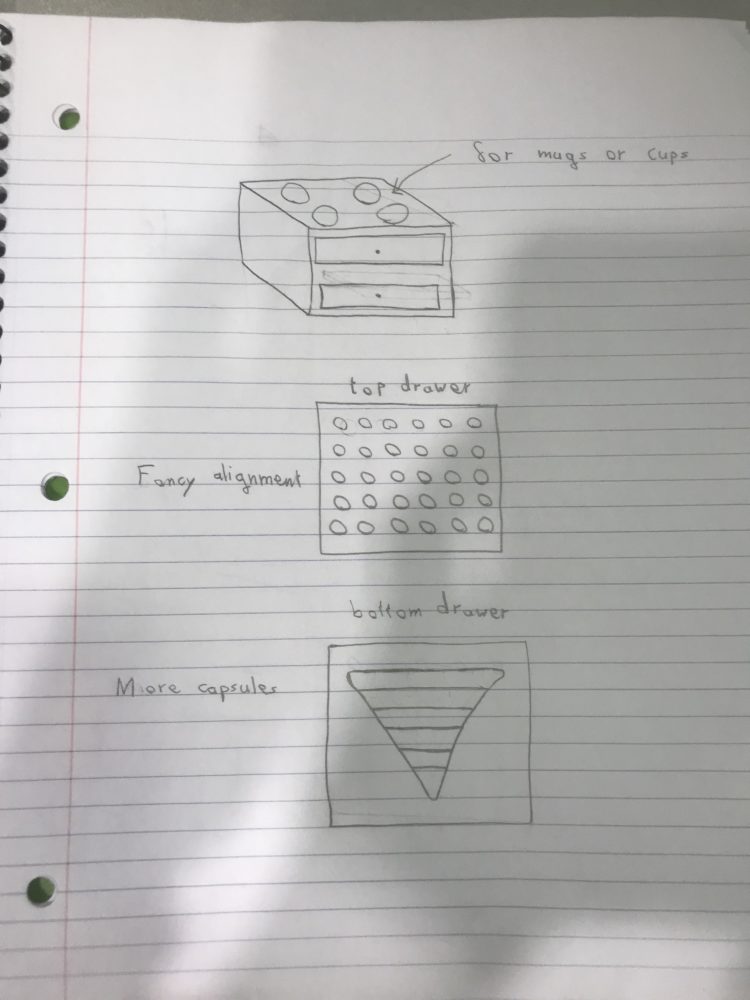

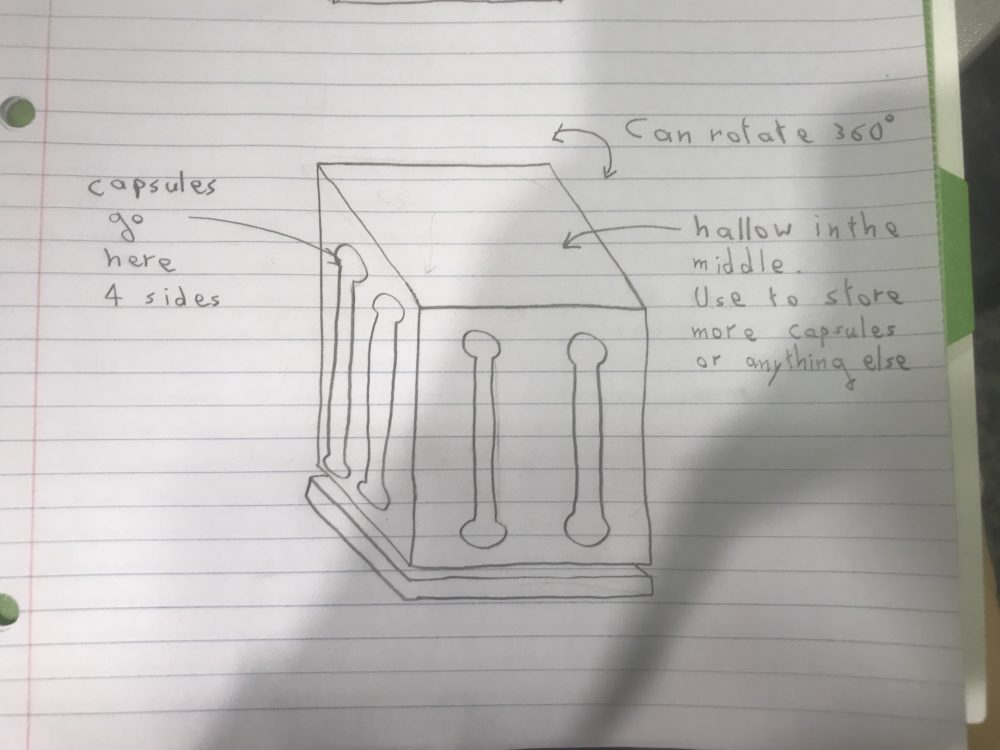

This step is probably one of the most difficult one as there were almost no restrictions on the project aside from containing a movable part, which meant that we had the opportunity to make literally anything we wanted. It took me few weeks to decided on the idea and then about a week to select a specific design among 3 different preliminary designs. The following are the 3 designs I initially had:

-

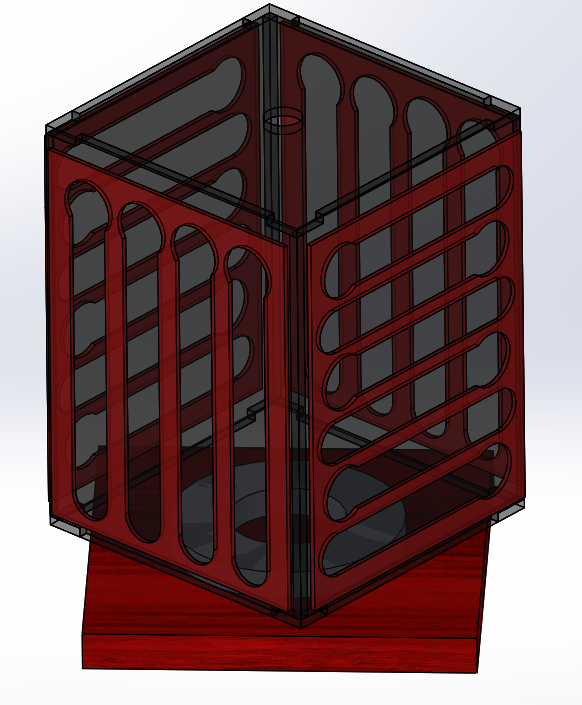

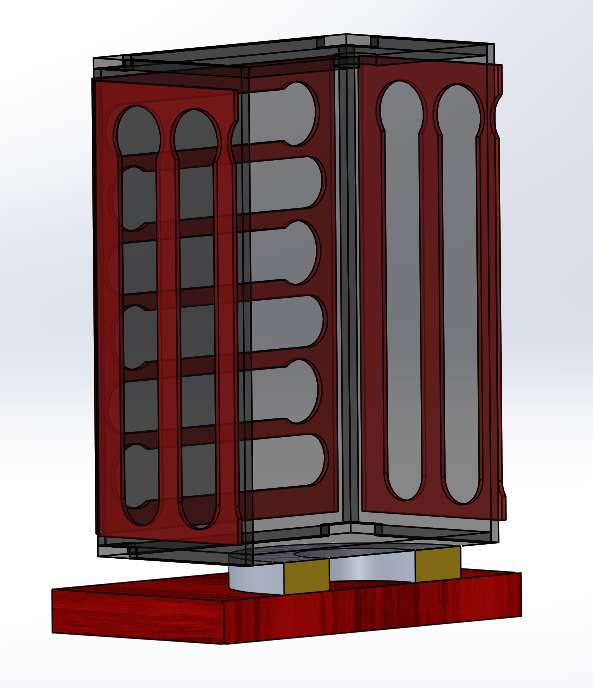

Step 2: 3D model the selected design on Solidworks

This step was relatively easy once I had a clear idea in mind. Of course, I did not get to the final design from the first trial, so I had to reiterate my design until I was completely satisfied with the final aesthetic. The aesthetic I was going for is to have the holder symmetric, modern, and sleek.

-

Step 3: Purchase the essential material which is the acrylic and lazy susan bearing

Due to the COVID-19 pandemic, I had to rush through purchasing my acrylic the last Thursday of classes so I can laser cut it on Friday which was the last day the ITLL was open. Luckily, I was able to finish these steps before the campus closure. In addition to that, I still do not know why, but I purchased the lazy susan few weeks ahead of time just to see how it looks, which turned out to be in my advantage. The reason lazy susan was essential is because it has several holes that needed to be measured exactly so I can laser cut these holes on the bottom acrylic piece.

-

Step 4: Laser cut all acrylic parts

This step was straightforward since I already had the material and design ready in advance. Although this was an easy step, it took some time to wait on all parts to be laser cut properly.

-

Step 5: Purchase a raw piece of wood and cut it to size

This step was done after campus closure, but thanks to Prof. Hertzberg suggestion for an open wood shop near Boulder, I was able to get a fine piece of wood to use in my project.

-

Step 6: Ensure all parts fit together properly, purchase the remaining material online, and finalize the wood piece

Once I had the acrylic cut to size, lazy susan, and the wood piece, I had to ensure everything fits together so I do not get stuck at the end of the course with an unfinished project. When I was certain that everything would work perfectly, I then purchased the fasteners, nuts, spacers (to eliminate interference between the fasteners and the wood and acrylic), and magnets online, along with borrowing paint, wood stain, brushes, syringes, and acrylic cement from the ITLL to be able to finish the project.

While waiting on the online orders, I was able to finalize the wood piece by drilling tapped holes for the lazy susan, staining the wood, and painting it with double layers to get the finish I was aiming for.

-

Step 7: Assemble everything together temporarily after all the online parts have arrived to present it to class

Unfortunately, with the current situation going on around the world, I had to travel back to my country few days ago. As a result, I decided to not assemble my project completely (permanently) as it would increases the possibility of it breaking during the shipping. Therefore, I have made an assembly that clearly shows how the final product would look like minus the final touches.

The assembly I made is what the project should look like at the end except the following steps that I delayed for the purpose of properly shipping the project:

- Need to peel off the other side of acrylic (brown color). Did not do it so the acrylic have minimal scratches while handling.

- Note: the black acrylic is transparent (similar to the CAD model) but cannot be seen with the protective layer.

- Need to glue/fix the magnets to the wood and acrylic.

- Need to attached the red acrylic to the black one using double tape instead of clay I used in the temporarily assembly.

- Need to glue the black box together using the acrylic cement I shipped home along with the project.

- And finally, need to fasten everything together using the fasteners I purchased online.

-

Step 8: Assemble everything together permanently

Unfortunately, while I can do this step in less than half an hour, I will not be able to do it until after the course ends. That is because I packed my project in a box that was shipped home, but I will not get home until about two weeks from now as I am in quarantine at the moment, in a different city than my hometown, and will not have access to my project until after this class ends. I will send images/videos of my final project on Slack once I have it done in case anyone is curious to see how it turned out.

Total Cost of The Project:

- Acrylic (both black and red): ∼$126

- Wood stand: ∼$30

- Lazy susan: ∼$15

- Magnets: ∼$11

- Fasteners (including bolts, nuts, and spacers): ∼$28

Sum total: ∼$210

Finally, I have made a video of the temporary assembly to better visualize how the functionality and final appearance of the project would look like:

8 Comments. Leave new

Hey Abdul, I love the final product and it’s making me temped to make my own… Was there a reason you went with black and red? What was the aesthetic you were trying to accomplish? Regardless it’s very impressive what you were able to make, and great job getting an early start so that you were able to finish the project before campus closed.

Abdul! I actually did not drink coffee until this semester, and have now turned to a coffee lover. I think this project is great and very well done! Laser cutting the housing components must have saved you a bit of time. Also the step by step images in this post gave me a much better sense of your project. Great Work!

Abdul, I think this turned out really well. It seems to meet your functional requirements and needs. What was the aesthetic you were after?

Thank you Danny! The aesthetic I was going for is modern, minimalist, and sleek. Hope the assembly I made reflected that.

Hey Abdul! I hope you’re doing alright in quarantine, hang in there! I love your final project, you did such a wonderful job designing and creating it. I think you definitely accomplished the modern, sleek aesthetic. Are you worried about any of it breaking during the shipment? Or is it all pretty stable and will be okay once delivered? I can’t wait to see the final product once you can upload it. Great job Abdul!!

Thank you Hailee! I actually shipped it as flat sheets of acrylic as I would permanently assemble it once I get out of quarantine in about a week. I made sure that it is perfectly safe while shipping and I have my shipment arrived at my home safely. Can’t wait to actually assemble it when I get home!

Excellent job on thinking ahead and successfully fabricated your idea! The end product definitely looks like something that I want to buy in a store!

Best,

Xiang

Thank you Xiang! I really appreciate the comment!